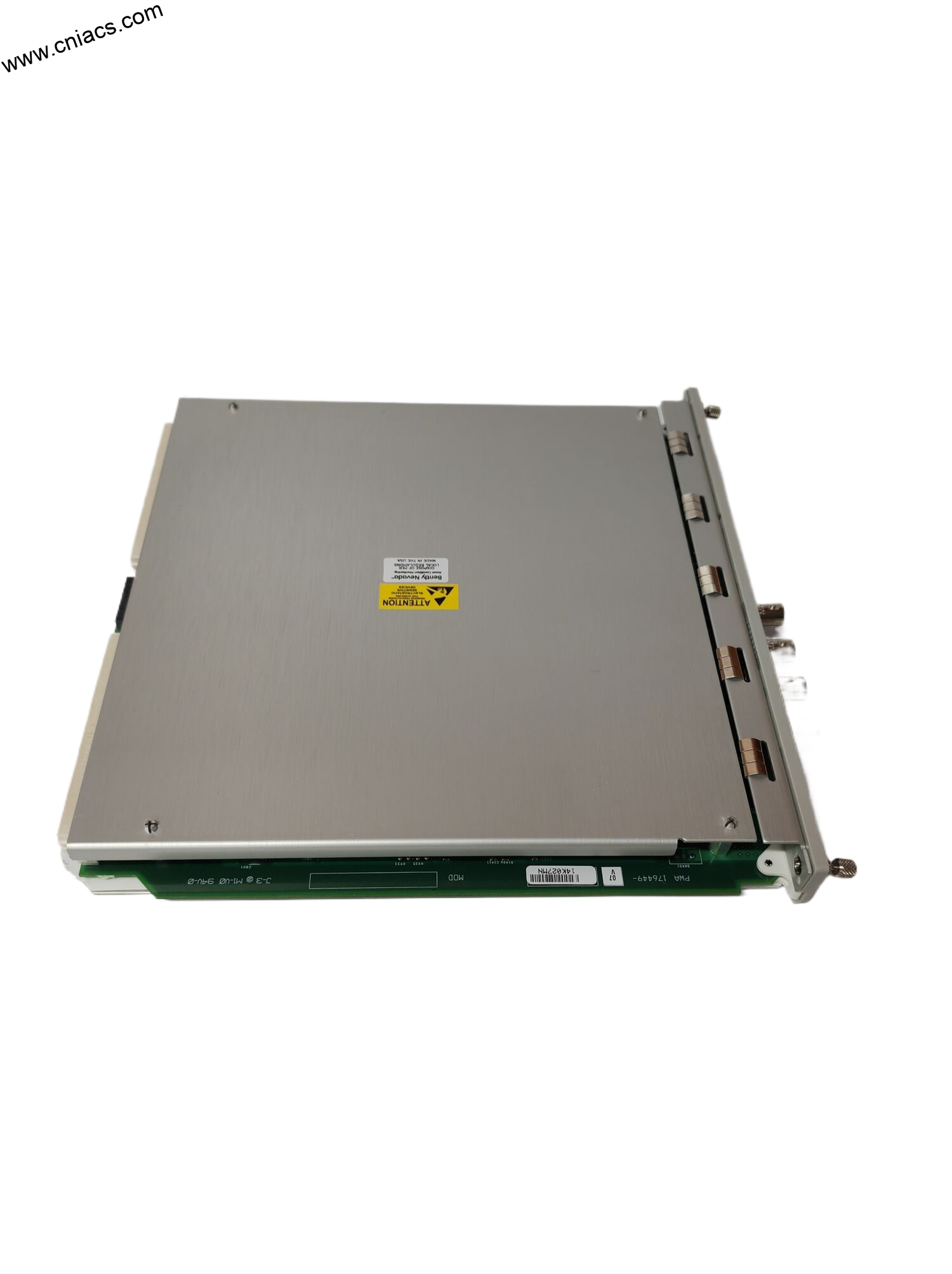

BENTLY Nevada 21747-040-00 4M Extension Cable, Precision Engineering for Industrial Control Systems

Introducing the BENTLY Nevada: The Pinnacle of Industrial Monitoring Solutions

In the world of industrial automation and monitoring, reliability and precision are paramount. The BENTLY Nevada model stands out as a leading solution, merging advanced technology with user-friendly functionality. Designed specifically for high-performance applications, the BENTLY Nevada offers a robust suite of features that empower companies to optimize their operations and safeguard their assets.

