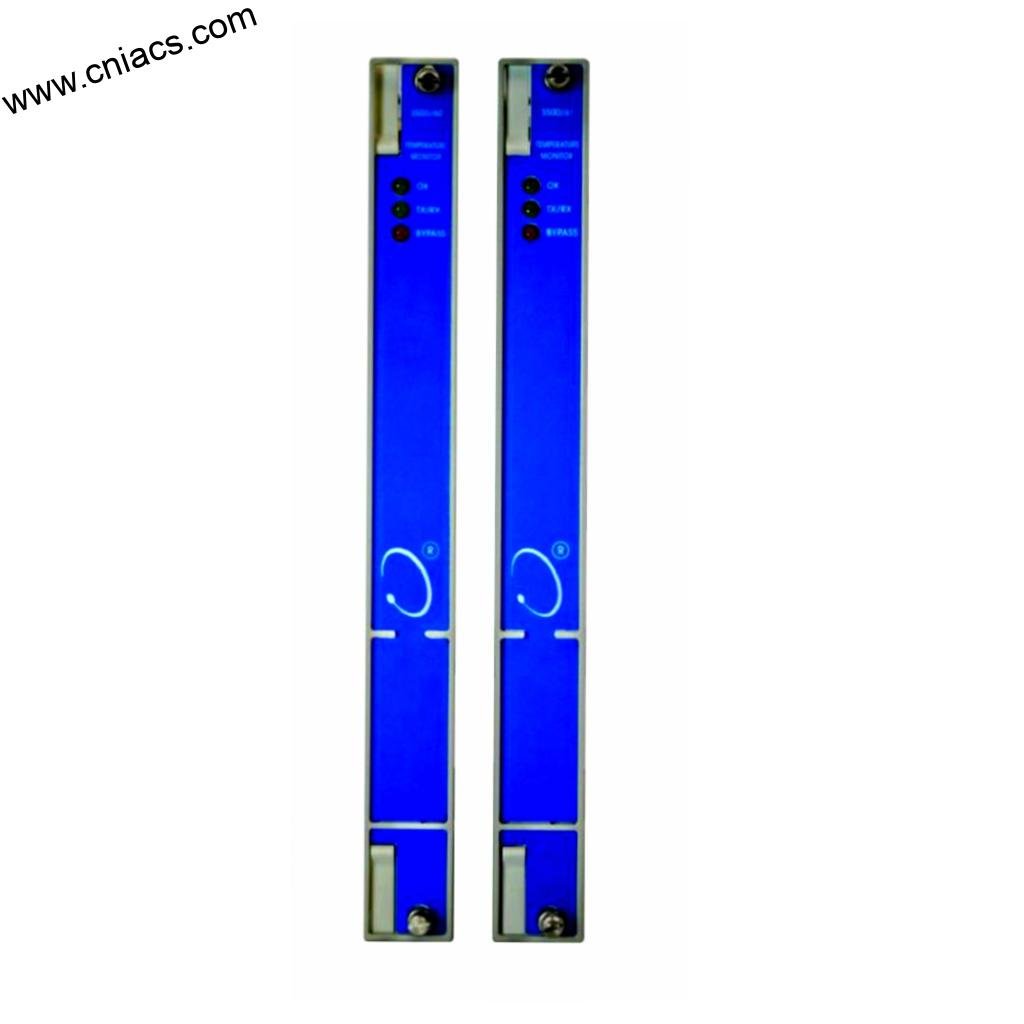

BENTLY 21000-16-10-00-065-04-02 Quick Delivery, Advanced Control Module

Introducing the BENTLY 21000-16-10-00-065-04-02, a cutting-edge addition to the BENTLY automation products lineup, designed for precision monitoring and control in industrial environments. This model stands out with its robust features, versatile usage scenarios, and a performance that makes it a preferred choice for professionals in various sectors.

Key Technical Features:

The BENTLY 21000-16-10-00-065-04-02 is engineered with advanced technology to ensure optimal performance. One of its standout features is its high-frequency data acquisition capability, which allows for real-time monitoring of critical parameters, ensuring that your systems operate within optimal thresholds. It boasts a durable design, capable of withstanding harsh industrial environments, including extreme temperatures and vibrations.

The device includes advanced communication protocols, ensuring seamless integration with existing systems. This feature is vital for industries that require interoperability among various devices and platforms. Additionally, the BENTLY 21000-16-10-00-065-04-02 supports extensive diagnostic functions, allowing users to troubleshoot issues before they escalate, thereby saving time and reducing maintenance costs.

Another highlight is its user-friendly interface, which simplifies operation and enhances user experience. The intuitive design facilitates quick navigation through various settings, making it accessible even for those who may not be highly technical. Furthermore, this model is equipped with customizable alerts and notifications, ensuring that users are promptly informed of any anomalies in their systems.

Usage Scenarios:

The BENTLY 21000-16-10-00-065-04-02 excels in a variety of industrial applications. In power generation facilities, it plays a crucial role in monitoring turbine performance, ensuring that these critical assets function efficiently and without risk of failure. Its high-speed data acquisition is essential for applications where timing is critical, such as in rotating machinery, where even a slight delay in monitoring can lead to catastrophic failures.

In the oil and gas sector, this model is invaluable for monitoring pipeline integrity and compressor performance. The ability to provide real-time data helps prevent leaks and ensures that operational efficiency is maintained. Similarly, in manufacturing environments, the BENTLY 21000-16-10-00-065-04-02 is instrumental in monitoring conveyor systems and other automated processes, ensuring that production lines remain uninterrupted and efficient.

Moreover, this model is suitable for aerospace and defense applications, where precision monitoring of equipment is non-negotiable. By integrating the BENTLY 21000-

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The BENTLY 21000-16-10-00-065-04-02 is engineered with advanced technology to ensure optimal performance. One of its standout features is its high-frequency data acquisition capability, which allows for real-time monitoring of critical parameters, ensuring that your systems operate within optimal thresholds. It boasts a durable design, capable of withstanding harsh industrial environments, including extreme temperatures and vibrations.

The device includes advanced communication protocols, ensuring seamless integration with existing systems. This feature is vital for industries that require interoperability among various devices and platforms. Additionally, the BENTLY 21000-16-10-00-065-04-02 supports extensive diagnostic functions, allowing users to troubleshoot issues before they escalate, thereby saving time and reducing maintenance costs.

Another highlight is its user-friendly interface, which simplifies operation and enhances user experience. The intuitive design facilitates quick navigation through various settings, making it accessible even for those who may not be highly technical. Furthermore, this model is equipped with customizable alerts and notifications, ensuring that users are promptly informed of any anomalies in their systems.

Usage Scenarios:

The BENTLY 21000-16-10-00-065-04-02 excels in a variety of industrial applications. In power generation facilities, it plays a crucial role in monitoring turbine performance, ensuring that these critical assets function efficiently and without risk of failure. Its high-speed data acquisition is essential for applications where timing is critical, such as in rotating machinery, where even a slight delay in monitoring can lead to catastrophic failures.

In the oil and gas sector, this model is invaluable for monitoring pipeline integrity and compressor performance. The ability to provide real-time data helps prevent leaks and ensures that operational efficiency is maintained. Similarly, in manufacturing environments, the BENTLY 21000-16-10-00-065-04-02 is instrumental in monitoring conveyor systems and other automated processes, ensuring that production lines remain uninterrupted and efficient.

Moreover, this model is suitable for aerospace and defense applications, where precision monitoring of equipment is non-negotiable. By integrating the BENTLY 21000-

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.