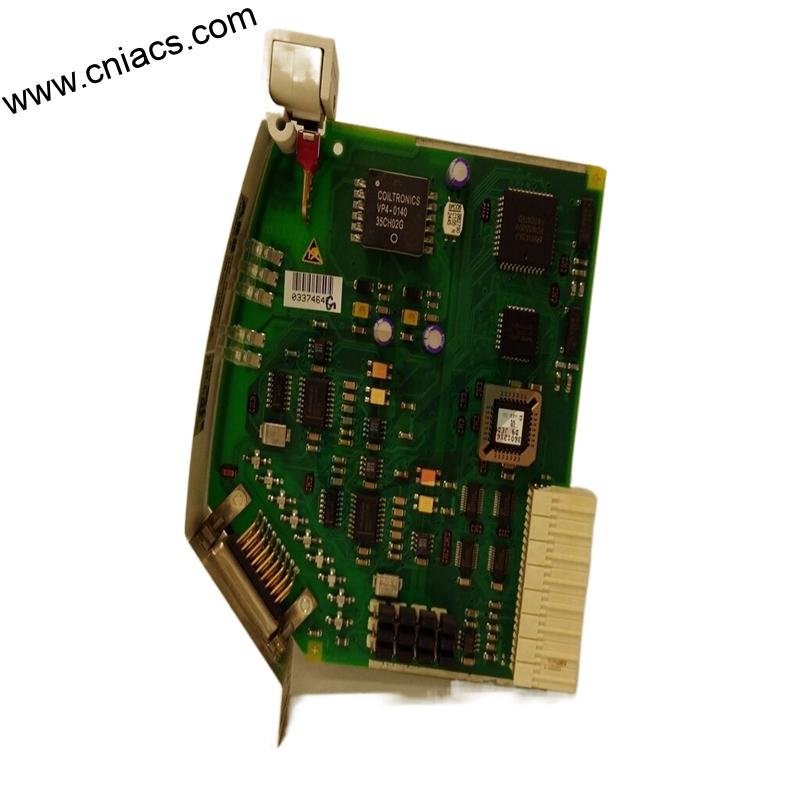

ABB DSQC 102 PC BOARD: Precision Control, Industrial Automation Excellence

Introducing the ABB DSQC 102: a pivotal component in the realm of industrial automation that exemplifies ABB's commitment to innovation, reliability, and performance. Designed for robust automation applications, the ABB DSQC 102 is engineered to meet the demanding requirements of modern manufacturing environments, ensuring seamless integration and enhanced productivity.

**Key Technical Features**

The ABB DSQC 102 is distinguished by its advanced technical specifications that cater to a wide range of automation needs. Featuring a highly efficient processor, it offers rapid data processing capabilities that ensure real-time decision-making and control. The unit supports a variety of communication protocols, making it compatible with other ABB automation products, such as the ABB UNS1860B-P and the ABB TU852 S800 I/O, facilitating easy integration into existing systems.

