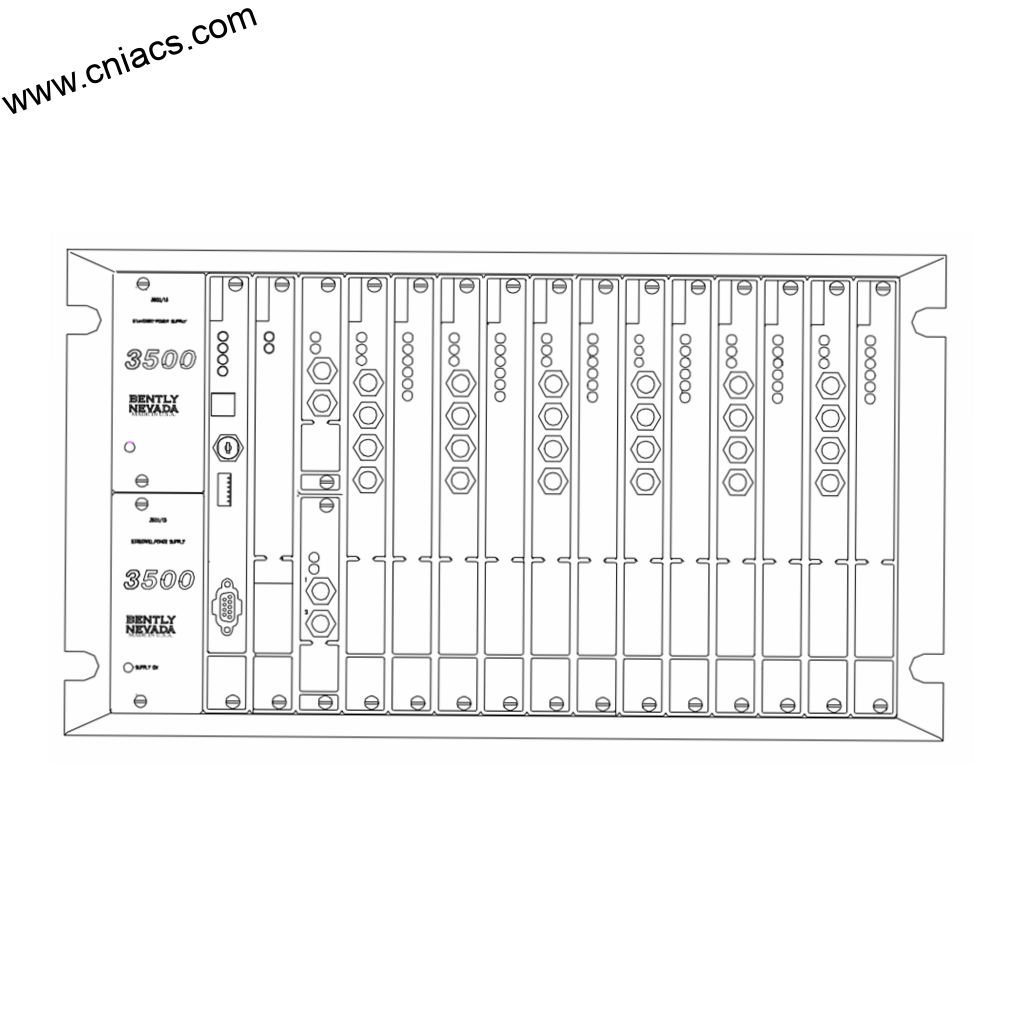

BENTLY 3500/15 133292-01 Module for Industrial Control Systems

Introducing the BENTLY 3500/15: Precision Monitoring for Enhanced Reliability

The BENTLY 3500/15 is a state-of-the-art system designed for dynamic monitoring of industrial machinery, ensuring optimal performance and reliability. As part of the esteemed BENTLY automation products line, this model excels in providing critical insights into the health of your equipment, thus enabling proactive maintenance and minimizing downtime.

