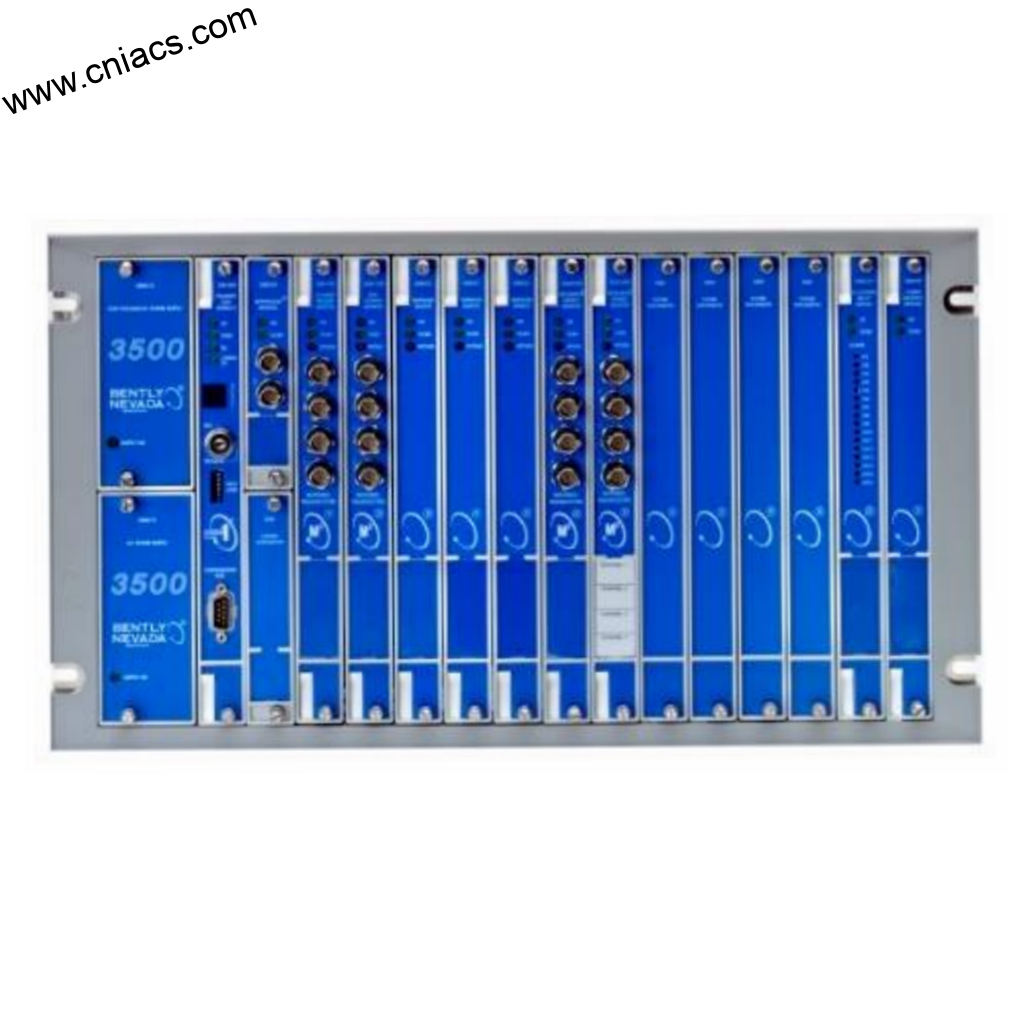

BENTLY 330102-20-55-10-02-CN Vibration Monitoring System

Introducing the BENTLY 330102-20-55-10-02-CN, a state-of-the-art monitoring solution designed to enhance the efficiency and reliability of your industrial systems. This model stands as a testament to BENTLY's commitment to providing top-tier automation products that integrate seamlessly into various applications.

Key Technical Features

The BENTLY 330102-20-55-10-02-CN is engineered with high precision and reliability at its core. Key features include:

1. **Advanced Vibration Monitoring**: This model offers unparalleled vibration analysis capabilities, ensuring that any anomalies are detected early, allowing for proactive maintenance and reduced downtime.

2. **Real-Time Data Acquisition**: The BENTLY 330102-20-55-10-02-CN collects real-time data, enabling operators to monitor performance metrics continuously. This feature is essential for maintaining optimal operational efficiency and safety.

3. **Robust Design**: Built to withstand harsh industrial environments, the BENTLY 330102-20-55-10-02-CN is designed with durable materials and components that ensure longevity and reliability, even in the most demanding conditions.

4. **User-Friendly Interface**: The intuitive interface allows for easy navigation and configuration, making it accessible for operators at all skill levels.

5. **Compatibility**: This model is compatible with a wide range of BENTLY automation products, allowing for easy integration into existing systems without the need for extensive modifications.

Usage Scenarios

The BENTLY 330102-20-55-10-02-CN is versatile and can be utilized across various industries. Here are a few scenarios where this model excels:

1. **Power Generation**: In power plants, the BENTLY 330102-20-55-10-02-CN monitors turbine vibrations, ensuring that any potential issues are identified before they escalate into costly failures.

2. **Oil and Gas**: The model is crucial for monitoring pumps and compressors, where vibration analysis helps in preventing equipment failure, ensuring safety and efficiency in extraction and processing operations.

3. **Manufacturing**: In manufacturing facilities, the BENTLY 330102-20-55-10-02-CN plays a critical role in ensuring the reliability of rotating machinery, thereby minimizing unplanned downtime and enhancing productivity.

4. **Mining**: The rugged construction of this model makes it suitable for mining applications, where it can monitor the performance of heavy

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY 330102-20-55-10-02-CN is engineered with high precision and reliability at its core. Key features include:

1. **Advanced Vibration Monitoring**: This model offers unparalleled vibration analysis capabilities, ensuring that any anomalies are detected early, allowing for proactive maintenance and reduced downtime.

2. **Real-Time Data Acquisition**: The BENTLY 330102-20-55-10-02-CN collects real-time data, enabling operators to monitor performance metrics continuously. This feature is essential for maintaining optimal operational efficiency and safety.

3. **Robust Design**: Built to withstand harsh industrial environments, the BENTLY 330102-20-55-10-02-CN is designed with durable materials and components that ensure longevity and reliability, even in the most demanding conditions.

4. **User-Friendly Interface**: The intuitive interface allows for easy navigation and configuration, making it accessible for operators at all skill levels.

5. **Compatibility**: This model is compatible with a wide range of BENTLY automation products, allowing for easy integration into existing systems without the need for extensive modifications.

Usage Scenarios

The BENTLY 330102-20-55-10-02-CN is versatile and can be utilized across various industries. Here are a few scenarios where this model excels:

1. **Power Generation**: In power plants, the BENTLY 330102-20-55-10-02-CN monitors turbine vibrations, ensuring that any potential issues are identified before they escalate into costly failures.

2. **Oil and Gas**: The model is crucial for monitoring pumps and compressors, where vibration analysis helps in preventing equipment failure, ensuring safety and efficiency in extraction and processing operations.

3. **Manufacturing**: In manufacturing facilities, the BENTLY 330102-20-55-10-02-CN plays a critical role in ensuring the reliability of rotating machinery, thereby minimizing unplanned downtime and enhancing productivity.

4. **Mining**: The rugged construction of this model makes it suitable for mining applications, where it can monitor the performance of heavy

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.png?v=1739321128)

There are no reviews yet.