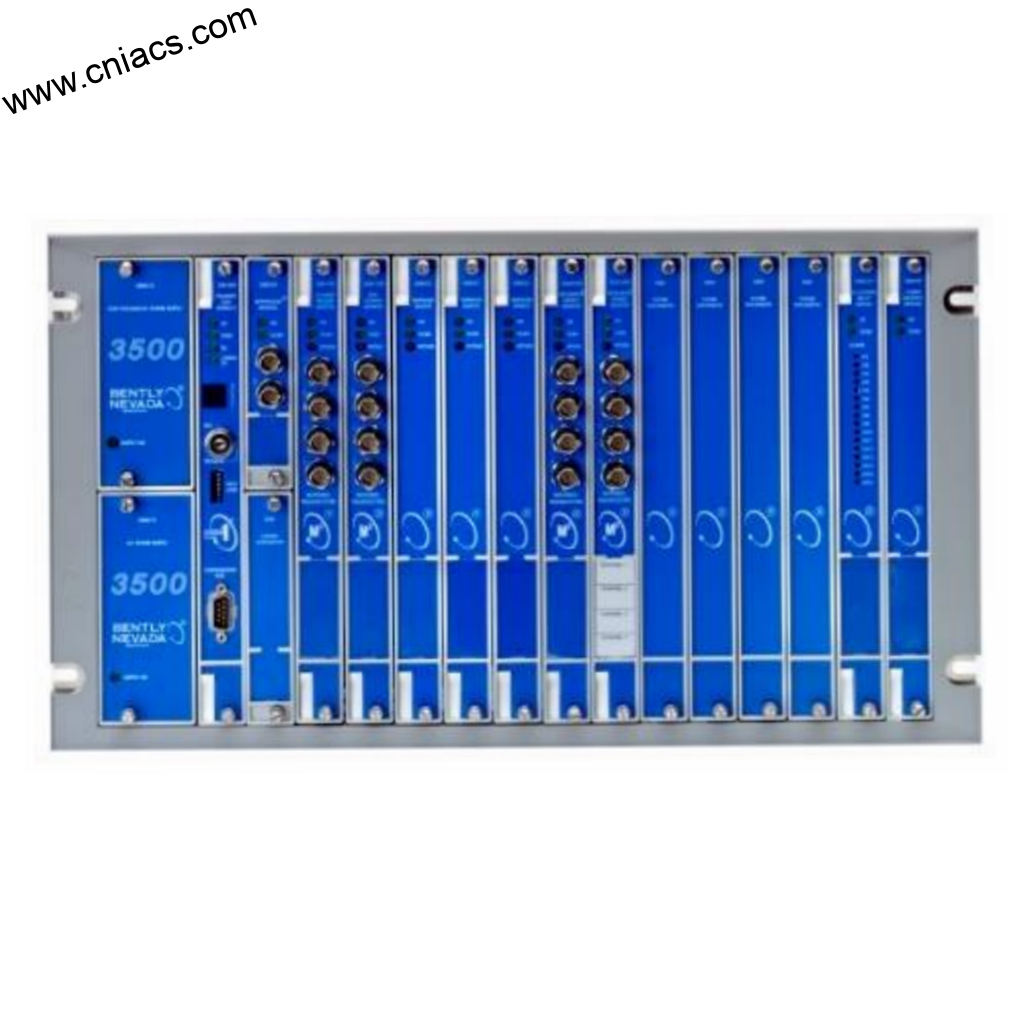

BENTLY 3500/15 127610-01 High Precision Vibration Monitoring Module

Introducing the BENTLY 3500/15 127610-01 – the pinnacle of performance and reliability in the world of industrial monitoring. This advanced machinery health monitoring system is designed to meet the rigorous demands of various industries, making it an essential component for any operation focused on optimizing performance and ensuring safety.

