BENTLY Nevada 3500/33-01-CN; Manufacturer bently-nevada

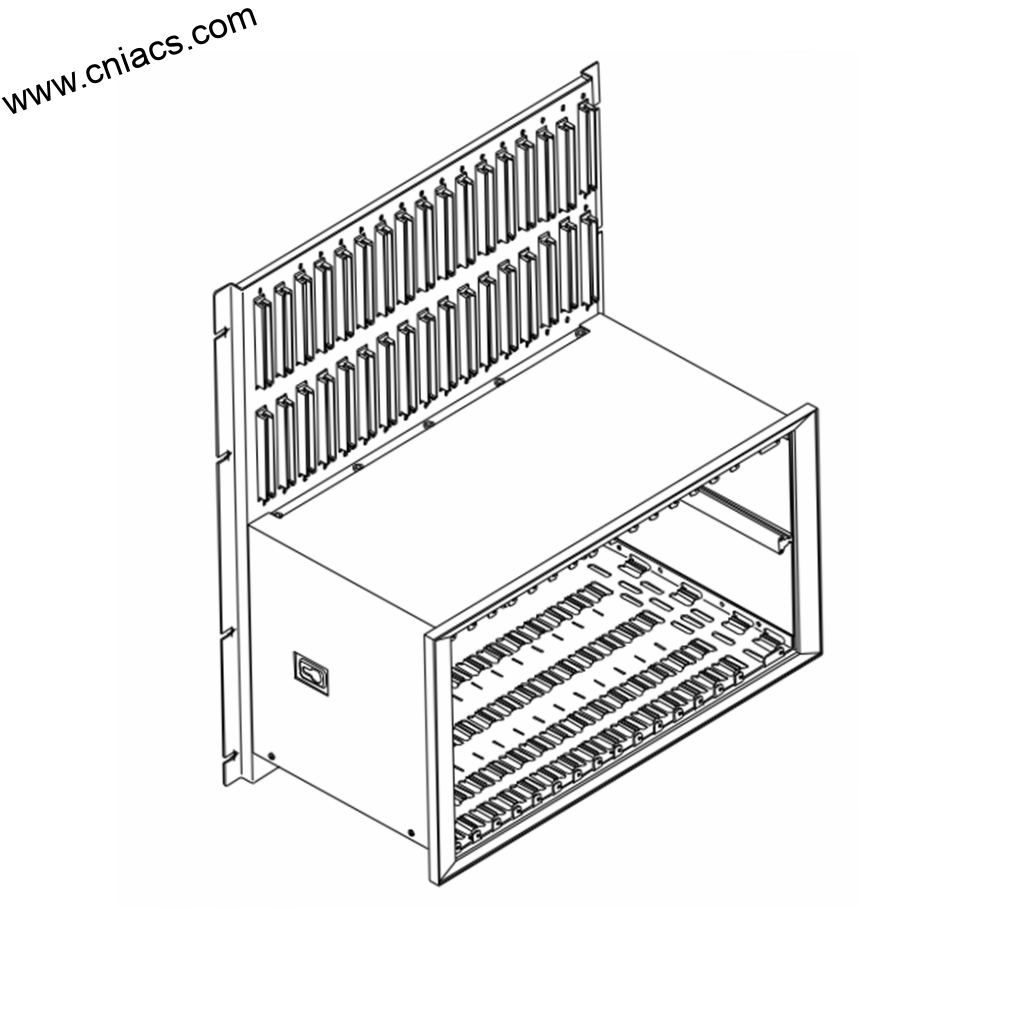

Introducing the BENTLY Nevada 3500/33-01-CN, a premier monitoring solution designed to meet the demanding requirements of industrial applications. As part of the BENTLY automation products lineup, this model delivers unparalleled performance, reliability, and ease of integration, making it an essential choice for professionals in various sectors, including oil and gas, power generation, and manufacturing.

Key Technical Features

The BENTLY Nevada 3500/33-01-CN boasts an impressive array of technical features that set it apart from its competitors. At its core, this model is designed for vibration monitoring and machinery protection, ensuring optimal performance of rotating equipment. It incorporates advanced signal processing capabilities, which enable high-resolution data acquisition and analysis, allowing for early fault detection and minimization of unplanned downtime.

One of the standout features of the 3500/33-01-CN is its ability to support both dynamic and static measurements. This versatility is essential for users who require comprehensive monitoring solutions tailored to their specific operational needs. The unit also features built-in diagnostics and self-testing capabilities, ensuring continuous operation and reliability in the most challenging environments.

The BENTLY Nevada 3500/33-01-CN comes equipped with a user-friendly interface, facilitating easy configuration and monitoring. Its modular design ensures seamless integration with other BENTLY automation products, enabling users to create a tailored monitoring system that meets their unique requirements. Additionally, its robust construction guarantees durability, ensuring long-lasting performance even in harsh conditions.

Usage Scenarios

The BENTLY Nevada 3500/33-01-CN is ideal for a wide range of industrial applications. In the oil and gas sector, this model excels in monitoring critical rotating machinery such as pumps, compressors, and turbines, helping to prevent catastrophic failures that can lead to significant financial losses and safety hazards. Similarly, in power generation facilities, the 3500/33-01-CN plays a crucial role in ensuring the reliability of generators and other vital equipment.

Manufacturers across various industries also benefit significantly from the 3500/33-01-CN, as it allows for predictive maintenance strategies that optimize equipment performance and extend operational life. By providing real-time data and insights, this model empowers maintenance teams to make informed decisions and implement timely interventions.

Comparison with Other Models

When compared to other models in the BENTLY lineup, such as the BENTLY 3500/20 125744-02 and BENTLY 3500/

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY Nevada 3500/33-01-CN boasts an impressive array of technical features that set it apart from its competitors. At its core, this model is designed for vibration monitoring and machinery protection, ensuring optimal performance of rotating equipment. It incorporates advanced signal processing capabilities, which enable high-resolution data acquisition and analysis, allowing for early fault detection and minimization of unplanned downtime.

One of the standout features of the 3500/33-01-CN is its ability to support both dynamic and static measurements. This versatility is essential for users who require comprehensive monitoring solutions tailored to their specific operational needs. The unit also features built-in diagnostics and self-testing capabilities, ensuring continuous operation and reliability in the most challenging environments.

The BENTLY Nevada 3500/33-01-CN comes equipped with a user-friendly interface, facilitating easy configuration and monitoring. Its modular design ensures seamless integration with other BENTLY automation products, enabling users to create a tailored monitoring system that meets their unique requirements. Additionally, its robust construction guarantees durability, ensuring long-lasting performance even in harsh conditions.

Usage Scenarios

The BENTLY Nevada 3500/33-01-CN is ideal for a wide range of industrial applications. In the oil and gas sector, this model excels in monitoring critical rotating machinery such as pumps, compressors, and turbines, helping to prevent catastrophic failures that can lead to significant financial losses and safety hazards. Similarly, in power generation facilities, the 3500/33-01-CN plays a crucial role in ensuring the reliability of generators and other vital equipment.

Manufacturers across various industries also benefit significantly from the 3500/33-01-CN, as it allows for predictive maintenance strategies that optimize equipment performance and extend operational life. By providing real-time data and insights, this model empowers maintenance teams to make informed decisions and implement timely interventions.

Comparison with Other Models

When compared to other models in the BENTLY lineup, such as the BENTLY 3500/20 125744-02 and BENTLY 3500/

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.