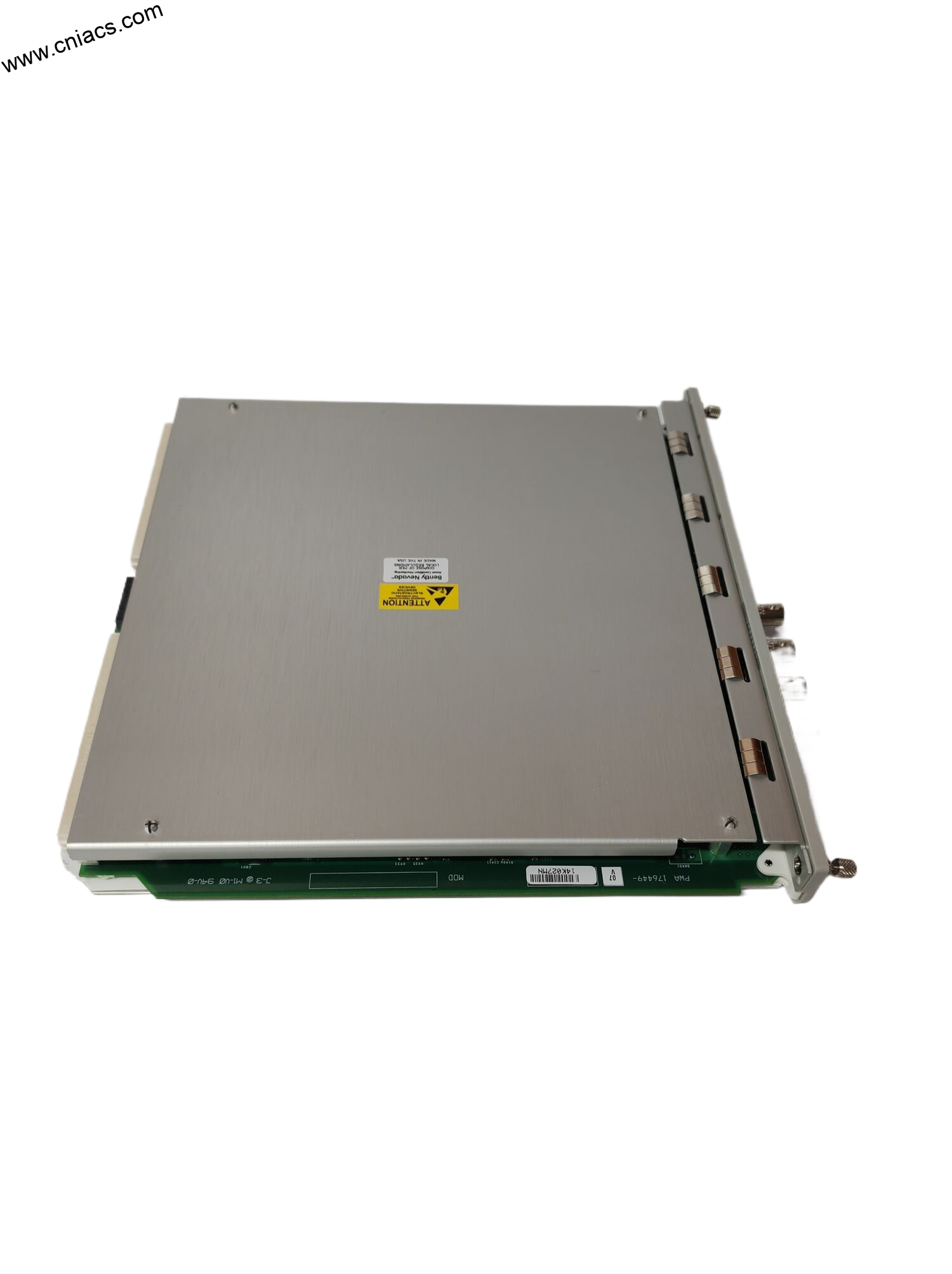

BENTLY Nevada 330103-00-10-10-02-00 Precision Proximity Probes for Advanced Control Systems

Introducing the BENTLY Nevada 330103-00-10-10-02-00, a cutting-edge solution in the realm of condition monitoring and predictive maintenance. This model stands out within the BENTLY automation products lineup, providing unparalleled reliability and performance tailored for industrial applications.