Key Technical Features

The BENTLY Nevada is equipped with cutting-edge technology that sets it apart from its competitors. At the heart of its functionality is its sophisticated vibration monitoring system, which utilizes high-fidelity sensors to capture minute changes in machinery performance. This capability allows for real-time monitoring of equipment health, enabling predictive maintenance and reducing unplanned downtime.

Key features include:

1. **Advanced Vibration Monitoring**: The BENTLY Nevada employs state-of-the-art accelerometers and vibration sensors to detect early signs of equipment failure.

2. **Comprehensive Data Analysis**: With its powerful data acquisition system, the model seamlessly integrates with existing plant infrastructures, providing detailed reports and analytics to inform decision-making.

3. **User-Centric Interface**: Designed with the end-user in mind, the BENTLY Nevada features an intuitive interface that allows operators to easily navigate through data and alerts.

4. **Scalability**: This model is built to grow with your operations, offering modular options that can be tailored to fit the specific needs of your facility.

5. **Robust Communication Protocols**: The BENTLY Nevada supports various communication standards, including Ethernet and Modbus, ensuring compatibility with a wide range of automation systems.

Usage Scenarios

The BENTLY Nevada is ideal for a diverse array of industrial applications, including:

– **Power Generation**: In power plants, maintaining optimal performance is crucial. The BENTLY Nevada monitors turbines and generators, helping to detect anomalies before they lead to costly outages.

– **Oil and Gas**: In the oil and gas sector, where equipment failure can result in significant losses, the BENTLY Nevada provides real-time insights into the health of pumps and compressors.

– **Manufacturing**: For manufacturing facilities, the model ensures that critical machinery operates smoothly, enhancing productivity and minimizing disruptions.

– **Water Treatment**: In water treatment plants, the BENTLY Nevada monitors pumps and motors, ensuring that systems function efficiently and safely.

Comparison with Other Models

When compared to other models within the BENTLY product range,

The above parameters are for reference only. Please contact our technical team for precise selection.

In the world of industrial automation and monitoring, reliability and precision are paramount. The BENTLY Nevada model stands out as a leading solution, merging advanced technology with user-friendly functionality. Designed specifically for high-performance applications, the BENTLY Nevada offers a robust suite of features that empower companies to optimize their operations and safeguard their assets.

Key Technical Features

The BENTLY Nevada is equipped with cutting-edge technology that sets it apart from its competitors. At the heart of its functionality is its sophisticated vibration monitoring system, which utilizes high-fidelity sensors to capture minute changes in machinery performance. This capability allows for real-time monitoring of equipment health, enabling predictive maintenance and reducing unplanned downtime.

Key features include:

1. **Advanced Vibration Monitoring**: The BENTLY Nevada employs state-of-the-art accelerometers and vibration sensors to detect early signs of equipment failure.

2. **Comprehensive Data Analysis**: With its powerful data acquisition system, the model seamlessly integrates with existing plant infrastructures, providing detailed reports and analytics to inform decision-making.

3. **User-Centric Interface**: Designed with the end-user in mind, the BENTLY Nevada features an intuitive interface that allows operators to easily navigate through data and alerts.

4. **Scalability**: This model is built to grow with your operations, offering modular options that can be tailored to fit the specific needs of your facility.

5. **Robust Communication Protocols**: The BENTLY Nevada supports various communication standards, including Ethernet and Modbus, ensuring compatibility with a wide range of automation systems.

Usage Scenarios

The BENTLY Nevada is ideal for a diverse array of industrial applications, including:

– **Power Generation**: In power plants, maintaining optimal performance is crucial. The BENTLY Nevada monitors turbines and generators, helping to detect anomalies before they lead to costly outages.

– **Oil and Gas**: In the oil and gas sector, where equipment failure can result in significant losses, the BENTLY Nevada provides real-time insights into the health of pumps and compressors.

– **Manufacturing**: For manufacturing facilities, the model ensures that critical machinery operates smoothly, enhancing productivity and minimizing disruptions.

– **Water Treatment**: In water treatment plants, the BENTLY Nevada monitors pumps and motors, ensuring that systems function efficiently and safely.

Comparison with Other Models

When compared to other models within the BENTLY product range,

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.