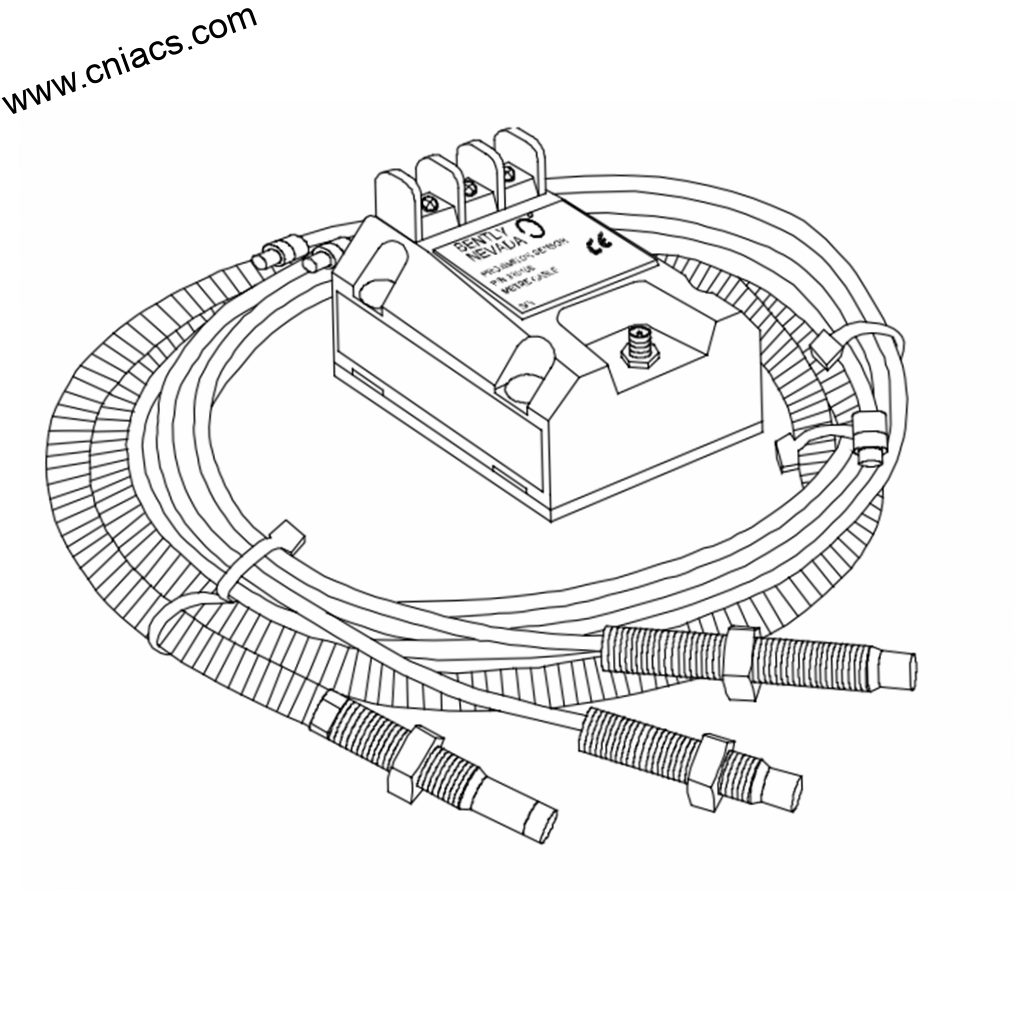

BENTLY Nevada 3500/25 (125800-01) Advanced Automation Module for Industrial Control Systems

Introducing the BENTLY Nevada 3500/25 (125800-01), a premier solution in the realm of condition monitoring and diagnostics for industrial machinery. As part of the acclaimed BENTLY automation products line, the 3500/25 model is designed to deliver unparalleled performance, reliability, and precision in monitoring the health of rotating machinery.

