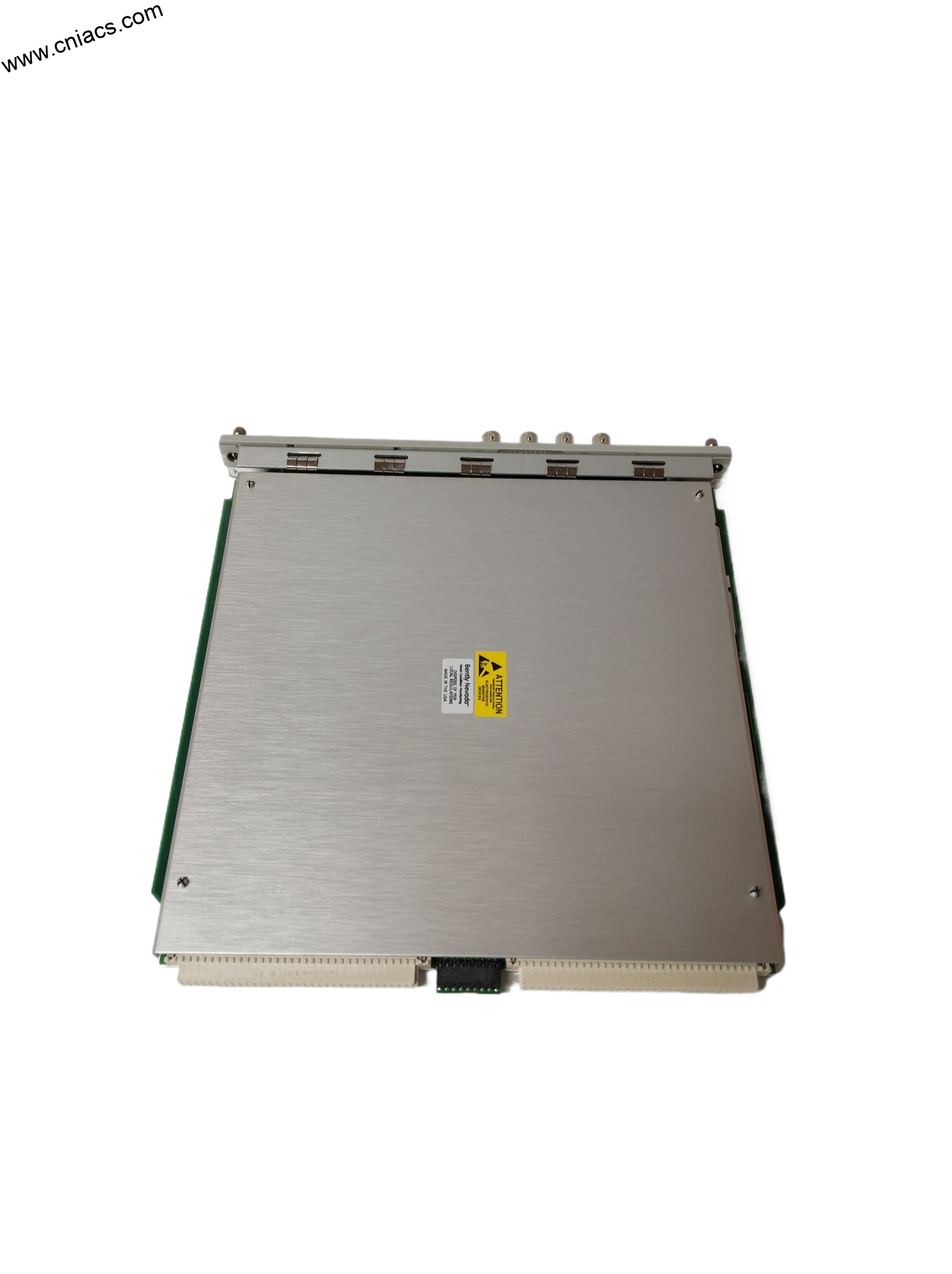

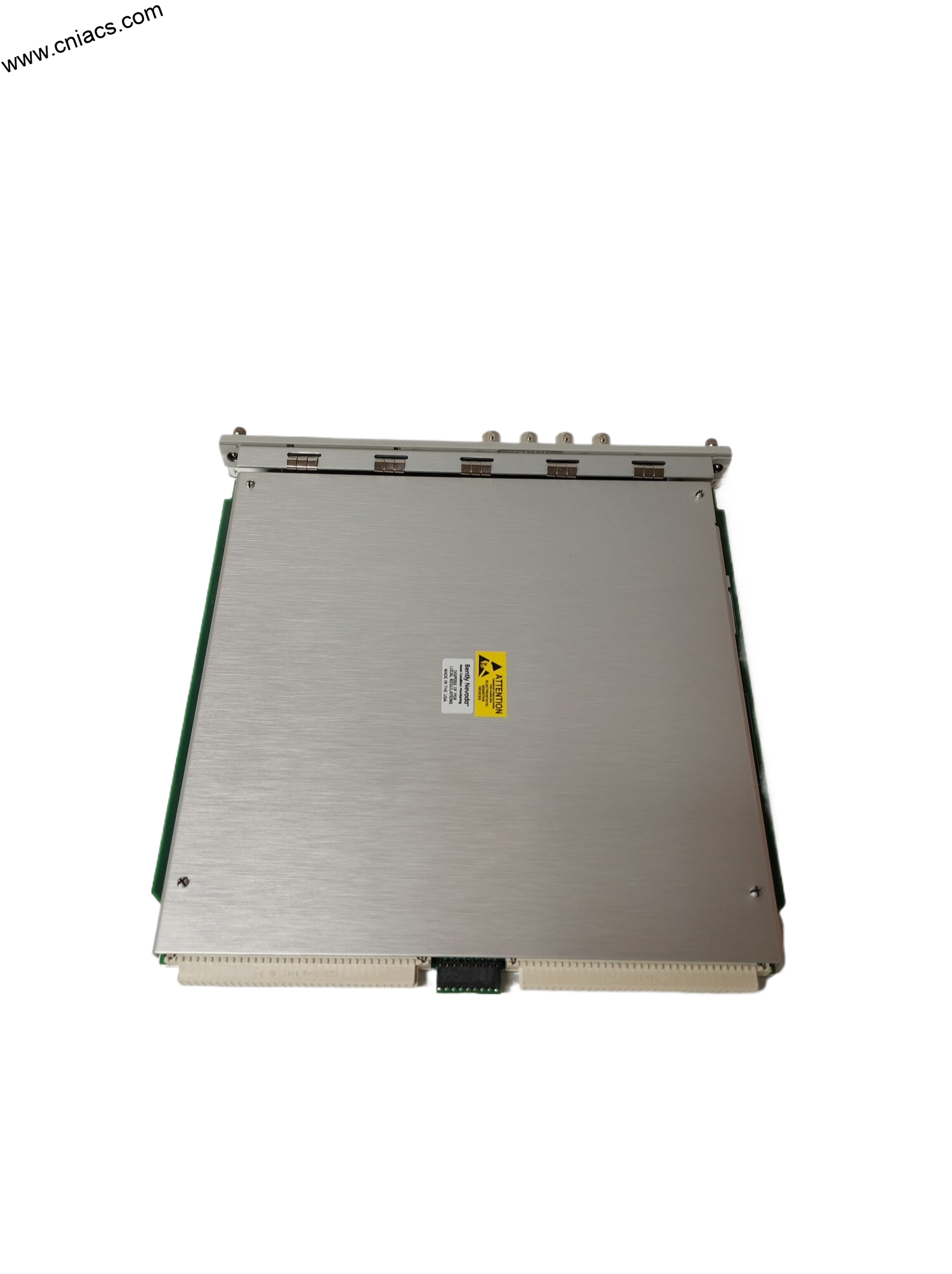

BENTLY 3500/62 Module for Advanced Industrial Control Systems

Introducing the BENTLY 3500/62, a cutting-edge solution in the realm of industrial automation and condition monitoring. This advanced device is designed to enhance the reliability and efficiency of your operations, making it an essential addition to your BENTLY automation products lineup. With a robust feature set, versatile applications, and superior performance, the BENTLY 3500/62 stands out as a leader in the industry.

