BENTLY 3500/70M Vibration Monitoring Module

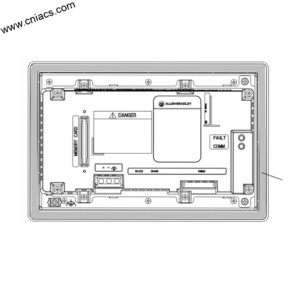

Introducing the BENTLY 3500/70M, a cutting-edge component of the renowned BENTLY automation products line. Designed for performance and reliability, the 3500/70M provides advanced monitoring and protection capabilities essential for industrial applications, particularly in complex machinery and rotating equipment. This product stands out in its class by integrating innovative features that elevate operational efficiency and safeguard critical assets.

Key Technical Features:

The BENTLY 3500/70M is equipped with state-of-the-art technology that enhances its monitoring capabilities. With its high-resolution data acquisition system, it supports up to 16 channels of simultaneous measurement, allowing for comprehensive monitoring of various parameters, including vibration, temperature, and speed. The device features a user-friendly interface that simplifies configuration and data analysis, enabling quick troubleshooting and maintenance.

The 3500/70M is designed to withstand harsh industrial environments, featuring robust housing that protects against dust, moisture, and temperature fluctuations. It operates seamlessly with a wide range of sensors, ensuring accurate real-time data collection. With a high sampling rate and advanced algorithms, the BENTLY 3500/70M delivers precise insights into machinery health, enabling predictive maintenance strategies that minimize downtime and extend equipment lifespan.

Usage Scenarios:

The versatility of the BENTLY 3500/70M makes it suitable for various applications across multiple industries. In the oil and gas sector, it is instrumental in monitoring rotating equipment such as pumps, compressors, and turbines, where early detection of mechanical issues can prevent costly failures. In power generation, the 3500/70M ensures the reliability of critical components, safeguarding against unexpected outages and enhancing operational efficiency.

In manufacturing, this model plays a vital role in process automation, providing real-time data that informs operational decisions. Its ability to integrate with existing control systems allows for streamlined workflows and improved production rates. Additionally, in the transportation sector, the BENTLY 3500/70M monitors the health of engines and rotating machinery, ensuring safety and reliability in critical applications.

Comparison with Other Models:

When compared to other models in the BENTLY automation products range, the 3500/70M excels in its channel capacity and advanced data processing capabilities. For instance, while the BENTLY 3500/20 focuses primarily on vibration monitoring with fewer channels, the 3500/70M offers a more comprehensive monitoring solution suitable for complex machinery with diverse monitoring needs.

Similarly, the BENTLY 3500/45 provides excellent

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The BENTLY 3500/70M is equipped with state-of-the-art technology that enhances its monitoring capabilities. With its high-resolution data acquisition system, it supports up to 16 channels of simultaneous measurement, allowing for comprehensive monitoring of various parameters, including vibration, temperature, and speed. The device features a user-friendly interface that simplifies configuration and data analysis, enabling quick troubleshooting and maintenance.

The 3500/70M is designed to withstand harsh industrial environments, featuring robust housing that protects against dust, moisture, and temperature fluctuations. It operates seamlessly with a wide range of sensors, ensuring accurate real-time data collection. With a high sampling rate and advanced algorithms, the BENTLY 3500/70M delivers precise insights into machinery health, enabling predictive maintenance strategies that minimize downtime and extend equipment lifespan.

Usage Scenarios:

The versatility of the BENTLY 3500/70M makes it suitable for various applications across multiple industries. In the oil and gas sector, it is instrumental in monitoring rotating equipment such as pumps, compressors, and turbines, where early detection of mechanical issues can prevent costly failures. In power generation, the 3500/70M ensures the reliability of critical components, safeguarding against unexpected outages and enhancing operational efficiency.

In manufacturing, this model plays a vital role in process automation, providing real-time data that informs operational decisions. Its ability to integrate with existing control systems allows for streamlined workflows and improved production rates. Additionally, in the transportation sector, the BENTLY 3500/70M monitors the health of engines and rotating machinery, ensuring safety and reliability in critical applications.

Comparison with Other Models:

When compared to other models in the BENTLY automation products range, the 3500/70M excels in its channel capacity and advanced data processing capabilities. For instance, while the BENTLY 3500/20 focuses primarily on vibration monitoring with fewer channels, the 3500/70M offers a more comprehensive monitoring solution suitable for complex machinery with diverse monitoring needs.

Similarly, the BENTLY 3500/45 provides excellent

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.jpg?v=1739237723)

There are no reviews yet.