Key Technical Features

The BENTLY Nevada 330103-00-10-10-02-00 is engineered for superior performance in vibration monitoring and analysis. With a robust design, it boasts an impressive range of features that make it indispensable for equipment health management.

1. **Advanced Vibration Monitoring**: The device is equipped with state-of-the-art sensors that accurately measure vibration levels, enabling early detection of potential equipment failures. This proactive approach to maintenance extends the lifespan of machinery and reduces unplanned downtime.

2. **Multi-Channel Capability**: Featuring a multi-channel architecture, the BENTLY Nevada 330103-00-10-10-02-00 can monitor multiple points on machinery simultaneously. This allows for comprehensive analysis and ensures that no critical data is overlooked in your monitoring efforts.

3. **User-Friendly Interface**: The intuitive interface makes it easy for operators to navigate through data and analytics, ensuring timely and informed decision-making. It supports seamless integration with existing control systems, enhancing operational efficiency.

4. **High-Precision Data Acquisition**: With its high sampling rates and data resolution, this model provides detailed insights into machinery performance. This data is essential for trend analysis and predictive maintenance strategies.

5. **Durable Design**: Built to withstand harsh industrial environments, the BENTLY Nevada 330103-00-10-10-02-00 is resistant to dust, moisture, and extreme temperatures, ensuring reliable operation in challenging conditions.

Usage Scenarios

The versatility of the BENTLY Nevada 330103-00-10-10-02-00 makes it suitable for a wide range of applications across various industries.

1. **Power Generation**: In power plants, the BENTLY Nevada system can monitor turbines and generators, providing critical data that helps prevent failures and optimize performance.

2. **Oil and Gas**: The device is particularly valuable in the oil and gas sector, where rotating equipment is essential. Its ability to detect anomalies in compressors and pumps can significantly enhance operational safety and efficiency.

3. **Manufacturing**: Within manufacturing facilities, this model can be utilized to monitor machinery such as conveyors, motors, and gearboxes,

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY Nevada 330103-00-10-10-02-00 is engineered for superior performance in vibration monitoring and analysis. With a robust design, it boasts an impressive range of features that make it indispensable for equipment health management.

1. **Advanced Vibration Monitoring**: The device is equipped with state-of-the-art sensors that accurately measure vibration levels, enabling early detection of potential equipment failures. This proactive approach to maintenance extends the lifespan of machinery and reduces unplanned downtime.

2. **Multi-Channel Capability**: Featuring a multi-channel architecture, the BENTLY Nevada 330103-00-10-10-02-00 can monitor multiple points on machinery simultaneously. This allows for comprehensive analysis and ensures that no critical data is overlooked in your monitoring efforts.

3. **User-Friendly Interface**: The intuitive interface makes it easy for operators to navigate through data and analytics, ensuring timely and informed decision-making. It supports seamless integration with existing control systems, enhancing operational efficiency.

4. **High-Precision Data Acquisition**: With its high sampling rates and data resolution, this model provides detailed insights into machinery performance. This data is essential for trend analysis and predictive maintenance strategies.

5. **Durable Design**: Built to withstand harsh industrial environments, the BENTLY Nevada 330103-00-10-10-02-00 is resistant to dust, moisture, and extreme temperatures, ensuring reliable operation in challenging conditions.

Usage Scenarios

The versatility of the BENTLY Nevada 330103-00-10-10-02-00 makes it suitable for a wide range of applications across various industries.

1. **Power Generation**: In power plants, the BENTLY Nevada system can monitor turbines and generators, providing critical data that helps prevent failures and optimize performance.

2. **Oil and Gas**: The device is particularly valuable in the oil and gas sector, where rotating equipment is essential. Its ability to detect anomalies in compressors and pumps can significantly enhance operational safety and efficiency.

3. **Manufacturing**: Within manufacturing facilities, this model can be utilized to monitor machinery such as conveyors, motors, and gearboxes,

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.