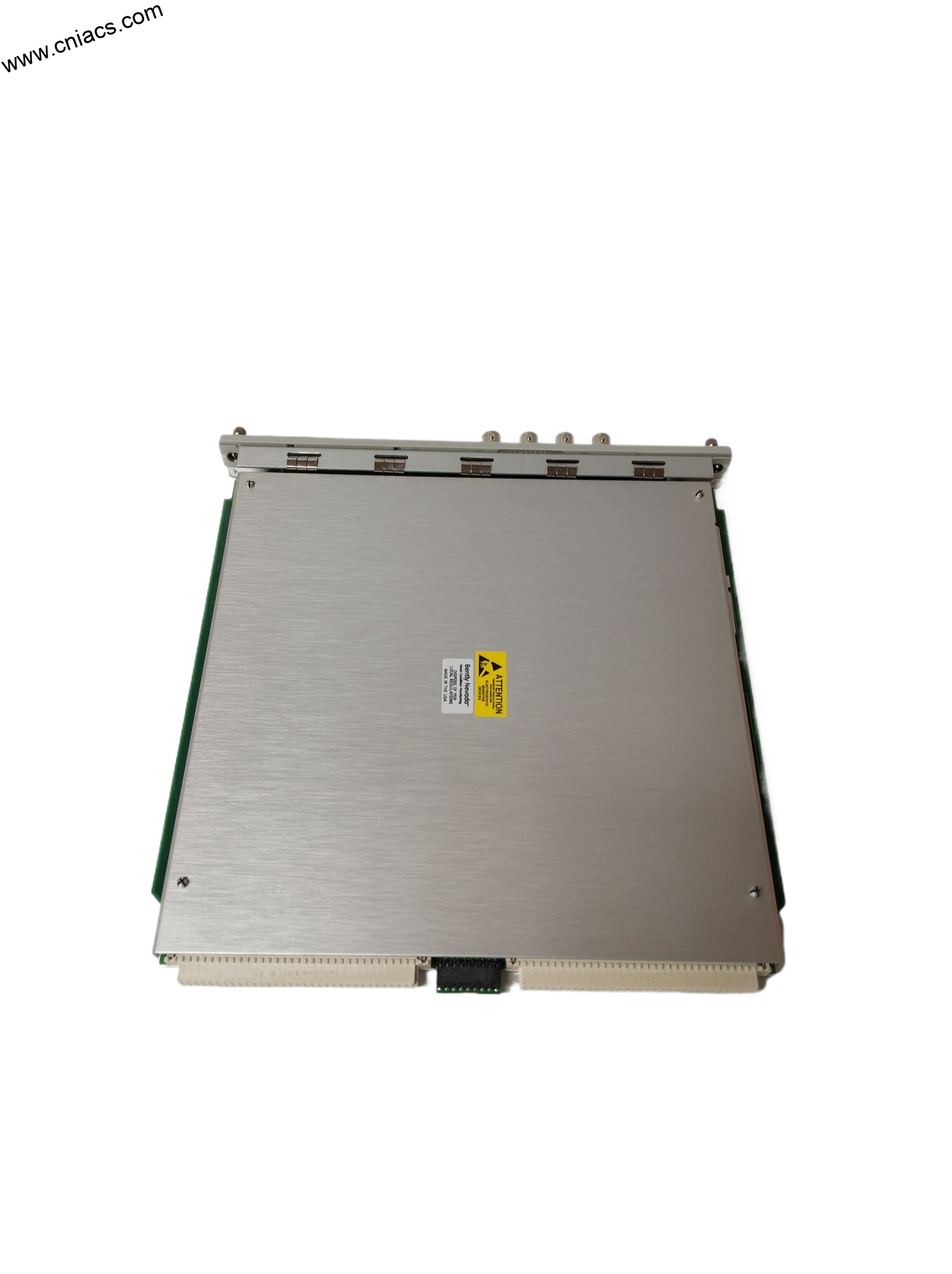

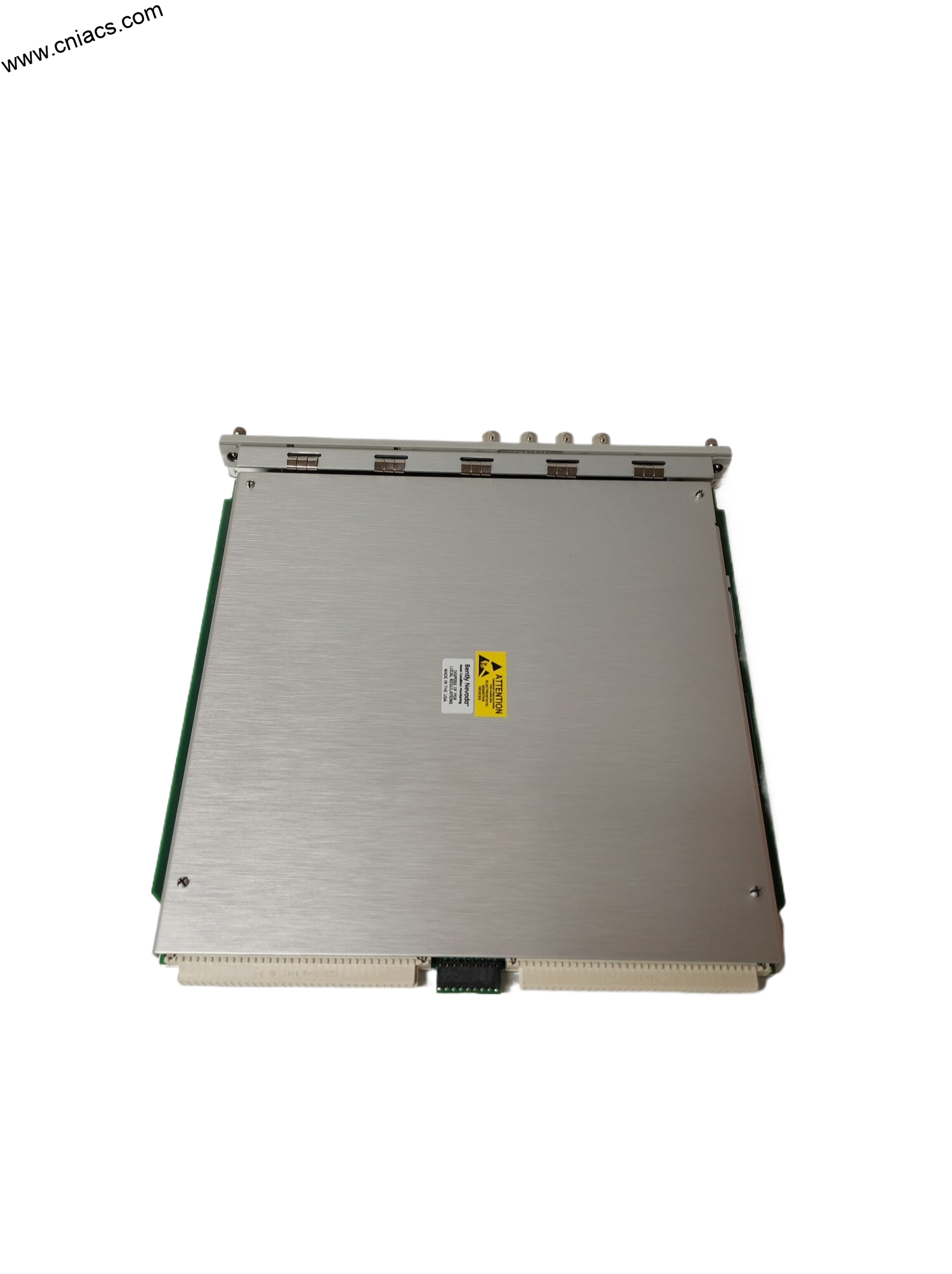

BENTLY Nevada 3300/12-02-22-00 Industrial Power Supply Module

.jpg)

Introducing the BENTLY Nevada: Your Ultimate Solution for Advanced Machinery Condition Monitoring

The BENTLY Nevada series has long been recognized as a benchmark in the realm of condition monitoring and machinery protection. Built to deliver unparalleled performance, the BENTLY Nevada model combines state-of-the-art technology with user-friendly features, making it a top choice for industries that demand reliability and precision.