Key Technical Features

The BENTLY 3500/62 is engineered to deliver exceptional performance in monitoring and protecting critical machinery. Its key technical features include:

1. **Advanced Vibration Monitoring**: The BENTLY 3500/62 utilizes state-of-the-art sensors to accurately measure vibration levels, enabling real-time detection of potential issues before they escalate into costly failures.

2. **Multi-Channel Capability**: This model supports multi-channel configurations, allowing for simultaneous monitoring of multiple machinery components. This feature is invaluable for complex systems where several machines are interconnected.

3. **High-Speed Data Acquisition**: With a high-speed data acquisition system, the BENTLY 3500/62 ensures that you receive timely and precise data for analysis, enabling informed decision-making regarding maintenance and operational adjustments.

4. **User-Friendly Interface**: The device is equipped with an intuitive interface that simplifies configuration and monitoring, making it accessible for both seasoned professionals and those new to condition monitoring technology.

5. **Robust Communication Protocols**: Featuring advanced communication capabilities, the BENTLY 3500/62 easily integrates with existing control systems, ensuring seamless data exchange and operational synergy.

6. **Scalability**: Designed to grow with your business, the BENTLY 3500/62 can be easily expanded or adapted to meet changing operational needs.

7. **Durability and Reliability**: Built to withstand challenging industrial environments, the BENTLY 3500/62 is constructed from high-quality materials that ensure longevity and reliability under various operating conditions.

Usage Scenarios

The versatility of the BENTLY 3500/62 makes it suitable for a wide range of applications across various industries. Here are a few scenarios where this model shines:

– **Oil and Gas**: In the oil and gas sector, the BENTLY 3500/62 can be used for monitoring rotating equipment, such as pumps and compressors, ensuring they operate within safe vibration limits and preventing unplanned downtime.

– **Manufacturing**: In manufacturing facilities, this model

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY 3500/62 is engineered to deliver exceptional performance in monitoring and protecting critical machinery. Its key technical features include:

1. **Advanced Vibration Monitoring**: The BENTLY 3500/62 utilizes state-of-the-art sensors to accurately measure vibration levels, enabling real-time detection of potential issues before they escalate into costly failures.

2. **Multi-Channel Capability**: This model supports multi-channel configurations, allowing for simultaneous monitoring of multiple machinery components. This feature is invaluable for complex systems where several machines are interconnected.

3. **High-Speed Data Acquisition**: With a high-speed data acquisition system, the BENTLY 3500/62 ensures that you receive timely and precise data for analysis, enabling informed decision-making regarding maintenance and operational adjustments.

4. **User-Friendly Interface**: The device is equipped with an intuitive interface that simplifies configuration and monitoring, making it accessible for both seasoned professionals and those new to condition monitoring technology.

5. **Robust Communication Protocols**: Featuring advanced communication capabilities, the BENTLY 3500/62 easily integrates with existing control systems, ensuring seamless data exchange and operational synergy.

6. **Scalability**: Designed to grow with your business, the BENTLY 3500/62 can be easily expanded or adapted to meet changing operational needs.

7. **Durability and Reliability**: Built to withstand challenging industrial environments, the BENTLY 3500/62 is constructed from high-quality materials that ensure longevity and reliability under various operating conditions.

Usage Scenarios

The versatility of the BENTLY 3500/62 makes it suitable for a wide range of applications across various industries. Here are a few scenarios where this model shines:

– **Oil and Gas**: In the oil and gas sector, the BENTLY 3500/62 can be used for monitoring rotating equipment, such as pumps and compressors, ensuring they operate within safe vibration limits and preventing unplanned downtime.

– **Manufacturing**: In manufacturing facilities, this model

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.