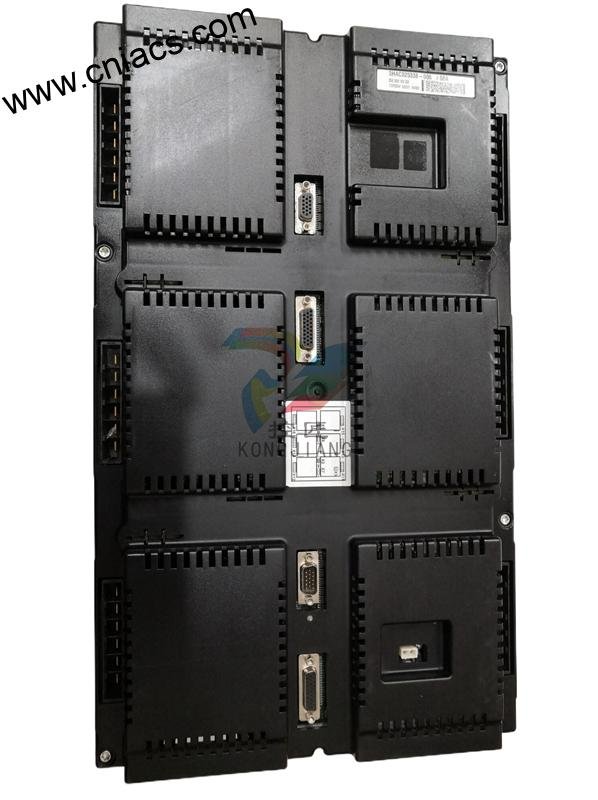

ABB IRB6700 3-4 Gripper Modules, 3HAC059479-001 & 3HAC059651-002 & 3HAC048233-001 nan

Introducing the ABB IRB6700 3-4 Gripper Modules (3HAC059479-001, 3HAC059651-002, 3HAC048233-001) – the pinnacle of robotic gripping technology designed to enhance productivity and efficiency in various industrial applications. With its robust features and versatility, this innovative solution is engineered to meet the demands of modern manufacturing environments, making it an essential addition to ABB's lineup of automation products.

Key Technical Features

The ABB IRB6700 3-4 Gripper Modules are equipped with cutting-edge technology that ensures reliable and precise operation. Key features include:

1. **High Payload Capacity**: The IRB6700 3-4 Gripper Modules offer a high payload capacity, allowing them to handle a variety of objects with ease. This makes them ideal for tasks that require the manipulation of heavy or bulky items, enhancing productivity and reducing cycle times.

2. **Robust Design**: Built with durability in mind, these gripper modules are constructed to withstand harsh industrial environments. Their robust design ensures longevity and reliability, minimizing downtime and maintenance costs.

3. **Advanced Control System**: The integrated control system allows for seamless communication between the gripper modules and ABB’s robotic arms, providing real-time feedback and improved control over the gripping process. This advanced feature enhances the precision and accuracy of operations.

4. **Flexible Configuration**: The modular design of the ABB IRB6700 Gripper Modules allows for flexible configuration, enabling users to customize their setup based on specific application requirements. This adaptability makes it suitable for a wide range of industries, from automotive to electronics manufacturing.

5. **Compatibility**: These gripper modules are designed to be fully compatible with other ABB robotics equipment, ensuring a smooth integration into existing systems. This compatibility enables users to leverage their current investments in ABB automation products while upgrading their capabilities.

Usage Scenarios

The ABB IRB6700 3-4 Gripper Modules are highly versatile and can be employed in various applications across multiple industries. Some common usage scenarios include:

– **Automotive Manufacturing**: In automotive plants, the ABB IRB6700 Gripper Modules can efficiently handle components such as engines, chassis parts, and electronic assemblies. Their high payload capacity and precision make them ideal for assembly lines where speed and accuracy are paramount.