Key Technical Features

The BENTLY Nevada is designed with a robust architecture that ensures exceptional performance in the most demanding environments. It features advanced vibration monitoring technology, which provides real-time data on machine health, helping to predict failures before they occur. Key technical features include:

1. **Multi-Channel Monitoring**: The BENTLY Nevada supports multiple channels, allowing for comprehensive monitoring of several machinery components simultaneously. This multi-channel capability is crucial for complex systems where multiple variables need to be assessed.

2. **High-Resolution Data Acquisition**: With a high sampling rate, the BENTLY Nevada captures detailed vibration data, enabling accurate analysis and diagnostics. This feature is essential for identifying subtle changes in machine behavior that might indicate potential issues.

3. **User-Friendly Interface**: The intuitive interface allows users to set up and configure the system with ease. The graphical representation of data enhances understanding and decision-making.

4. **Robust Communication Protocols**: Equipped with advanced communication options, the BENTLY Nevada can seamlessly integrate with existing automation systems. This ensures that your machinery health data can be accessed and analyzed in real-time.

5. **Environmental Resilience**: Designed to operate in harsh industrial conditions, the BENTLY Nevada is built to withstand extreme temperatures, dust, and vibration, ensuring longevity and reliability.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for various industries, including oil and gas, manufacturing, power generation, and water treatment. Here are some common usage scenarios:

– **Oil and Gas Exploration**: In the oil and gas sector, the BENTLY Nevada is invaluable for monitoring pumps, compressors, and turbines. Its predictive maintenance capabilities help prevent costly downtimes and extend equipment life.

– **Manufacturing Facilities**: In manufacturing plants, the BENTLY Nevada can be used to monitor assembly line machinery, ensuring that any deviations in performance are detected early. This capability enhances productivity and reduces the risk of unplanned stoppages.

– **Power Generation**: Power plants utilize the BENTLY Nevada to monitor critical machinery such as generators and turbines.

The above parameters are for reference only. Please contact our technical team for precise selection.

The BENTLY Nevada series has long been recognized as a benchmark in the realm of condition monitoring and machinery protection. Built to deliver unparalleled performance, the BENTLY Nevada model combines state-of-the-art technology with user-friendly features, making it a top choice for industries that demand reliability and precision.

Key Technical Features

The BENTLY Nevada is designed with a robust architecture that ensures exceptional performance in the most demanding environments. It features advanced vibration monitoring technology, which provides real-time data on machine health, helping to predict failures before they occur. Key technical features include:

1. **Multi-Channel Monitoring**: The BENTLY Nevada supports multiple channels, allowing for comprehensive monitoring of several machinery components simultaneously. This multi-channel capability is crucial for complex systems where multiple variables need to be assessed.

2. **High-Resolution Data Acquisition**: With a high sampling rate, the BENTLY Nevada captures detailed vibration data, enabling accurate analysis and diagnostics. This feature is essential for identifying subtle changes in machine behavior that might indicate potential issues.

3. **User-Friendly Interface**: The intuitive interface allows users to set up and configure the system with ease. The graphical representation of data enhances understanding and decision-making.

4. **Robust Communication Protocols**: Equipped with advanced communication options, the BENTLY Nevada can seamlessly integrate with existing automation systems. This ensures that your machinery health data can be accessed and analyzed in real-time.

5. **Environmental Resilience**: Designed to operate in harsh industrial conditions, the BENTLY Nevada is built to withstand extreme temperatures, dust, and vibration, ensuring longevity and reliability.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for various industries, including oil and gas, manufacturing, power generation, and water treatment. Here are some common usage scenarios:

– **Oil and Gas Exploration**: In the oil and gas sector, the BENTLY Nevada is invaluable for monitoring pumps, compressors, and turbines. Its predictive maintenance capabilities help prevent costly downtimes and extend equipment life.

– **Manufacturing Facilities**: In manufacturing plants, the BENTLY Nevada can be used to monitor assembly line machinery, ensuring that any deviations in performance are detected early. This capability enhances productivity and reduces the risk of unplanned stoppages.

– **Power Generation**: Power plants utilize the BENTLY Nevada to monitor critical machinery such as generators and turbines.

The above parameters are for reference only. Please contact our technical team for precise selection.

.jpg?v=1739320884)

-300x300.png?v=1739321142)

There are no reviews yet.