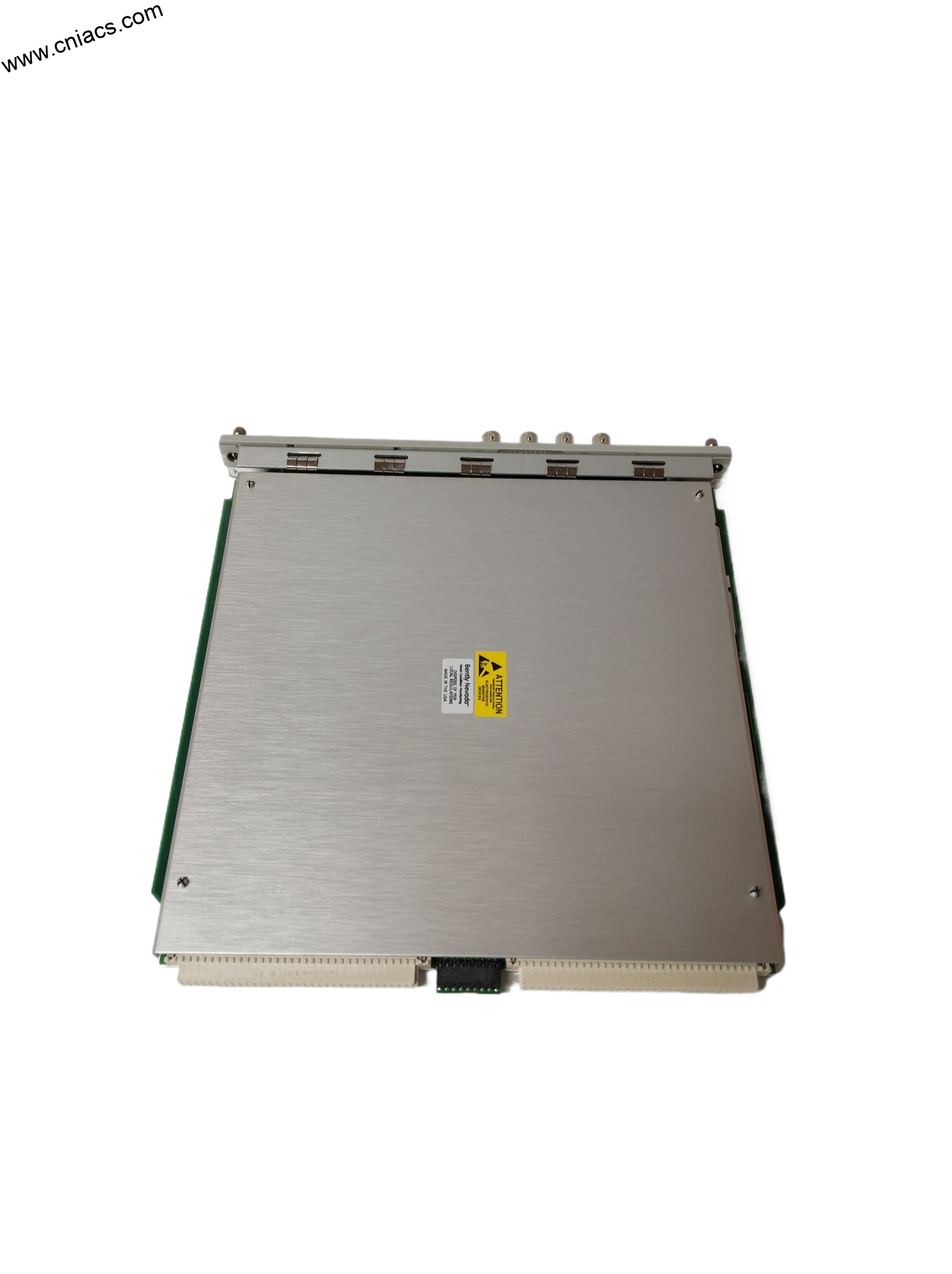

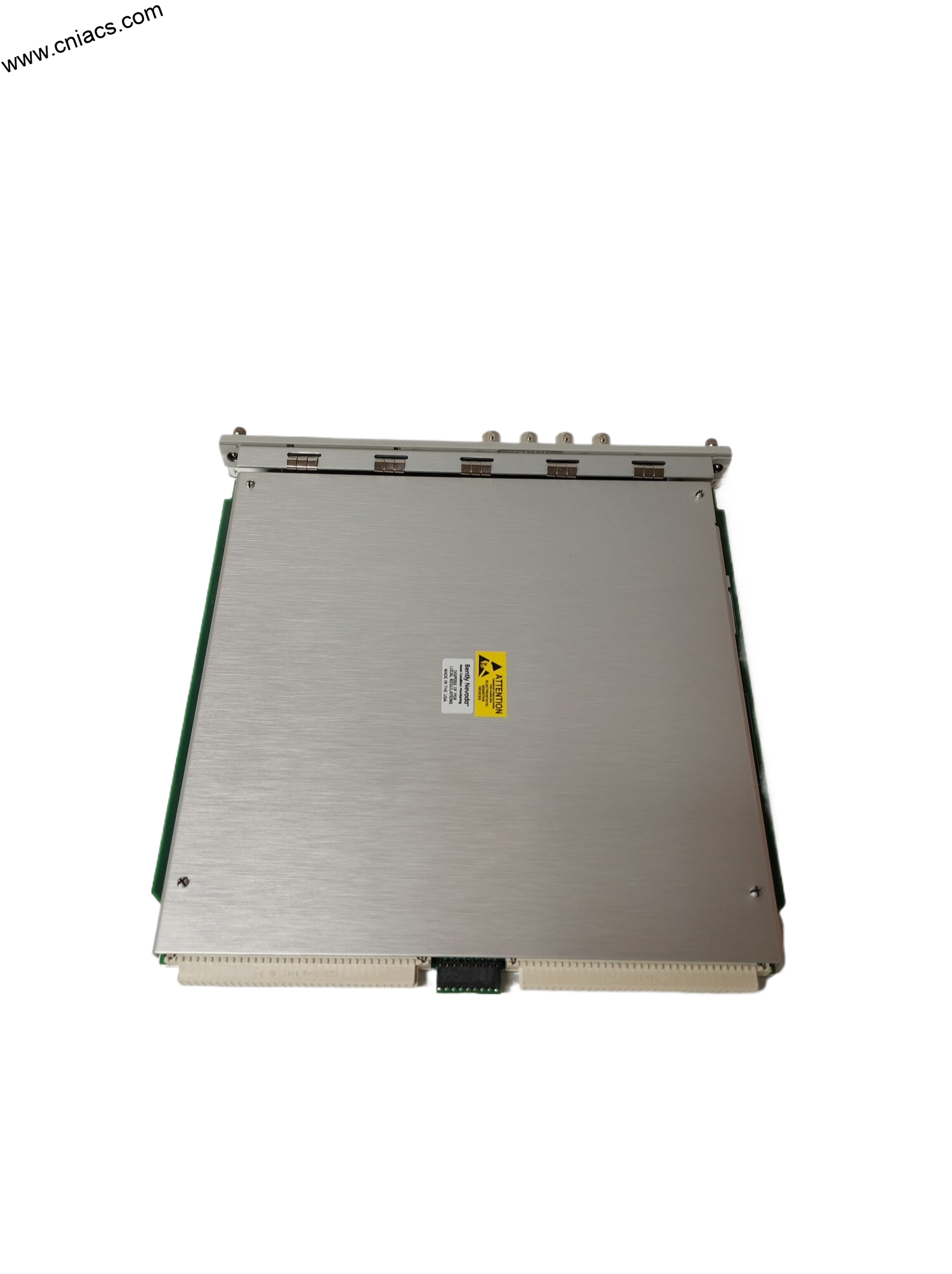

BENTLY Nevada 330130-045-03-05 Standard Extension Cable; Manufacturer:bently-nevada

Introducing the BENTLY Nevada: A Pinnacle of Reliability and Precision in Machinery Protection

In the world of industrial automation and machinery protection, the BENTLY Nevada series is synonymous with excellence. Designed with cutting-edge technology, the BENTLY Nevada offers unmatched reliability and performance for various industrial applications. This product description delves into the key technical features, usage scenarios, comparisons with other models, and highlights related products within the BENTLY family, demonstrating why the BENTLY Nevada is a top choice for engineers and facility managers alike.

