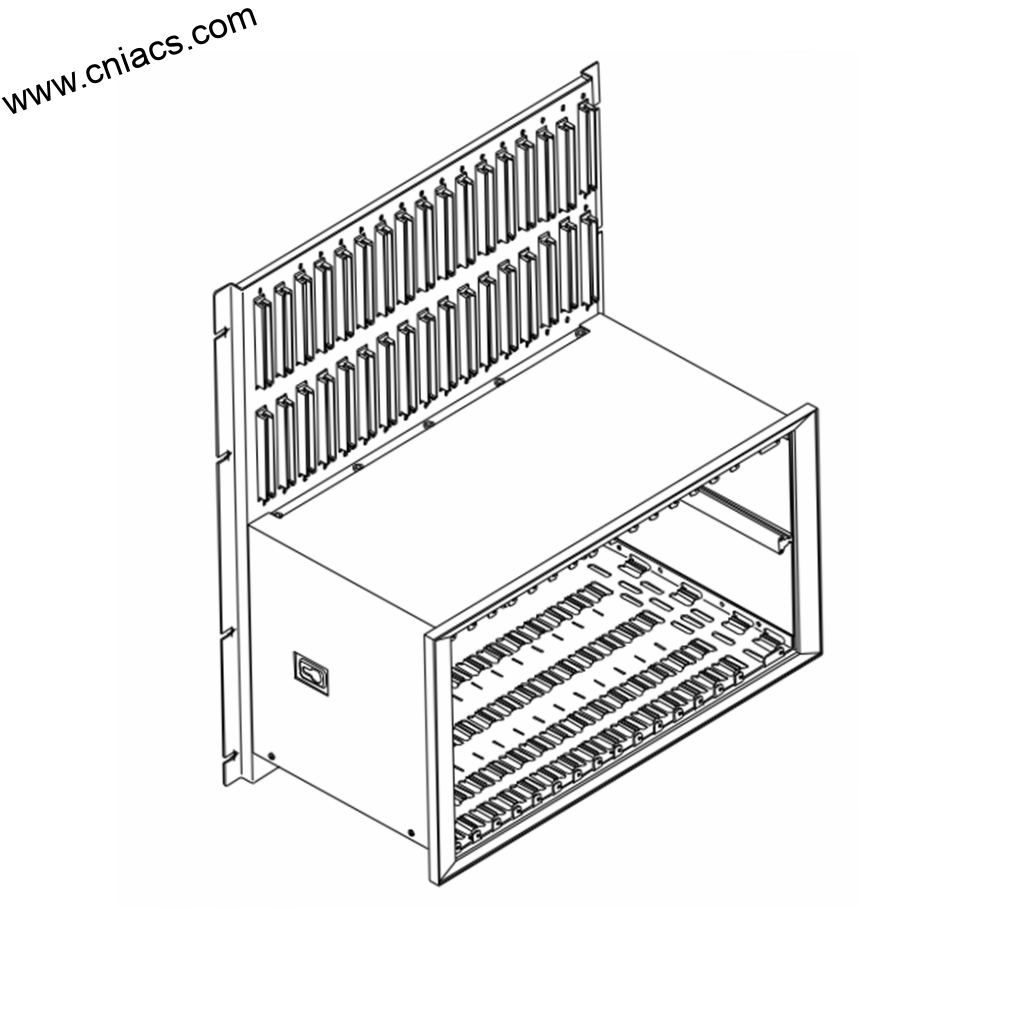

BENTLY Nevada 16710-20 Interconnect Cable, Industrial Control Systems, Field Instrument

Introducing the BENTLY Nevada: The Pinnacle of Condition Monitoring Solutions

When it comes to condition monitoring and machinery protection, the BENTLY Nevada series stands out as an industry leader. This robust and reliable system is engineered to deliver exceptional performance in the harshest environments, ensuring that your equipment operates smoothly and efficiently. Designed for seamless integration with BENTLY automation products, the BENTLY Nevada provides a comprehensive solution for monitoring the health of your machinery and preventing costly downtime.

