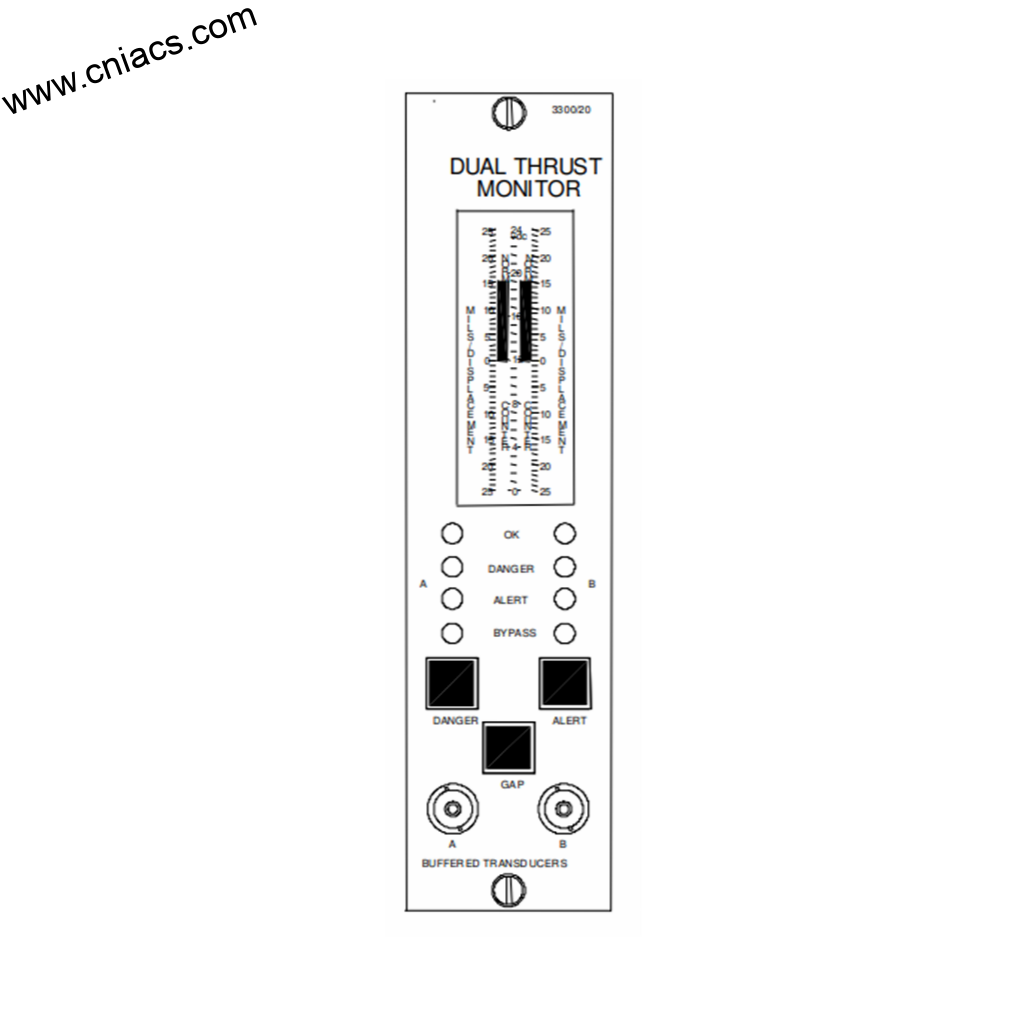

BENTLY Nevada 3300 XL Extension Cable, 330130-085-02-00, Control System Accessories

Introducing the BENTLY Nevada, an innovative solution from BENTLY, a leading name in automation products that are engineered for precision and reliability. Designed for sophisticated monitoring and control applications, the BENTLY Nevada series takes your industrial automation capabilities to the next level.

