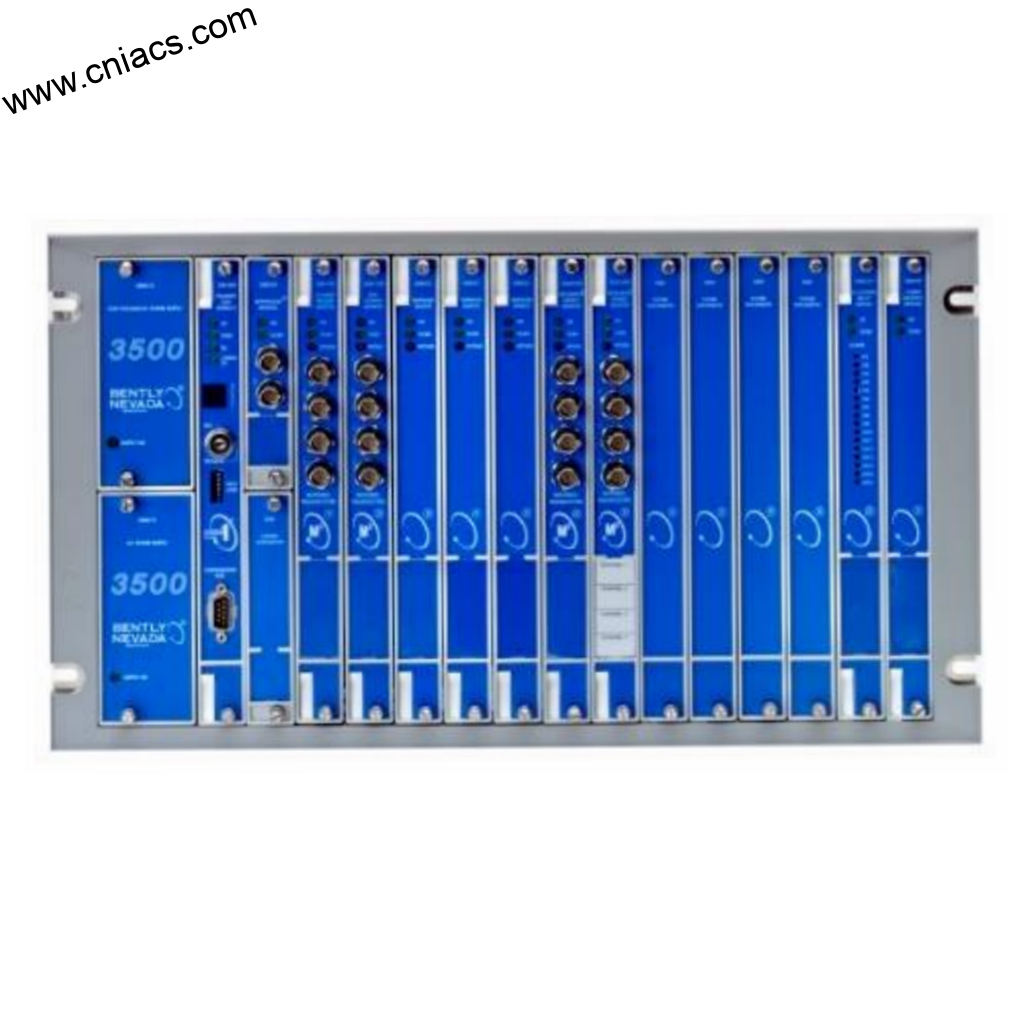

BENTLY Nevada 3300/35-12-02-02-00-02, Advanced Automation Solution

Introducing the BENTLY Nevada, a pinnacle of engineering excellence in the realm of industrial monitoring and automation. With a robust design and cutting-edge technology, the BENTLY Nevada is engineered to enhance the reliability and efficiency of your operations. It stands out in the field of BENTLY automation products, providing critical data and insights that empower organizations to optimize their performance and ensure the longevity of their assets.