Key Technical Features

The BENTLY Nevada 3500/25 (125800-01) is engineered with advanced technology to provide comprehensive monitoring capabilities. Key features include:

1. **Multi-channel Support**: The 3500/25 supports up to 16 channels of data collection, allowing it to monitor multiple parameters such as vibration, temperature, and speed simultaneously.

2. **High-Accuracy Measurements**: With its cutting-edge sensor technology, the 3500/25 offers high-accuracy measurements, ensuring that users receive precise data for effective decision-making.

3. **Real-Time Data Processing**: The model boasts real-time data processing capabilities, enabling immediate diagnostics and condition assessment, which is critical in preventing potential failures.

4. **User-Friendly Interface**: Equipped with an intuitive interface, the 3500/25 allows for straightforward operation, making it accessible for both experienced technicians and new users alike.

5. **Robust Build Quality**: Designed to withstand harsh industrial environments, the 3500/25 features a rugged construction that ensures longevity and reliable performance, even in the most challenging conditions.

6. **Flexible Integration**: The BENTLY Nevada 3500/25 can easily integrate with other BENTLY automation products, providing a cohesive monitoring solution across various systems.

Usage Scenarios

The versatility of the BENTLY Nevada 3500/25 makes it ideal for a wide range of industrial applications. It is particularly beneficial in sectors such as:

1. **Oil and Gas**: Monitor critical assets like pumps and compressors to prevent costly downtime and enhance operational efficiency.

2. **Power Generation**: Ensure the reliability of turbines and generators through continuous monitoring, allowing for timely maintenance interventions.

3. **Manufacturing**: Track the health of rotating equipment in production lines, minimizing unplanned outages and improving productivity.

4. **Mining**: Monitor conveyor systems and crushers to maintain smooth operations and reduce maintenance costs.

5. **Water and Wastewater Treatment**: Keep pumps and motors in check to ensure consistent performance and compliance with regulatory standards.

Comparison with Other Models

When comparing the BENTLY Nevada

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY Nevada 3500/25 (125800-01) is engineered with advanced technology to provide comprehensive monitoring capabilities. Key features include:

1. **Multi-channel Support**: The 3500/25 supports up to 16 channels of data collection, allowing it to monitor multiple parameters such as vibration, temperature, and speed simultaneously.

2. **High-Accuracy Measurements**: With its cutting-edge sensor technology, the 3500/25 offers high-accuracy measurements, ensuring that users receive precise data for effective decision-making.

3. **Real-Time Data Processing**: The model boasts real-time data processing capabilities, enabling immediate diagnostics and condition assessment, which is critical in preventing potential failures.

4. **User-Friendly Interface**: Equipped with an intuitive interface, the 3500/25 allows for straightforward operation, making it accessible for both experienced technicians and new users alike.

5. **Robust Build Quality**: Designed to withstand harsh industrial environments, the 3500/25 features a rugged construction that ensures longevity and reliable performance, even in the most challenging conditions.

6. **Flexible Integration**: The BENTLY Nevada 3500/25 can easily integrate with other BENTLY automation products, providing a cohesive monitoring solution across various systems.

Usage Scenarios

The versatility of the BENTLY Nevada 3500/25 makes it ideal for a wide range of industrial applications. It is particularly beneficial in sectors such as:

1. **Oil and Gas**: Monitor critical assets like pumps and compressors to prevent costly downtime and enhance operational efficiency.

2. **Power Generation**: Ensure the reliability of turbines and generators through continuous monitoring, allowing for timely maintenance interventions.

3. **Manufacturing**: Track the health of rotating equipment in production lines, minimizing unplanned outages and improving productivity.

4. **Mining**: Monitor conveyor systems and crushers to maintain smooth operations and reduce maintenance costs.

5. **Water and Wastewater Treatment**: Keep pumps and motors in check to ensure consistent performance and compliance with regulatory standards.

Comparison with Other Models

When comparing the BENTLY Nevada

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.