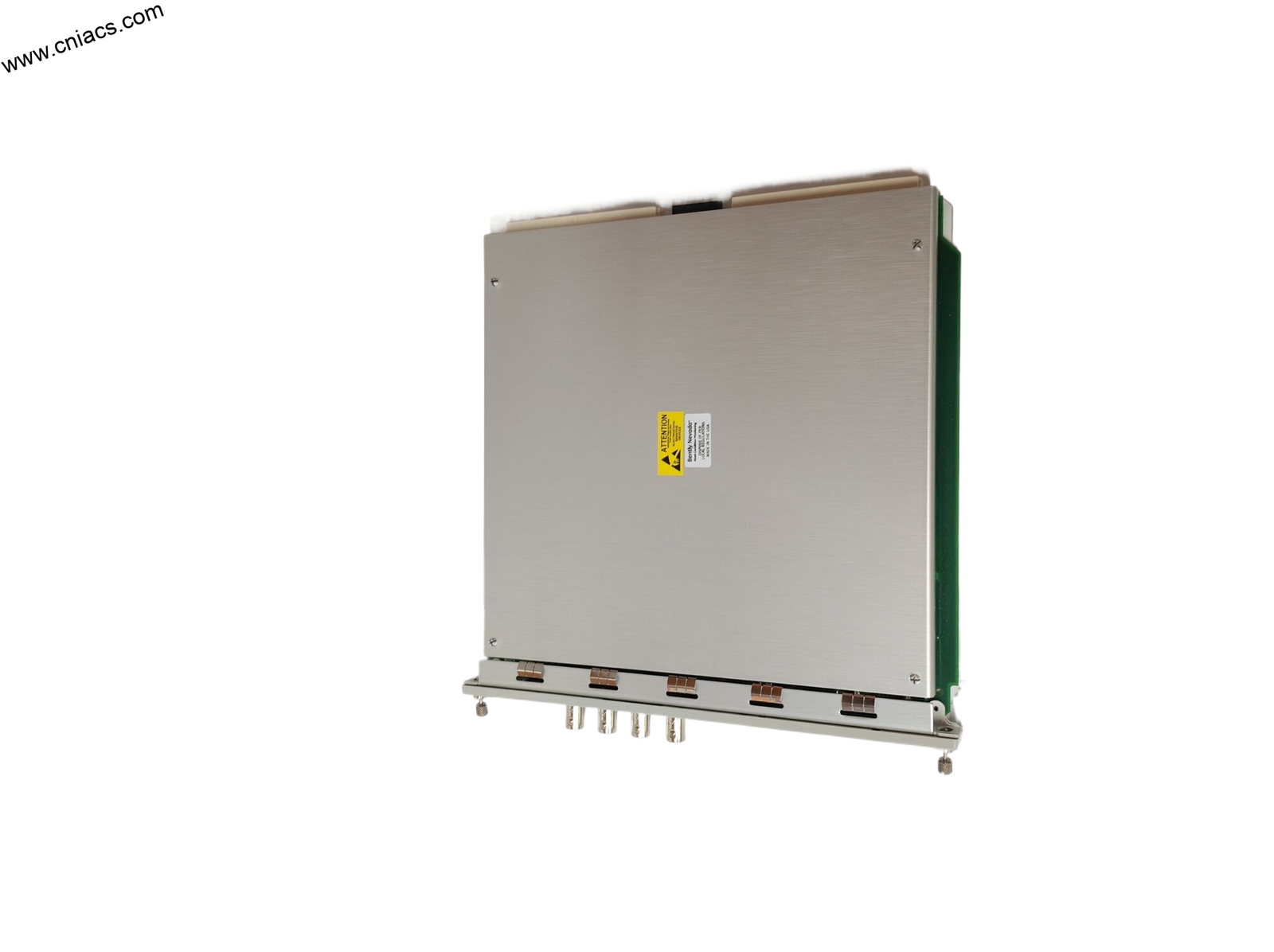

BENTLY Bently Nevada 330180-080-00-00 Advanced Proximity Sensor for Industrial Control Solutions

Introducing the BENTLY Bently Nevada 330180-080-00-00: the pinnacle of reliability and precision in vibration monitoring and machinery protection. Designed for engineers and technicians who demand the very best, the BENTLY Nevada 330180-080-00-00 offers advanced features that enhance your operational efficiency and asset longevity.