Key Technical Features

The BENTLY Nevada is packed with advanced features designed to provide unparalleled accuracy and reliability. One of its standout specifications is its high-speed data acquisition capability, which allows for real-time monitoring of critical parameters such as vibration, temperature, and speed. The system supports both analog and digital inputs, making it adaptable to a wide range of sensors and configurations.

One of the key components of the BENTLY Nevada is its powerful signal processing capabilities. With advanced algorithms and filtering techniques, the system can distinguish between normal operational noise and potential fault indicators, providing users with actionable insights. The BENTLY Nevada also boasts a user-friendly interface, allowing operators to easily visualize data and trends, enhancing their ability to make informed decisions.

Furthermore, the BENTLY Nevada is built with durability in mind. Its rugged design ensures reliable performance in extreme temperatures, vibrations, and humidity, making it an ideal choice for industries such as oil and gas, power generation, and manufacturing. With modular architecture, the system can be easily expanded or customized to meet the specific needs of your operation.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for a wide array of applications. In the oil and gas industry, for instance, it is used to monitor pumps, compressors, and turbines, ensuring they operate within safe parameters. By detecting potential issues before they escalate into failures, the BENTLY Nevada helps companies minimize risks and reduce maintenance costs.

In power generation, the BENTLY Nevada is employed to safeguard critical assets such as generators and turbines. Its real-time monitoring capabilities allow operators to respond promptly to anomalies, preventing costly outages and ensuring consistent energy production.

Manufacturers also benefit from the BENTLY Nevada's advanced monitoring solutions. By implementing this system, businesses can enhance their production efficiency, reduce unplanned downtime, and optimize maintenance schedules, ultimately leading to increased profitability.

Comparison with Other Models

When comparing the BENTLY Nevada to other models within the BENTLY brand, such as the BENT

The above parameters are for reference only. Please contact our technical team for precise selection.

When it comes to condition monitoring and machinery protection, the BENTLY Nevada series stands out as an industry leader. This robust and reliable system is engineered to deliver exceptional performance in the harshest environments, ensuring that your equipment operates smoothly and efficiently. Designed for seamless integration with BENTLY automation products, the BENTLY Nevada provides a comprehensive solution for monitoring the health of your machinery and preventing costly downtime.

Key Technical Features

The BENTLY Nevada is packed with advanced features designed to provide unparalleled accuracy and reliability. One of its standout specifications is its high-speed data acquisition capability, which allows for real-time monitoring of critical parameters such as vibration, temperature, and speed. The system supports both analog and digital inputs, making it adaptable to a wide range of sensors and configurations.

One of the key components of the BENTLY Nevada is its powerful signal processing capabilities. With advanced algorithms and filtering techniques, the system can distinguish between normal operational noise and potential fault indicators, providing users with actionable insights. The BENTLY Nevada also boasts a user-friendly interface, allowing operators to easily visualize data and trends, enhancing their ability to make informed decisions.

Furthermore, the BENTLY Nevada is built with durability in mind. Its rugged design ensures reliable performance in extreme temperatures, vibrations, and humidity, making it an ideal choice for industries such as oil and gas, power generation, and manufacturing. With modular architecture, the system can be easily expanded or customized to meet the specific needs of your operation.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for a wide array of applications. In the oil and gas industry, for instance, it is used to monitor pumps, compressors, and turbines, ensuring they operate within safe parameters. By detecting potential issues before they escalate into failures, the BENTLY Nevada helps companies minimize risks and reduce maintenance costs.

In power generation, the BENTLY Nevada is employed to safeguard critical assets such as generators and turbines. Its real-time monitoring capabilities allow operators to respond promptly to anomalies, preventing costly outages and ensuring consistent energy production.

Manufacturers also benefit from the BENTLY Nevada's advanced monitoring solutions. By implementing this system, businesses can enhance their production efficiency, reduce unplanned downtime, and optimize maintenance schedules, ultimately leading to increased profitability.

Comparison with Other Models

When comparing the BENTLY Nevada to other models within the BENTLY brand, such as the BENT

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.png?v=1739321142)

There are no reviews yet.