Key Technical Features

At the heart of the BENTLY Nevada system are its advanced monitoring capabilities, featuring real-time data acquisition and analysis to ensure optimal performance of machinery. The system is designed to operate seamlessly in demanding environments, offering robust protection for critical rotating equipment. Key technical features include:

1. **Multi-Channel Monitoring**: The BENTLY Nevada supports multiple channels, allowing users to monitor various parameters simultaneously. This feature is particularly beneficial for complex systems where various metrics must be tracked at once.

2. **High Sensitivity Sensors**: Equipped with high-sensitivity sensors, the BENTLY Nevada detects even the slightest variations in vibration, temperature, and other critical measurements. This ensures early detection of potential issues, minimizing downtime and maintenance costs.

3. **User-Friendly Interface**: The intuitive interface of the BENTLY Nevada enables quick access to real-time data, historical trends, and alert settings. This means operators can make informed decisions rapidly, enhancing operational efficiency.

4. **Integration Capabilities**: The BENTLY Nevada is designed to integrate seamlessly with other BENTLY automation products and third-party systems, making it a versatile choice for diverse applications.

5. **Scalability**: As your operations grow, the BENTLY Nevada system can be easily scaled to accommodate additional channels or new sensors, ensuring that you are always equipped to handle evolving monitoring needs.

Usage Scenarios

The BENTLY Nevada system excels in a variety of industries and applications. In the power generation sector, it is invaluable for monitoring turbines and generators, helping to prevent catastrophic failures and optimize performance. In oil and gas applications, the BENTLY Nevada can be used to monitor pumps, compressors, and other critical machinery, ensuring that operations run smoothly and efficiently.

Additionally, manufacturing facilities benefit from the BENTLY Nevada's ability to provide real-time insights into the condition of machinery, allowing for predictive maintenance strategies that reduce unplanned downtime. In aerospace, marine, and transportation sectors, the system's capability to monitor complex systems in real-time is crucial for safety and operational integrity.

Comparison with Other Models

When compared to other models in the BENTLY lineup, such as the BENTLY 3500/20 and

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

At the heart of the BENTLY Nevada system are its advanced monitoring capabilities, featuring real-time data acquisition and analysis to ensure optimal performance of machinery. The system is designed to operate seamlessly in demanding environments, offering robust protection for critical rotating equipment. Key technical features include:

1. **Multi-Channel Monitoring**: The BENTLY Nevada supports multiple channels, allowing users to monitor various parameters simultaneously. This feature is particularly beneficial for complex systems where various metrics must be tracked at once.

2. **High Sensitivity Sensors**: Equipped with high-sensitivity sensors, the BENTLY Nevada detects even the slightest variations in vibration, temperature, and other critical measurements. This ensures early detection of potential issues, minimizing downtime and maintenance costs.

3. **User-Friendly Interface**: The intuitive interface of the BENTLY Nevada enables quick access to real-time data, historical trends, and alert settings. This means operators can make informed decisions rapidly, enhancing operational efficiency.

4. **Integration Capabilities**: The BENTLY Nevada is designed to integrate seamlessly with other BENTLY automation products and third-party systems, making it a versatile choice for diverse applications.

5. **Scalability**: As your operations grow, the BENTLY Nevada system can be easily scaled to accommodate additional channels or new sensors, ensuring that you are always equipped to handle evolving monitoring needs.

Usage Scenarios

The BENTLY Nevada system excels in a variety of industries and applications. In the power generation sector, it is invaluable for monitoring turbines and generators, helping to prevent catastrophic failures and optimize performance. In oil and gas applications, the BENTLY Nevada can be used to monitor pumps, compressors, and other critical machinery, ensuring that operations run smoothly and efficiently.

Additionally, manufacturing facilities benefit from the BENTLY Nevada's ability to provide real-time insights into the condition of machinery, allowing for predictive maintenance strategies that reduce unplanned downtime. In aerospace, marine, and transportation sectors, the system's capability to monitor complex systems in real-time is crucial for safety and operational integrity.

Comparison with Other Models

When compared to other models in the BENTLY lineup, such as the BENTLY 3500/20 and

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.jpg?v=1739320885)

There are no reviews yet.