– **Electronics Assembly**: In the electronics sector, these gripper modules can be utilized for assembling delicate components, ensuring that they are handled with care while maintaining high throughput. Their advanced control systems minimize the risk of damage during the gripping process.

– **Packaging and Palletizing**: The flexibility of the ABB IRB6700 Gripper Modules allows them to be effectively used in packaging and palletizing applications. They can handle various package sizes and weights, streamlining the end-of-line processes in manufacturing plants.

– **Warehouse Automation**: In distribution centers, these gripper modules can be employed in automated picking and sorting systems, enhancing the efficiency of order fulfillment processes. Their robust design allows them to operate seamlessly in fast-paced environments.

Comparison with Other Models

When comparing the ABB IRB6700 3-4 Gripper Modules with other models in the ABB lineup, it's clear that this series stands out for its balance of strength, precision, and versatility. While models like the ABB IRB 2400/1403/CR3 and ABB IRB 2600 are well-regarded for their general-purpose applications, the IRB6700 excels in scenarios requiring higher payloads and more advanced gripping capabilities.

In contrast to the ABB UNS1860B-P, which is designed for lightweight applications, the IRB6700’s robust construction and payload capacity make it suitable for heavier tasks. Additionally, compared to the ABB PM511V16 3BSE011181R1, which focuses on control and monitoring, the IRB6700 modules offer a wider range of physical handling capabilities.

Moreover, with advancements in technology, the IRB6700 modules are more adaptable than older models like the ABB 3HAC16035-1, providing users with a state-of-the-art solution designed to keep pace with the evolving landscape of automation.

Reference to Related Models

In addition to the ABB IRB6700 3-4 Gripper Modules, there are several related models that complement its functionality:

1. **ABB IRB 2400/1403/CR3**: Known for its versatility and reliability in various industrial applications.

2. **ABB IRB 2600**: A highly flexible robot designed for a range of tasks from welding to material handling.

3. **ABB UNS1860B-P**: A lighter model suited for less demanding applications.

4. **ABB PM511V16 3BSE011181R1**: Focused on control processes, providing robust monitoring capabilities.

5. **ABB 3HAC16035-1**: An older model that paved the way for advancements in robotic technology.

6. **ABB TU841 – 3BSE020848R1**: A terminal unit designed for interfacing with ABB automation products.

7. **ABB 3HAC027569-001**: A control module that enhances the capabilities of ABB robotic systems.

8. **ABB ACS880-01-246A-3 3ABD00035954-D**: A drive that integrates seamlessly with ABB robotics for optimized performance.

9. **ABB 3HNP04014-1**: A network processor that enhances communication between devices.

10. **ABB DSQC352B**: An I/O module that complements ABB robotics through improved data handling.

In conclusion, the ABB IRB6700 3-4 Gripper Modules (3HAC059479-001, 3HAC059651-002, 3HAC048233-001) represent a significant advancement in robotic gripping technology. Their high payload capacity, robust design, and advanced control systems make them an ideal choice for a wide range of applications in the manufacturing sector. When integrated with other ABB automation products, these modules can transform production lines, optimize workflows, and drive efficiencies across industries.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The ABB IRB6700 3-4 Gripper Modules are equipped with cutting-edge technology that ensures reliable and precise operation. Key features include:

1. **High Payload Capacity**: The IRB6700 3-4 Gripper Modules offer a high payload capacity, allowing them to handle a variety of objects with ease. This makes them ideal for tasks that require the manipulation of heavy or bulky items, enhancing productivity and reducing cycle times.

2. **Robust Design**: Built with durability in mind, these gripper modules are constructed to withstand harsh industrial environments. Their robust design ensures longevity and reliability, minimizing downtime and maintenance costs.

3. **Advanced Control System**: The integrated control system allows for seamless communication between the gripper modules and ABB’s robotic arms, providing real-time feedback and improved control over the gripping process. This advanced feature enhances the precision and accuracy of operations.