Key Technical Features

The BENTLY 3500/15 boasts an impressive array of technical features designed to elevate your monitoring capabilities. Key highlights include:

1. **Advanced Signal Processing**: The BENTLY 3500/15 uses sophisticated algorithms to analyze vibration and condition monitoring data, allowing for accurate diagnostics of machinery health.

2. **Wide Frequency Range**: This model supports a broad frequency range, making it suitable for monitoring various types of machinery, including turbines, compressors, and motors.

3. **Real-time Data Acquisition**: With its real-time data acquisition capabilities, the BENTLY 3500/15 provides immediate feedback on your equipment's performance, empowering operators to make informed decisions.

4. **User-friendly Interface**: The intuitive interface of the BENTLY 3500/15 simplifies monitoring tasks, enabling users to quickly interpret data and respond to anomalies.

5. **Modular Design**: Its modular architecture allows for easy upgrades and scalability, ensuring that your monitoring system can grow alongside your business needs.

6. **Robust Connectivity**: The BENTLY 3500/15 is equipped with versatile connectivity options, facilitating seamless integration with existing systems and networks.

Usage Scenarios

The BENTLY 3500/15 is ideal for various industrial applications where machinery reliability is paramount. Below are a few scenarios in which this model excels:

– **Power Generation**: In power plants, the BENTLY 3500/15 monitors critical equipment like steam turbines and generators, ensuring they operate efficiently and safely.

– **Oil and Gas**: In the oil and gas sector, this model is employed to monitor pumps and compressors, detecting issues before they lead to costly failures.

– **Manufacturing**: In manufacturing environments, the BENTLY 3500/15 provides ongoing diagnostics for assembly line machinery, maximizing throughput and minimizing unexpected downtime.

– **Marine Applications**: The BENTLY 3500/15 is also valuable in marine applications, offering real-time condition monitoring for propulsion systems and auxiliary machinery.

Comparison with Other Models

The above parameters are for reference only. Please contact our technical team for precise selection.

The BENTLY 3500/15 is a state-of-the-art system designed for dynamic monitoring of industrial machinery, ensuring optimal performance and reliability. As part of the esteemed BENTLY automation products line, this model excels in providing critical insights into the health of your equipment, thus enabling proactive maintenance and minimizing downtime.

Key Technical Features

The BENTLY 3500/15 boasts an impressive array of technical features designed to elevate your monitoring capabilities. Key highlights include:

1. **Advanced Signal Processing**: The BENTLY 3500/15 uses sophisticated algorithms to analyze vibration and condition monitoring data, allowing for accurate diagnostics of machinery health.

2. **Wide Frequency Range**: This model supports a broad frequency range, making it suitable for monitoring various types of machinery, including turbines, compressors, and motors.

3. **Real-time Data Acquisition**: With its real-time data acquisition capabilities, the BENTLY 3500/15 provides immediate feedback on your equipment's performance, empowering operators to make informed decisions.

4. **User-friendly Interface**: The intuitive interface of the BENTLY 3500/15 simplifies monitoring tasks, enabling users to quickly interpret data and respond to anomalies.

5. **Modular Design**: Its modular architecture allows for easy upgrades and scalability, ensuring that your monitoring system can grow alongside your business needs.

6. **Robust Connectivity**: The BENTLY 3500/15 is equipped with versatile connectivity options, facilitating seamless integration with existing systems and networks.

Usage Scenarios

The BENTLY 3500/15 is ideal for various industrial applications where machinery reliability is paramount. Below are a few scenarios in which this model excels:

– **Power Generation**: In power plants, the BENTLY 3500/15 monitors critical equipment like steam turbines and generators, ensuring they operate efficiently and safely.

– **Oil and Gas**: In the oil and gas sector, this model is employed to monitor pumps and compressors, detecting issues before they lead to costly failures.

– **Manufacturing**: In manufacturing environments, the BENTLY 3500/15 provides ongoing diagnostics for assembly line machinery, maximizing throughput and minimizing unexpected downtime.

– **Marine Applications**: The BENTLY 3500/15 is also valuable in marine applications, offering real-time condition monitoring for propulsion systems and auxiliary machinery.

Comparison with Other Models

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.jpg?v=1739320885)

There are no reviews yet.