Key Technical Features

The BENTLY Nevada offers a plethora of technical features that make it an indispensable tool for industries requiring precise monitoring and diagnostics. At its core, the system includes advanced vibration sensors and data acquisition capabilities that allow for real-time monitoring of machinery health. This model is equipped with sophisticated algorithms designed to detect anomalies and predict potential failures, enabling proactive maintenance strategies.

One of the standout features of the BENTLY Nevada is its scalability. Whether you're monitoring a single asset or an entire fleet of machinery, the system can be tailored to meet your specific needs. Moreover, it supports multiple input types and can integrate seamlessly with existing systems, ensuring that you can expand your monitoring capabilities without overhauling your infrastructure.

Additionally, the BENTLY Nevada boasts user-friendly software that provides intuitive dashboards and detailed reporting features. This software allows operators to easily visualize data trends, making it straightforward to interpret complex information. With customizable alerts and notifications, users are promptly informed of any critical changes in machinery performance, allowing for swift action to mitigate risks.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for various industrial applications. From power generation plants to oil and gas facilities, this model is designed to monitor rotating equipment, including turbines, generators, and compressors. In manufacturing environments, it plays a crucial role in ensuring that production lines operate smoothly, minimizing downtime and maximizing productivity.

In the aerospace sector, the BENTLY Nevada is utilized for monitoring aircraft engines, where precision is vital. Its ability to provide real-time data on engine performance and health helps ensure safety and compliance with stringent regulations. Similarly, in the marine industry, the BENTLY Nevada is employed to monitor propulsion systems, ensuring optimal operation during voyages.

Furthermore, the system is invaluable in the mining sector, where equipment reliability is paramount. By continuously monitoring the health of critical machinery, mining operations can reduce the likelihood of unexpected failures, leading to enhanced safety and operational efficiency.

Comparison with Other Models

When comparing the BENTLY Nevada to other models within the BENTLY suite, such as the BENTLY 3500

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY Nevada offers a plethora of technical features that make it an indispensable tool for industries requiring precise monitoring and diagnostics. At its core, the system includes advanced vibration sensors and data acquisition capabilities that allow for real-time monitoring of machinery health. This model is equipped with sophisticated algorithms designed to detect anomalies and predict potential failures, enabling proactive maintenance strategies.

One of the standout features of the BENTLY Nevada is its scalability. Whether you're monitoring a single asset or an entire fleet of machinery, the system can be tailored to meet your specific needs. Moreover, it supports multiple input types and can integrate seamlessly with existing systems, ensuring that you can expand your monitoring capabilities without overhauling your infrastructure.

Additionally, the BENTLY Nevada boasts user-friendly software that provides intuitive dashboards and detailed reporting features. This software allows operators to easily visualize data trends, making it straightforward to interpret complex information. With customizable alerts and notifications, users are promptly informed of any critical changes in machinery performance, allowing for swift action to mitigate risks.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for various industrial applications. From power generation plants to oil and gas facilities, this model is designed to monitor rotating equipment, including turbines, generators, and compressors. In manufacturing environments, it plays a crucial role in ensuring that production lines operate smoothly, minimizing downtime and maximizing productivity.

In the aerospace sector, the BENTLY Nevada is utilized for monitoring aircraft engines, where precision is vital. Its ability to provide real-time data on engine performance and health helps ensure safety and compliance with stringent regulations. Similarly, in the marine industry, the BENTLY Nevada is employed to monitor propulsion systems, ensuring optimal operation during voyages.

Furthermore, the system is invaluable in the mining sector, where equipment reliability is paramount. By continuously monitoring the health of critical machinery, mining operations can reduce the likelihood of unexpected failures, leading to enhanced safety and operational efficiency.

Comparison with Other Models

When comparing the BENTLY Nevada to other models within the BENTLY suite, such as the BENTLY 3500

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.png?v=1739321142)

There are no reviews yet.