4. **Flexible Configuration**: The modular design of the ABB IRB6700 Gripper Modules allows for flexible configuration, enabling users to customize their setup based on specific application requirements. This adaptability makes it suitable for a wide range of industries, from automotive to electronics manufacturing.

5. **Compatibility**: These gripper modules are designed to be fully compatible with other ABB robotics equipment, ensuring a smooth integration into existing systems. This compatibility enables users to leverage their current investments in ABB automation products while upgrading their capabilities.

Usage Scenarios

The ABB IRB6700 3-4 Gripper Modules are highly versatile and can be employed in various applications across multiple industries. Some common usage scenarios include:

– **Automotive Manufacturing**: In automotive plants, the ABB IRB6700 Gripper Modules can efficiently handle components such as engines, chassis parts, and electronic assemblies. Their high payload capacity and precision make them ideal for assembly lines where speed and accuracy are paramount.

– **Electronics Assembly**: In the electronics sector, these gripper modules can be utilized for assembling delicate components, ensuring that they are handled with care while maintaining high throughput. Their advanced control systems minimize the risk of damage during the gripping process.

– **Packaging and Palletizing**: The flexibility of the ABB IRB6700 Gripper Modules allows them to be effectively used in packaging and palletizing applications. They can handle various package sizes and weights, streamlining the end-of-line processes in manufacturing plants.

– **Warehouse Automation**: In distribution centers, these gripper modules can be employed in automated picking and sorting systems, enhancing the efficiency of order fulfillment processes. Their robust design allows them to operate seamlessly in fast-paced environments.

Comparison with Other Models

When comparing the ABB IRB6700 3-4 Gripper Modules with other models in the ABB lineup, it's clear that this series stands out for its balance of strength, precision, and versatility. While models like the ABB IRB 2400/1403/CR3 and ABB IRB 2600 are well-regarded for their general-purpose applications, the IRB6700 excels in scenarios requiring higher payloads and more advanced gripping capabilities.

In contrast to the ABB UNS1860B-P, which is designed for lightweight applications, the IRB6700’s robust construction and payload capacity make it suitable for heavier tasks. Additionally, compared to the ABB PM511V16 3BSE011181R1, which focuses on control and monitoring, the IRB6700 modules offer a wider range of physical handling capabilities.

Moreover, with advancements in technology, the IRB6700 modules are more adaptable than older models like the ABB 3HAC16035-1, providing users with a state-of-the-art solution designed to keep pace with the evolving landscape of automation.

Reference to Related Models

In addition to the ABB IRB6700 3-4 Gripper Modules, there are several related models that complement its functionality:

1. **ABB IRB 2400/1403/CR3**: Known for its versatility and reliability in various industrial applications.

2. **ABB IRB 2600**: A highly flexible robot designed for a range of tasks from welding to material handling.

3. **ABB UNS1860B-P**: A lighter model suited for less demanding applications.

4. **ABB PM511V16 3BSE011181R1**: Focused on control processes, providing robust monitoring capabilities.

5. **ABB 3HAC16035-1**: An older model that paved the way for advancements in robotic technology.

6. **ABB TU841 – 3BSE020848R1**: A terminal unit designed for interfacing with ABB automation products.

7. **ABB 3HAC027569-001**: A control module that enhances the capabilities of ABB robotic systems.

8. **ABB ACS880-01-246A-3 3ABD00035954-D**: A drive that integrates seamlessly with ABB robotics for optimized performance.

9. **ABB 3HNP04014-1**: A network processor that enhances communication between devices.

10. **ABB DSQC352B**: An I/O module that complements ABB robotics through improved data handling.

In conclusion, the ABB IRB6700 3-4 Gripper Modules (3HAC059479-001, 3HAC059651-002, 3HAC048233-001) represent a significant advancement in robotic gripping technology. Their high payload capacity, robust design, and advanced control systems make them an ideal choice for a wide range of applications in the manufacturing sector. When integrated with other ABB automation products, these modules can transform production lines, optimize workflows, and drive efficiencies across industries.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.