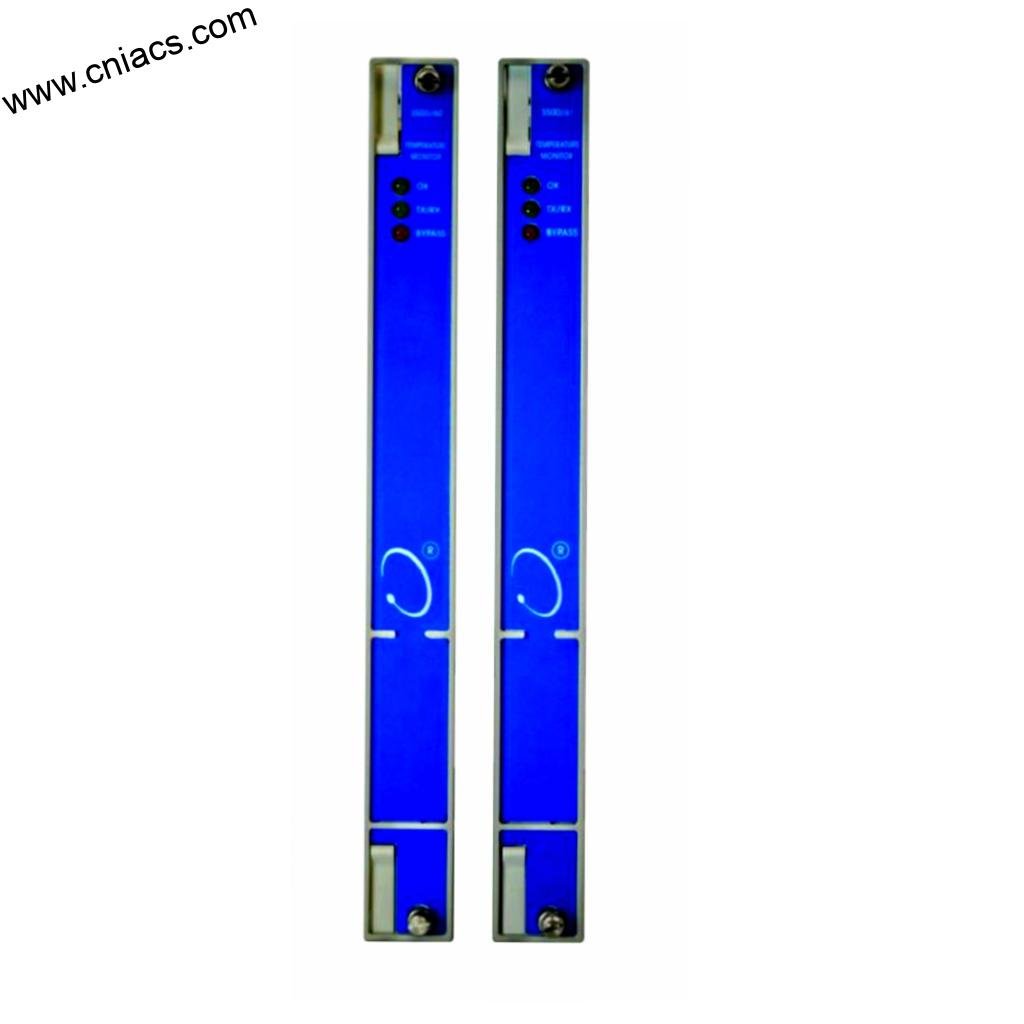

BENTLY 3500/25-01-00-00 3500 Series Vibration Monitoring System

Introducing the BENTLY 3500/25-01-00-00, a sophisticated and robust addition to the BENTLY automation products line, designed for the continuous monitoring and protection of critical machinery and equipment. This model is engineered to ensure the highest levels of reliability and performance in various industrial applications, making it an essential component in enhancing operational efficiency and safeguarding assets.

Key Technical Features

The BENTLY 3500/25-01-00-00 is equipped with an array of advanced features that set it apart in the realm of machinery monitoring. It offers real-time monitoring capabilities, providing users with critical data on vibration, temperature, and other essential parameters. The device features a high-precision measurement system that ensures accurate readings, enabling early detection of potential issues before they escalate into costly failures.

This model supports a wide range of input signals and can be seamlessly integrated into existing systems, allowing for greater flexibility in deployment. The BENTLY 3500/25-01-00-00 also boasts a user-friendly interface that simplifies setup and operation, reducing training time for personnel. Furthermore, the device is designed to withstand harsh environmental conditions, ensuring longevity and performance even in demanding industrial settings.

The BENTLY 3500/25-01-00-00 utilizes advanced algorithms for data analysis, which enhances the accuracy of predictive maintenance strategies. With its capability to store historical data, users can analyze trends over time, allowing for informed decision-making regarding maintenance schedules and operational adjustments.

Usage Scenarios

The versatility of the BENTLY 3500/25-01-00-00 makes it suitable for a wide range of applications across various industries. It is ideal for monitoring rotating equipment such as turbines, compressors, and pumps, where real-time data is crucial for maintaining efficiency and reliability. In the oil and gas sector, this model plays a pivotal role in ensuring the safe operation of critical machinery, helping to prevent unexpected downtime and costly repairs.

In power generation plants, the BENTLY 3500/25-01-00-00 is instrumental in monitoring the health of generators and auxiliary systems, ensuring that they operate within optimal parameters. The device is also valuable in manufacturing facilities, where it can be used to monitor conveyor systems and other machinery, reducing the risk of mechanical failures that can disrupt production.

Moreover, the BENTLY 3500/25-01-00-00 is an excellent choice for the mining and metals industry, where equipment reliability is paramount

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY 3500/25-01-00-00 is equipped with an array of advanced features that set it apart in the realm of machinery monitoring. It offers real-time monitoring capabilities, providing users with critical data on vibration, temperature, and other essential parameters. The device features a high-precision measurement system that ensures accurate readings, enabling early detection of potential issues before they escalate into costly failures.

This model supports a wide range of input signals and can be seamlessly integrated into existing systems, allowing for greater flexibility in deployment. The BENTLY 3500/25-01-00-00 also boasts a user-friendly interface that simplifies setup and operation, reducing training time for personnel. Furthermore, the device is designed to withstand harsh environmental conditions, ensuring longevity and performance even in demanding industrial settings.

The BENTLY 3500/25-01-00-00 utilizes advanced algorithms for data analysis, which enhances the accuracy of predictive maintenance strategies. With its capability to store historical data, users can analyze trends over time, allowing for informed decision-making regarding maintenance schedules and operational adjustments.

Usage Scenarios

The versatility of the BENTLY 3500/25-01-00-00 makes it suitable for a wide range of applications across various industries. It is ideal for monitoring rotating equipment such as turbines, compressors, and pumps, where real-time data is crucial for maintaining efficiency and reliability. In the oil and gas sector, this model plays a pivotal role in ensuring the safe operation of critical machinery, helping to prevent unexpected downtime and costly repairs.

In power generation plants, the BENTLY 3500/25-01-00-00 is instrumental in monitoring the health of generators and auxiliary systems, ensuring that they operate within optimal parameters. The device is also valuable in manufacturing facilities, where it can be used to monitor conveyor systems and other machinery, reducing the risk of mechanical failures that can disrupt production.

Moreover, the BENTLY 3500/25-01-00-00 is an excellent choice for the mining and metals industry, where equipment reliability is paramount

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.jpg?v=1739320885)

There are no reviews yet.