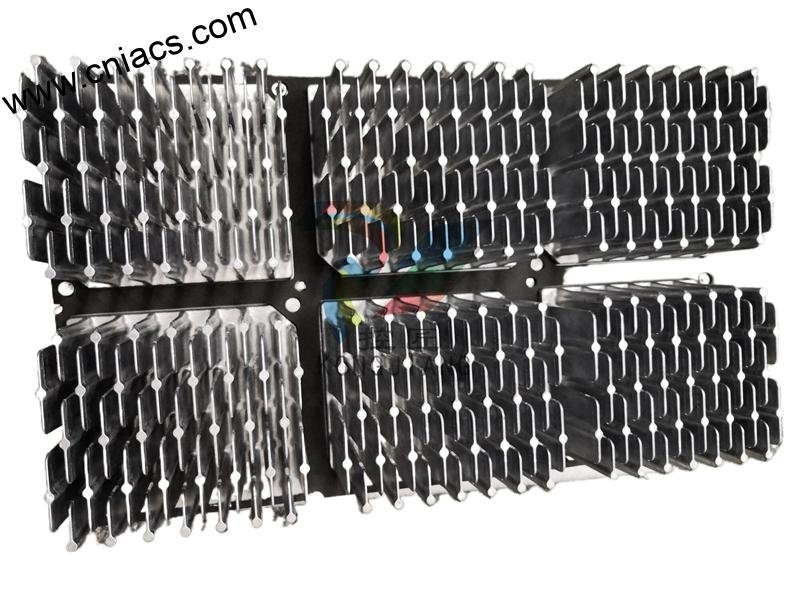

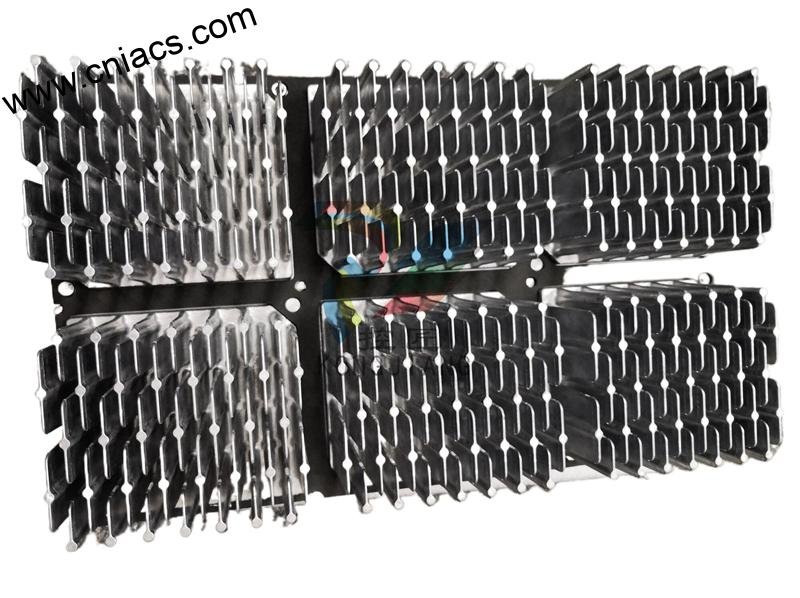

The device boasts a compact design, which allows for easy installation in tight spaces without compromising on performance. The ABB DSQC 102 is equipped with multiple I/O channels, enabling it to connect with various sensors and actuators, thereby providing flexibility in configuration. Its high degree of reliability is underscored by its rugged construction, which is designed to withstand the rigors of industrial environments, including extreme temperatures and vibrations.

Moreover, the ABB DSQC 102 features enhanced diagnostic capabilities that enable users to monitor system performance in real time. This allows for proactive maintenance and troubleshooting, significantly reducing downtime and operational costs. The unit is also compatible with ABB's extensive software suite, including programming and simulation tools, which enhances its usability and functionality.

**Usage Scenarios**

The ABB DSQC 102 is ideally suited for a myriad of applications across various sectors, including manufacturing, robotics, and process automation. In automotive production lines, for instance, it can be utilized to control robotic arms, ensuring precise movements and coordination during assembly processes. Its ability to process data in real-time makes it invaluable in high-speed environments where quick decision-making is crucial.

In packaging applications, the ABB DSQC 102 can be employed to synchronize conveyor systems, manage machine operations, and optimize workflow. Its versatility extends to food and beverage processing, where it can facilitate the automation of bottling and labeling operations, ensuring compliance with stringent industry standards.

In the context of energy management, the ABB DSQC 102 can be integrated into smart grid systems to monitor and control energy consumption, contributing to increased efficiency and sustainability. With its wide-ranging capabilities, this product serves as a cornerstone for businesses looking to enhance their automation capabilities and drive operational excellence.

**Comparison with Other Models**

When comparing the ABB DSQC 102 with other models within the ABB portfolio, such as the ABB DSQC352B or the PM511V16 3BSE011181R1, several distinctions emerge. While the DSQC 102 is renowned for its compactness and high-speed processing, the DSQC352B offers additional multi-axis motion control features that may be more suited for complex robotic applications.

In contrast, models like the ABB 07DC91 and the PM864AK01 are tailored for specific industrial needs, such as process control and advanced motion management. While they excel in their respective niches, the ABB DSQC 102 stands out for its versatility, making it a preferred choice for users seeking a multi-functional solution that can adapt to various automation scenarios.

Another notable comparison can be made with the ABB IRB 2600, a robotic arm that works in conjunction with the DSQC 102. While the IRB 2600 is engineered for precision and flexibility in tasks such as welding and material handling, the DSQC 102 plays a critical role in ensuring that the robotic arm operates seamlessly within the broader automation framework.

**Related Models**

The ABB DSQC 102 is part of an extensive lineup of ABB automation products that cater to diverse industrial needs. Some related models that complement the DSQC 102 include:

1. **ABB UNS1860B-P** – A versatile controller known for its robustness and reliability in automation tasks.

2. **ABB TU852 S800 I/O** – A modular I/O system that enhances the DSQC 102's capabilities by providing additional input and output options.

3. **ABB PM511V16 3BSE011181R1** – A signal processing module that works in tandem with the DSQC 102 for advanced control applications.

4. **ABB YPP110A** – A power supply designed to ensure uninterrupted operation of the DSQC 102 and other connected devices.

5. **ABB SC540** – A safety controller that integrates with the DSQC 102 for enhanced operational safety in automated environments.

6. **ABB ACS880-01-246A-3** – A variable frequency drive that provides precise motor control, complementing the capabilities of the DSQC 102.

7. **ABB SDCS-PIN-51** – A powerful control unit that allows for advanced motion control applications alongside the DSQC 102.

8. **ABB 3HAC16035-1** – A communication module that enables seamless interaction between the DSQC 102 and other automation systems.

9. **ABB DC551-CS31** – A control system that provides additional functionality and compatibility with the DSQC 102.

10. **ABB IRB 2400/1403/CR3** – A versatile industrial robot that, when paired with the DSQC 102, offers a powerful automation solution for various manufacturing tasks.

