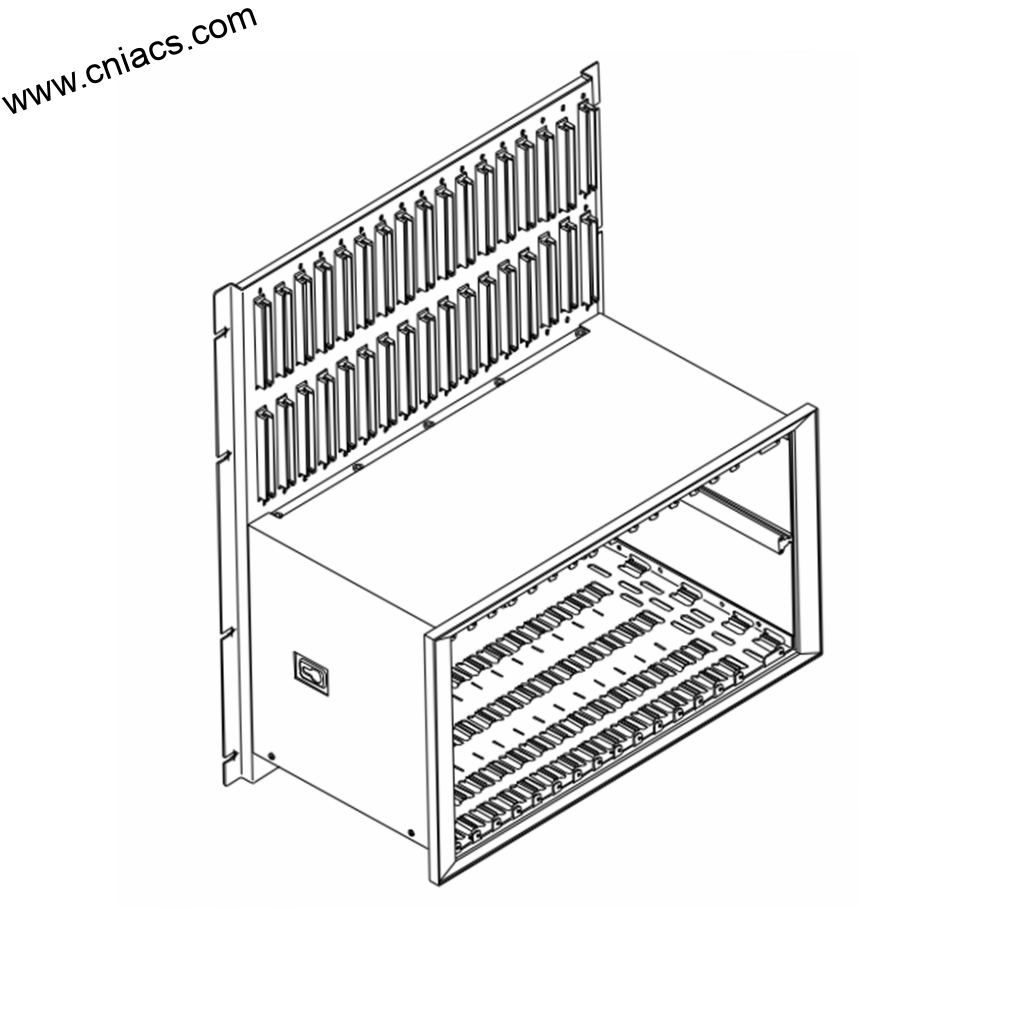

BENTLY 3500/32 125720-01 Small Card

Introducing the BENTLY 3500/32: the pinnacle of advanced monitoring technology. Designed to provide unparalleled reliability and precision, the BENTLY 3500/32 is engineered for the most demanding industrial environments. With its state-of-the-art features, it stands as a cornerstone of BENTLY automation products, ensuring optimal performance and enhanced operational efficiency.

Key Technical Features

The BENTLY 3500/32 is equipped with a multitude of cutting-edge features that make it a leader in the field of machinery protection and monitoring. Its advanced architecture allows for seamless integration into existing systems, making it the go-to choice for industries ranging from power generation to oil and gas.

1. **High-Performance Monitoring**: The BENTLY 3500/32 excels in vibration monitoring, offering high-resolution data that enables early fault detection. This capability helps to prevent unplanned downtime and extends the life of critical machinery.

2. **Versatile Input Options**: This model supports multiple input types, including proximity probes, accelerometers, and velocity sensors, allowing for flexible deployment across a wide range of applications.

3. **Robust Communication Protocols**: The BENTLY 3500/32 features integrated communication options, including Ethernet and serial interfaces, ensuring easy integration into modern automation systems.

4. **User-Friendly Interface**: The intuitive software interface allows for quick setup and easy interpretation of data, enabling operators to make informed decisions without extensive training.

5. **Scalability**: The modular design of the BENTLY 3500/32 allows for easy scalability, accommodating future expansion without a complete overhaul of existing systems.

Usage Scenarios

The BENTLY 3500/32 is perfect for a variety of applications across numerous industries. In the energy sector, it is essential for monitoring turbine health, providing real-time data that helps operators adjust parameters to optimize efficiency and prevent failures. In the oil and gas industry, its vibration monitoring capabilities are critical for protecting pumps and compressors, ensuring they operate within safe limits.

Moreover, the BENTLY 3500/32 is widely utilized in manufacturing environments, where it plays a vital role in monitoring the health of critical machinery, such as motors and gearboxes. By providing actionable insights, operators can perform predictive maintenance, thus minimizing operational costs and maximizing uptime.

Comparison with Other Models

When compared to other models in the BENTLY range, such as the BENTLY 3500/20 and BENTLY

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY 3500/32 is equipped with a multitude of cutting-edge features that make it a leader in the field of machinery protection and monitoring. Its advanced architecture allows for seamless integration into existing systems, making it the go-to choice for industries ranging from power generation to oil and gas.

1. **High-Performance Monitoring**: The BENTLY 3500/32 excels in vibration monitoring, offering high-resolution data that enables early fault detection. This capability helps to prevent unplanned downtime and extends the life of critical machinery.

2. **Versatile Input Options**: This model supports multiple input types, including proximity probes, accelerometers, and velocity sensors, allowing for flexible deployment across a wide range of applications.

3. **Robust Communication Protocols**: The BENTLY 3500/32 features integrated communication options, including Ethernet and serial interfaces, ensuring easy integration into modern automation systems.

4. **User-Friendly Interface**: The intuitive software interface allows for quick setup and easy interpretation of data, enabling operators to make informed decisions without extensive training.

5. **Scalability**: The modular design of the BENTLY 3500/32 allows for easy scalability, accommodating future expansion without a complete overhaul of existing systems.

Usage Scenarios

The BENTLY 3500/32 is perfect for a variety of applications across numerous industries. In the energy sector, it is essential for monitoring turbine health, providing real-time data that helps operators adjust parameters to optimize efficiency and prevent failures. In the oil and gas industry, its vibration monitoring capabilities are critical for protecting pumps and compressors, ensuring they operate within safe limits.

Moreover, the BENTLY 3500/32 is widely utilized in manufacturing environments, where it plays a vital role in monitoring the health of critical machinery, such as motors and gearboxes. By providing actionable insights, operators can perform predictive maintenance, thus minimizing operational costs and maximizing uptime.

Comparison with Other Models

When compared to other models in the BENTLY range, such as the BENTLY 3500/20 and BENTLY

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.png?v=1739321142)

There are no reviews yet.