BENTLY 330103-08-13-10-02-05 Advanced Control Module for Industrial Applications

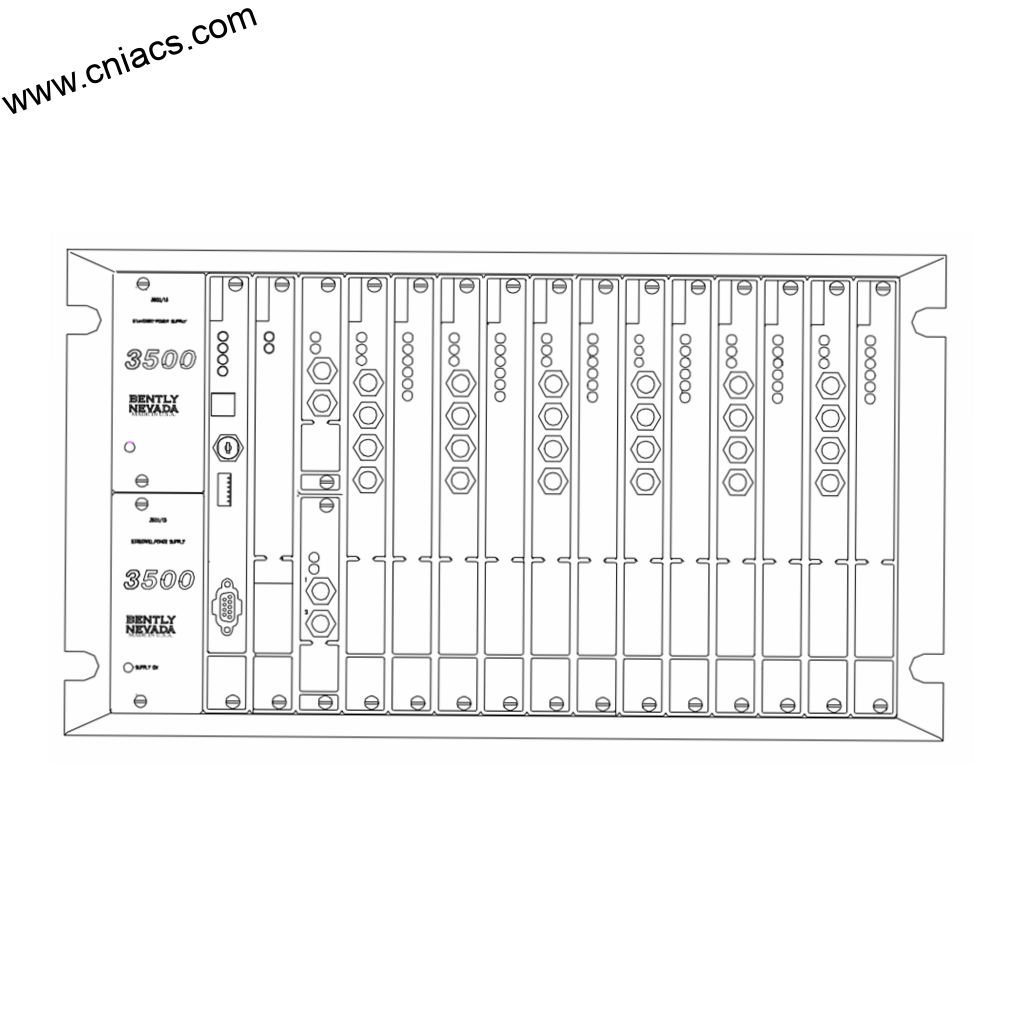

Introducing the BENTLY 330103-08-13-10-02-05 – a cutting-edge solution in the realm of condition monitoring and automation products. This model exemplifies BENTLY's commitment to delivering precision, reliability, and durability for industrial applications. With its robust design and advanced features, the BENTLY 330103-08-13-10-02-05 is crafted to meet the demands of modern industries, ensuring optimal performance and long-term operational efficiency.

Key Technical Features

The BENTLY 330103-08-13-10-02-05 is engineered with state-of-the-art technology that enhances its monitoring capabilities. One of its standout features is its ability to provide real-time data acquisition, allowing for continuous monitoring of critical parameters. This model supports various sensor inputs, enabling it to accommodate a wide range of applications. The BENTLY 330103-08-13-10-02-05 boasts high-speed processing capabilities, ensuring that data is captured and analyzed swiftly for timely decision-making.

Another significant feature is its exceptional fault detection and diagnostic abilities. The device utilizes advanced algorithms to identify anomalies and potential failures before they escalate into serious issues, thereby minimizing downtime and maintenance costs. The robustness of the BENTLY 330103-08-13-10-02-05 is further enhanced by its environmental resilience, making it suitable for operation in harsh industrial environments.

Additionally, this model is equipped with multiple communication protocols, including Ethernet and serial communication, which facilitate seamless integration with existing BENTLY automation products and third-party systems. With its intuitive interface, users can easily navigate through different settings and parameters, ensuring efficient operation and management.

Usage Scenarios

The BENTLY 330103-08-13-10-02-05 is versatile and can be used in various industrial settings. Its primary applications include monitoring rotating machinery, such as turbines, pumps, and compressors, in sectors like oil and gas, power generation, and manufacturing. By employing this model, organizations can significantly enhance their predictive maintenance strategies, leading to improved asset reliability and reduced operational risks.

In power plants, for instance, the BENTLY 330103-08-13-10-02-05 can monitor vibrations and temperature fluctuations in turbines, alerting operators to any irregularities that may indicate wear and tear or imminent failure. In the oil and gas sector, it can be used to track the health of pumps and compressors, ensuring that these critical components operate

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY 330103-08-13-10-02-05 is engineered with state-of-the-art technology that enhances its monitoring capabilities. One of its standout features is its ability to provide real-time data acquisition, allowing for continuous monitoring of critical parameters. This model supports various sensor inputs, enabling it to accommodate a wide range of applications. The BENTLY 330103-08-13-10-02-05 boasts high-speed processing capabilities, ensuring that data is captured and analyzed swiftly for timely decision-making.

Another significant feature is its exceptional fault detection and diagnostic abilities. The device utilizes advanced algorithms to identify anomalies and potential failures before they escalate into serious issues, thereby minimizing downtime and maintenance costs. The robustness of the BENTLY 330103-08-13-10-02-05 is further enhanced by its environmental resilience, making it suitable for operation in harsh industrial environments.

Additionally, this model is equipped with multiple communication protocols, including Ethernet and serial communication, which facilitate seamless integration with existing BENTLY automation products and third-party systems. With its intuitive interface, users can easily navigate through different settings and parameters, ensuring efficient operation and management.

Usage Scenarios

The BENTLY 330103-08-13-10-02-05 is versatile and can be used in various industrial settings. Its primary applications include monitoring rotating machinery, such as turbines, pumps, and compressors, in sectors like oil and gas, power generation, and manufacturing. By employing this model, organizations can significantly enhance their predictive maintenance strategies, leading to improved asset reliability and reduced operational risks.

In power plants, for instance, the BENTLY 330103-08-13-10-02-05 can monitor vibrations and temperature fluctuations in turbines, alerting operators to any irregularities that may indicate wear and tear or imminent failure. In the oil and gas sector, it can be used to track the health of pumps and compressors, ensuring that these critical components operate

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.