**Key Technical Features**

The BENTLY Nevada 330180-080-00-00 is a state-of-the-art vibration sensor that provides unparalleled accuracy in monitoring machine health. This model features high sensitivity and a broad frequency response, enabling it to detect even the smallest shifts in machinery performance. Key technical features include:

1. **High-Frequency Range**: Capable of monitoring a wide range of frequencies, this sensor ensures that it captures critical vibration data across various equipment types.

2. **Robust Design**: Built to withstand harsh industrial environments, the BENTLY Nevada 330180-080-00-00 is resistant to dust, moisture, and extreme temperatures, ensuring reliability in demanding applications.

3. **Compatibility with BENTLY Systems**: This model seamlessly integrates with other BENTLY automation products, allowing for a comprehensive monitoring solution that is easy to implement and manage.

4. **Real-Time Data Monitoring**: The ability to provide real-time data allows for immediate responses to any anomalies detected, significantly reducing the risk of unexpected downtime.

5. **User-Friendly Interface**: An intuitive display and easy-to-navigate controls make it accessible for technicians of all skill levels.

**Usage Scenarios**

The versatility of the BENTLY Nevada 330180-080-00-00 makes it an ideal choice for various industries. Whether you are in oil and gas, power generation, or manufacturing, this sensor enhances operational reliability. Common usage scenarios include:

– **Rotating Equipment Monitoring**: This model excels in monitoring rotating machinery, including pumps, turbines, and compressors, ensuring optimal performance and early detection of potential failures.

– **Predictive Maintenance**: By providing valuable insights into machine health, the BENTLY Nevada 330180-080-00-00 supports predictive maintenance initiatives that can save companies significant costs associated with unplanned maintenance and equipment failure.

– **Condition Monitoring**: Industries can leverage this product to implement comprehensive condition monitoring programs, allowing for systematic evaluations of equipment performance and health over time.

**Comparison with Other Models**

When compared to other models in the BENTLY lineup, the BENTLY Nevada

The above parameters are for reference only. Please contact our technical team for precise selection.

**Key Technical Features**

The BENTLY Nevada 330180-080-00-00 is a state-of-the-art vibration sensor that provides unparalleled accuracy in monitoring machine health. This model features high sensitivity and a broad frequency response, enabling it to detect even the smallest shifts in machinery performance. Key technical features include:

1. **High-Frequency Range**: Capable of monitoring a wide range of frequencies, this sensor ensures that it captures critical vibration data across various equipment types.

2. **Robust Design**: Built to withstand harsh industrial environments, the BENTLY Nevada 330180-080-00-00 is resistant to dust, moisture, and extreme temperatures, ensuring reliability in demanding applications.

3. **Compatibility with BENTLY Systems**: This model seamlessly integrates with other BENTLY automation products, allowing for a comprehensive monitoring solution that is easy to implement and manage.

4. **Real-Time Data Monitoring**: The ability to provide real-time data allows for immediate responses to any anomalies detected, significantly reducing the risk of unexpected downtime.

5. **User-Friendly Interface**: An intuitive display and easy-to-navigate controls make it accessible for technicians of all skill levels.

**Usage Scenarios**

The versatility of the BENTLY Nevada 330180-080-00-00 makes it an ideal choice for various industries. Whether you are in oil and gas, power generation, or manufacturing, this sensor enhances operational reliability. Common usage scenarios include:

– **Rotating Equipment Monitoring**: This model excels in monitoring rotating machinery, including pumps, turbines, and compressors, ensuring optimal performance and early detection of potential failures.

– **Predictive Maintenance**: By providing valuable insights into machine health, the BENTLY Nevada 330180-080-00-00 supports predictive maintenance initiatives that can save companies significant costs associated with unplanned maintenance and equipment failure.

– **Condition Monitoring**: Industries can leverage this product to implement comprehensive condition monitoring programs, allowing for systematic evaluations of equipment performance and health over time.

**Comparison with Other Models**

When compared to other models in the BENTLY lineup, the BENTLY Nevada

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.png?v=1739321142)

-300x300.jpg?v=1739320885)

There are no reviews yet.