Key Technical Features

The BENTLY Nevada is engineered for superior performance in monitoring and protecting rotating machinery. Here are some of its standout technical features:

1. **Advanced Monitoring Capabilities**: The BENTLY Nevada utilizes sophisticated sensors and algorithms to monitor vibrations, temperatures, and other critical parameters in real time. This data-driven approach ensures the early detection of potential issues, allowing for timely maintenance and minimizing downtime.

2. **Robust Design**: Built to withstand harsh industrial environments, the BENTLY Nevada is constructed from high-quality materials that resist corrosion, high temperatures, and physical shocks. This durability ensures long-lasting performance, even in the most demanding applications.

3. **Scalability and Flexibility**: The modular design of the BENTLY Nevada allows for easy scalability. Whether you have a single machine or an extensive fleet of equipment, the system can be customized to meet your specific monitoring needs.

4. **Seamless Integration**: As part of the BENTLY automation products line, the Nevada can easily integrate with existing control systems and other BENTLY models, providing a comprehensive solution for machinery protection and monitoring.

5. **User-Friendly Interface**: The BENTLY Nevada features an intuitive interface that simplifies configuration and operation. Users can quickly access critical data and make adjustments with minimal training, enhancing overall productivity.

Usage Scenarios

The BENTLY Nevada is versatile and can be applied across various industries and applications, including:

1. **Power Generation**: In power plants, the BENTLY Nevada monitors turbines and generators, ensuring optimal performance and safeguarding against failures that could lead to costly outages.

2. **Oil and Gas**: In the oil and gas sector, this model is crucial for monitoring pumps, compressors, and turbines, helping to prevent catastrophic failures and environmental incidents.

3. **Mining**: The rugged design of the BENTLY Nevada makes it ideal for the mining industry, where equipment operates in

The above parameters are for reference only. Please contact our technical team for precise selection.

In the world of industrial automation and machinery protection, the BENTLY Nevada series is synonymous with excellence. Designed with cutting-edge technology, the BENTLY Nevada offers unmatched reliability and performance for various industrial applications. This product description delves into the key technical features, usage scenarios, comparisons with other models, and highlights related products within the BENTLY family, demonstrating why the BENTLY Nevada is a top choice for engineers and facility managers alike.

Key Technical Features

The BENTLY Nevada is engineered for superior performance in monitoring and protecting rotating machinery. Here are some of its standout technical features:

1. **Advanced Monitoring Capabilities**: The BENTLY Nevada utilizes sophisticated sensors and algorithms to monitor vibrations, temperatures, and other critical parameters in real time. This data-driven approach ensures the early detection of potential issues, allowing for timely maintenance and minimizing downtime.

2. **Robust Design**: Built to withstand harsh industrial environments, the BENTLY Nevada is constructed from high-quality materials that resist corrosion, high temperatures, and physical shocks. This durability ensures long-lasting performance, even in the most demanding applications.

3. **Scalability and Flexibility**: The modular design of the BENTLY Nevada allows for easy scalability. Whether you have a single machine or an extensive fleet of equipment, the system can be customized to meet your specific monitoring needs.

4. **Seamless Integration**: As part of the BENTLY automation products line, the Nevada can easily integrate with existing control systems and other BENTLY models, providing a comprehensive solution for machinery protection and monitoring.

5. **User-Friendly Interface**: The BENTLY Nevada features an intuitive interface that simplifies configuration and operation. Users can quickly access critical data and make adjustments with minimal training, enhancing overall productivity.

Usage Scenarios

The BENTLY Nevada is versatile and can be applied across various industries and applications, including:

1. **Power Generation**: In power plants, the BENTLY Nevada monitors turbines and generators, ensuring optimal performance and safeguarding against failures that could lead to costly outages.

2. **Oil and Gas**: In the oil and gas sector, this model is crucial for monitoring pumps, compressors, and turbines, helping to prevent catastrophic failures and environmental incidents.

3. **Mining**: The rugged design of the BENTLY Nevada makes it ideal for the mining industry, where equipment operates in

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.