In conclusion, the ABB DSQC 102 stands as a testament to ABB's innovation in automation technology. Whether you are looking to enhance operational efficiency, improve system integration, or streamline your production processes, the ABB DSQC 102 is the ideal solution for your automation needs. With its advanced features and flexibility, it reinforces ABB's position as a leader in providing cutting-edge automation products that drive industrial success.

The above parameters are for reference only. Please contact our technical team for precise selection.

**Key Technical Features**

The ABB DSQC 102 is distinguished by its advanced technical specifications that cater to a wide range of automation needs. Featuring a highly efficient processor, it offers rapid data processing capabilities that ensure real-time decision-making and control. The unit supports a variety of communication protocols, making it compatible with other ABB automation products, such as the ABB UNS1860B-P and the ABB TU852 S800 I/O, facilitating easy integration into existing systems.

The device boasts a compact design, which allows for easy installation in tight spaces without compromising on performance. The ABB DSQC 102 is equipped with multiple I/O channels, enabling it to connect with various sensors and actuators, thereby providing flexibility in configuration. Its high degree of reliability is underscored by its rugged construction, which is designed to withstand the rigors of industrial environments, including extreme temperatures and vibrations.

Moreover, the ABB DSQC 102 features enhanced diagnostic capabilities that enable users to monitor system performance in real time. This allows for proactive maintenance and troubleshooting, significantly reducing downtime and operational costs. The unit is also compatible with ABB's extensive software suite, including programming and simulation tools, which enhances its usability and functionality.

**Usage Scenarios**

The ABB DSQC 102 is ideally suited for a myriad of applications across various sectors, including manufacturing, robotics, and process automation. In automotive production lines, for instance, it can be utilized to control robotic arms, ensuring precise movements and coordination during assembly processes. Its ability to process data in real-time makes it invaluable in high-speed environments where quick decision-making is crucial.

In packaging applications, the ABB DSQC 102 can be employed to synchronize conveyor systems, manage machine operations, and optimize workflow. Its versatility extends to food and beverage processing, where it can facilitate the automation of bottling and labeling operations, ensuring compliance with stringent industry standards.

In the context of energy management, the ABB DSQC 102 can be integrated into smart grid systems to monitor and control energy consumption, contributing to increased efficiency and sustainability. With its wide-ranging capabilities, this product serves as a cornerstone for businesses looking to enhance their automation capabilities and drive operational excellence.

**Comparison with Other Models**

When comparing the ABB DSQC 102 with other models within the ABB portfolio, such as the ABB DSQC352B or the PM511V16 3BSE011181R1, several distinctions emerge. While the DSQC 102 is renowned for its compactness and high-speed processing, the DSQC352B offers additional multi-axis motion control features that may be more suited for complex robotic applications.

In contrast, models like the ABB 07DC91 and the PM864AK01 are tailored for specific industrial needs, such as process control and advanced motion management. While they excel in their respective niches, the ABB DSQC 102 stands out for its versatility, making it a preferred choice for users seeking a multi-functional solution that can adapt to various automation scenarios.

Another notable comparison can be made with the ABB IRB 2600, a robotic arm that works in conjunction with the DSQC 102. While the IRB 2600 is engineered for precision and flexibility in tasks such as welding and material handling, the DSQC 102 plays a critical role in ensuring that the robotic arm operates seamlessly within the broader automation framework.

**Related Models**

The ABB DSQC 102 is part of an extensive lineup of ABB automation products that cater to diverse industrial needs. Some related models that complement the DSQC 102 include:

1. **ABB UNS1860B-P** – A versatile controller known for its robustness and reliability in automation tasks.

2. **ABB TU852 S800 I/O** – A modular I/O system that enhances the DSQC 102's capabilities by providing additional input and output options.

3. **ABB PM511V16 3BSE011181R1** – A signal processing module that works in tandem with the DSQC 102 for advanced control applications.

4. **ABB YPP110A** – A power supply designed to ensure uninterrupted operation of the DSQC 102 and other connected devices.

5. **ABB SC540** – A safety controller that integrates with the DSQC 102 for enhanced operational safety in automated environments.

6. **ABB ACS880-01-246A-3** – A variable frequency drive that provides precise motor control, complementing the capabilities of the DSQC 102.

7. **ABB SDCS-PIN-51** – A powerful control unit that allows for advanced motion control applications alongside the DSQC 102.

8. **ABB 3HAC16035-1** – A communication module that enables seamless interaction between the DSQC 102 and other automation systems.

9. **ABB DC551-CS31** – A control system that provides additional functionality and compatibility with the DSQC 102.

10. **ABB IRB 2400/1403/CR3** – A versatile industrial robot that, when paired with the DSQC 102, offers a powerful automation solution for various manufacturing tasks.

In conclusion, the ABB DSQC 102 stands as a testament to ABB's innovation in automation technology. Whether you are looking to enhance operational efficiency, improve system integration, or streamline your production processes, the ABB DSQC 102 is the ideal solution for your automation needs. With its advanced features and flexibility, it reinforces ABB's position as a leader in providing cutting-edge automation products that drive industrial success.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.