### Key Technical Features

The BENTLY 3500/15 127610-01 is equipped with cutting-edge technology that sets it apart from its competitors. Key features include:

– **High-Precision Monitoring**: The model provides real-time monitoring of machinery performance, enabling operators to detect anomalies before they lead to costly failures.

– **Versatile Input Channels**: It supports a variety of input types, allowing for the connection of multiple sensors, including vibration, temperature, and pressure, making it adaptable to various monitoring needs.

– **Advanced Signal Processing**: With sophisticated algorithms, the BENTLY 3500/15 can analyze data patterns effectively, providing insights into machine health and operational efficiency.

– **User-Friendly Interface**: The device features an intuitive interface that simplifies navigation and data interpretation, ensuring that operators can quickly access the information they need.

– **Robust Design**: Built to withstand harsh industrial environments, it features superior protection against dust, moisture, and temperature fluctuations, ensuring long-term reliability.

– **Scalability**: Its modular design allows for easy expansion, making it suitable for both small-scale and large-scale operations.

### Usage Scenarios

The BENTLY 3500/15 127610-01 is ideal for a variety of industries where machinery reliability is critical. Common usage scenarios include:

– **Manufacturing**: In production lines, this model can monitor equipment such as motors and pumps, helping to reduce downtime and enhance productivity.

– **Oil and Gas**: The BENTLY 3500/15 is perfect for monitoring pumps, compressors, and turbines in upstream and downstream operations, ensuring optimal performance and safety.

– **Power Generation**: It plays a crucial role in monitoring turbine and generator health, allowing for predictive maintenance that extends equipment life and reduces operational costs.

– **Water Treatment**: In municipal and industrial water treatment facilities, it ensures the reliable operation of pumps and mixers, crucial for maintaining water quality and compliance with regulations.

### Comparison with Other Models

When comparing the BENTLY 3500/15 127610-01 with other models in the BENTLY product line, such as the B

The above parameters are for reference only. Please contact our technical team for precise selection.

### Key Technical Features

The BENTLY 3500/15 127610-01 is equipped with cutting-edge technology that sets it apart from its competitors. Key features include:

– **High-Precision Monitoring**: The model provides real-time monitoring of machinery performance, enabling operators to detect anomalies before they lead to costly failures.

– **Versatile Input Channels**: It supports a variety of input types, allowing for the connection of multiple sensors, including vibration, temperature, and pressure, making it adaptable to various monitoring needs.

– **Advanced Signal Processing**: With sophisticated algorithms, the BENTLY 3500/15 can analyze data patterns effectively, providing insights into machine health and operational efficiency.

– **User-Friendly Interface**: The device features an intuitive interface that simplifies navigation and data interpretation, ensuring that operators can quickly access the information they need.

– **Robust Design**: Built to withstand harsh industrial environments, it features superior protection against dust, moisture, and temperature fluctuations, ensuring long-term reliability.

– **Scalability**: Its modular design allows for easy expansion, making it suitable for both small-scale and large-scale operations.

### Usage Scenarios

The BENTLY 3500/15 127610-01 is ideal for a variety of industries where machinery reliability is critical. Common usage scenarios include:

– **Manufacturing**: In production lines, this model can monitor equipment such as motors and pumps, helping to reduce downtime and enhance productivity.

– **Oil and Gas**: The BENTLY 3500/15 is perfect for monitoring pumps, compressors, and turbines in upstream and downstream operations, ensuring optimal performance and safety.

– **Power Generation**: It plays a crucial role in monitoring turbine and generator health, allowing for predictive maintenance that extends equipment life and reduces operational costs.

– **Water Treatment**: In municipal and industrial water treatment facilities, it ensures the reliable operation of pumps and mixers, crucial for maintaining water quality and compliance with regulations.

### Comparison with Other Models

When comparing the BENTLY 3500/15 127610-01 with other models in the BENTLY product line, such as the B

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.jpg?v=1739320885)

-300x300.png?v=1739321142)

There are no reviews yet.