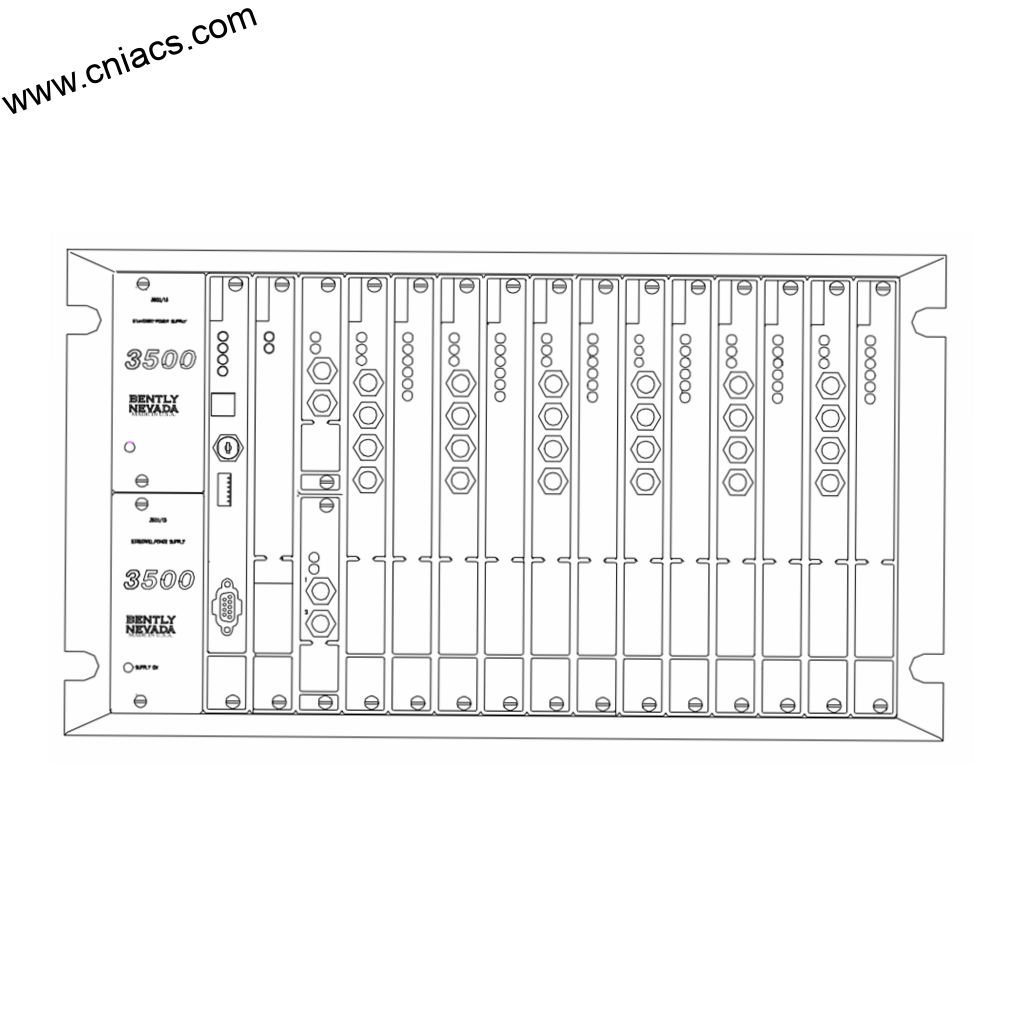

BENTLY 330100-90-01 Vibration Monitoring System Module

Introducing the BENTLY 330100-90-01, a robust and highly reliable component in the extensive lineup of BENTLY automation products. This model stands as a testament to BENTLY's commitment to providing high-performance solutions tailored for condition monitoring and machinery protection. Designed for both versatility and durability, the BENTLY 330100-90-01 is essential for industries that prioritize operational efficiency and equipment reliability.

**Key Technical Features:**

The BENTLY 330100-90-01 is engineered with a variety of advanced technical features that elevate its performance capabilities. At its core, this model incorporates sophisticated signal processing technology, which ensures accurate data collection and analysis. The device supports a wide range of input types, making it adaptable for different types of sensors and machinery setups.

One of the standout features of the BENTLY 330100-90-01 is its high-speed data acquisition capability, which allows for real-time monitoring of machine conditions. This model is equipped with enhanced noise filtering and signal conditioning, ensuring that the data collected is both precise and reliable. Additionally, the BENTLY 330100-90-01 is designed with user-friendly interface options, allowing for seamless integration with existing systems and easy configuration adjustments.

The BENTLY 330100-90-01 also boasts extensive protocol support, enabling communication with various automation systems. This compatibility is critical for organizations looking to implement a holistic approach to machine monitoring and data management. Furthermore, its robust construction ensures it can withstand harsh industrial environments, making it suitable for a variety of applications.

**Usage Scenarios:**

The versatility of the BENTLY 330100-90-01 makes it ideal for a wide array of usage scenarios. It is particularly beneficial in industries such as oil and gas, power generation, and manufacturing, where machinery uptime and operational efficiency are paramount. Operators can use this model for vibration monitoring, temperature measurement, and overall condition assessment of rotating equipment.

In power generation facilities, for example, the BENTLY 330100-90-01 can be deployed for monitoring turbine health, helping to prevent failures that could lead to costly downtime. Similarly, in manufacturing plants, this model can be utilized to oversee conveyor systems and motors, ensuring that any anomalies are detected early, thus mitigating the risk of equipment breakdown.

Moreover, the BENTLY 330100-90-01 is an integral part of predictive maintenance strategies. By continuously monitoring machine conditions, organizations can schedule maintenance activities based on

The above parameters are for reference only. Please contact our technical team for precise selection.

**Key Technical Features:**

The BENTLY 330100-90-01 is engineered with a variety of advanced technical features that elevate its performance capabilities. At its core, this model incorporates sophisticated signal processing technology, which ensures accurate data collection and analysis. The device supports a wide range of input types, making it adaptable for different types of sensors and machinery setups.

One of the standout features of the BENTLY 330100-90-01 is its high-speed data acquisition capability, which allows for real-time monitoring of machine conditions. This model is equipped with enhanced noise filtering and signal conditioning, ensuring that the data collected is both precise and reliable. Additionally, the BENTLY 330100-90-01 is designed with user-friendly interface options, allowing for seamless integration with existing systems and easy configuration adjustments.

The BENTLY 330100-90-01 also boasts extensive protocol support, enabling communication with various automation systems. This compatibility is critical for organizations looking to implement a holistic approach to machine monitoring and data management. Furthermore, its robust construction ensures it can withstand harsh industrial environments, making it suitable for a variety of applications.

**Usage Scenarios:**

The versatility of the BENTLY 330100-90-01 makes it ideal for a wide array of usage scenarios. It is particularly beneficial in industries such as oil and gas, power generation, and manufacturing, where machinery uptime and operational efficiency are paramount. Operators can use this model for vibration monitoring, temperature measurement, and overall condition assessment of rotating equipment.

In power generation facilities, for example, the BENTLY 330100-90-01 can be deployed for monitoring turbine health, helping to prevent failures that could lead to costly downtime. Similarly, in manufacturing plants, this model can be utilized to oversee conveyor systems and motors, ensuring that any anomalies are detected early, thus mitigating the risk of equipment breakdown.

Moreover, the BENTLY 330100-90-01 is an integral part of predictive maintenance strategies. By continuously monitoring machine conditions, organizations can schedule maintenance activities based on

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.png?v=1739321122)

There are no reviews yet.