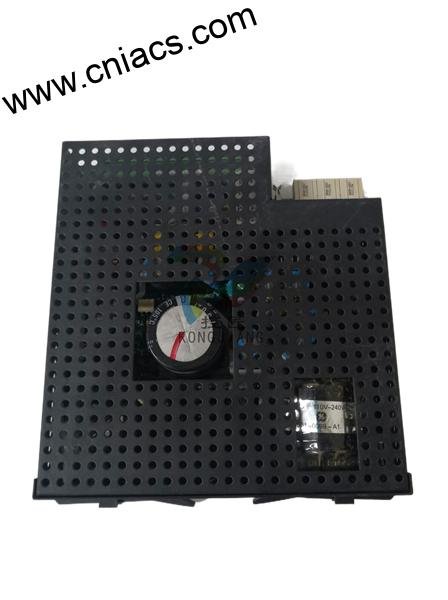

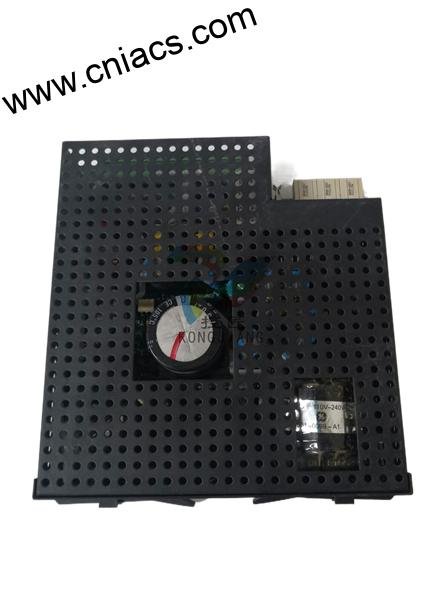

GE FANUC IC693CPU360 Central Processing Unit (CPU) 360 Module

Introducing the GE FANUC: A Pinnacle of Automation Excellence

The GE FANUC product line embodies the forefront of automation technology, delivering robust solutions tailored for a multitude of industrial applications. Renowned for their reliability and advanced features, GE FANUC products are designed to optimize processes, enhance productivity, and ensure seamless integration within existing systems. This product description explores the key technical features, usage scenarios, comparisons with other models, and related products that enhance the GE FANUC ecosystem, making it a leading choice in the realm of GE automation products.

Key Technical Features

The GE FANUC series stands out with its exceptional technical specifications that cater to a diverse range of industries. Some of the key features include:

1. **High Performance**: Designed for demanding applications, the GE FANUC models offer superior processing power and speed, ensuring quick response times and efficient operation.

2. **Scalability**: The modular design of GE FANUC products allows for easy expansion. Users can integrate additional components without overhauling the entire system, making it ideal for growing operations.

3. **Enhanced Connectivity**: With support for various communication protocols, GE FANUC products ensure seamless integration with other GE automation products and third-party devices. This connectivity is essential for modern industrial environments that rely on data exchange and real-time monitoring.

4. **Robust User Interface**: GE FANUC systems come equipped with intuitive user interfaces, which simplify operation and reduce the learning curve for new users. Operators can easily navigate through menus and settings, enhancing overall productivity.

5. **Advanced Diagnostics**: Built-in diagnostic tools provide real-time insights into system performance, allowing for proactive maintenance and minimizing downtime. Users can access detailed reports to identify potential issues before they escalate.

6. **Durable Design**: GE FANUC products are engineered to withstand harsh industrial conditions. Their rugged construction ensures reliable performance in environments with extreme temperatures, dust, and vibrations.

Usage Scenarios

The versatility of GE FANUC products makes them suitable for a wide range of applications across various industries, including:

– **Manufacturing**: In manufacturing settings, GE FANUC systems can control robotics, assembly lines, and machinery, ensuring efficient production processes and high-quality outputs.

– **Energy Management**: GE FANUC technology plays a crucial role in energy management systems, optimizing power distribution and monitoring usage to enhance sustainability practices.

– **Transportation**: Used in transportation systems, GE FANUC products can manage traffic lights, monitor vehicle flow, and contribute to intelligent

The above parameters are for reference only. Please contact our technical team for precise selection.

The GE FANUC product line embodies the forefront of automation technology, delivering robust solutions tailored for a multitude of industrial applications. Renowned for their reliability and advanced features, GE FANUC products are designed to optimize processes, enhance productivity, and ensure seamless integration within existing systems. This product description explores the key technical features, usage scenarios, comparisons with other models, and related products that enhance the GE FANUC ecosystem, making it a leading choice in the realm of GE automation products.

Key Technical Features

The GE FANUC series stands out with its exceptional technical specifications that cater to a diverse range of industries. Some of the key features include:

1. **High Performance**: Designed for demanding applications, the GE FANUC models offer superior processing power and speed, ensuring quick response times and efficient operation.

2. **Scalability**: The modular design of GE FANUC products allows for easy expansion. Users can integrate additional components without overhauling the entire system, making it ideal for growing operations.

3. **Enhanced Connectivity**: With support for various communication protocols, GE FANUC products ensure seamless integration with other GE automation products and third-party devices. This connectivity is essential for modern industrial environments that rely on data exchange and real-time monitoring.

4. **Robust User Interface**: GE FANUC systems come equipped with intuitive user interfaces, which simplify operation and reduce the learning curve for new users. Operators can easily navigate through menus and settings, enhancing overall productivity.

5. **Advanced Diagnostics**: Built-in diagnostic tools provide real-time insights into system performance, allowing for proactive maintenance and minimizing downtime. Users can access detailed reports to identify potential issues before they escalate.

6. **Durable Design**: GE FANUC products are engineered to withstand harsh industrial conditions. Their rugged construction ensures reliable performance in environments with extreme temperatures, dust, and vibrations.

Usage Scenarios

The versatility of GE FANUC products makes them suitable for a wide range of applications across various industries, including:

– **Manufacturing**: In manufacturing settings, GE FANUC systems can control robotics, assembly lines, and machinery, ensuring efficient production processes and high-quality outputs.

– **Energy Management**: GE FANUC technology plays a crucial role in energy management systems, optimizing power distribution and monitoring usage to enhance sustainability practices.

– **Transportation**: Used in transportation systems, GE FANUC products can manage traffic lights, monitor vehicle flow, and contribute to intelligent

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.