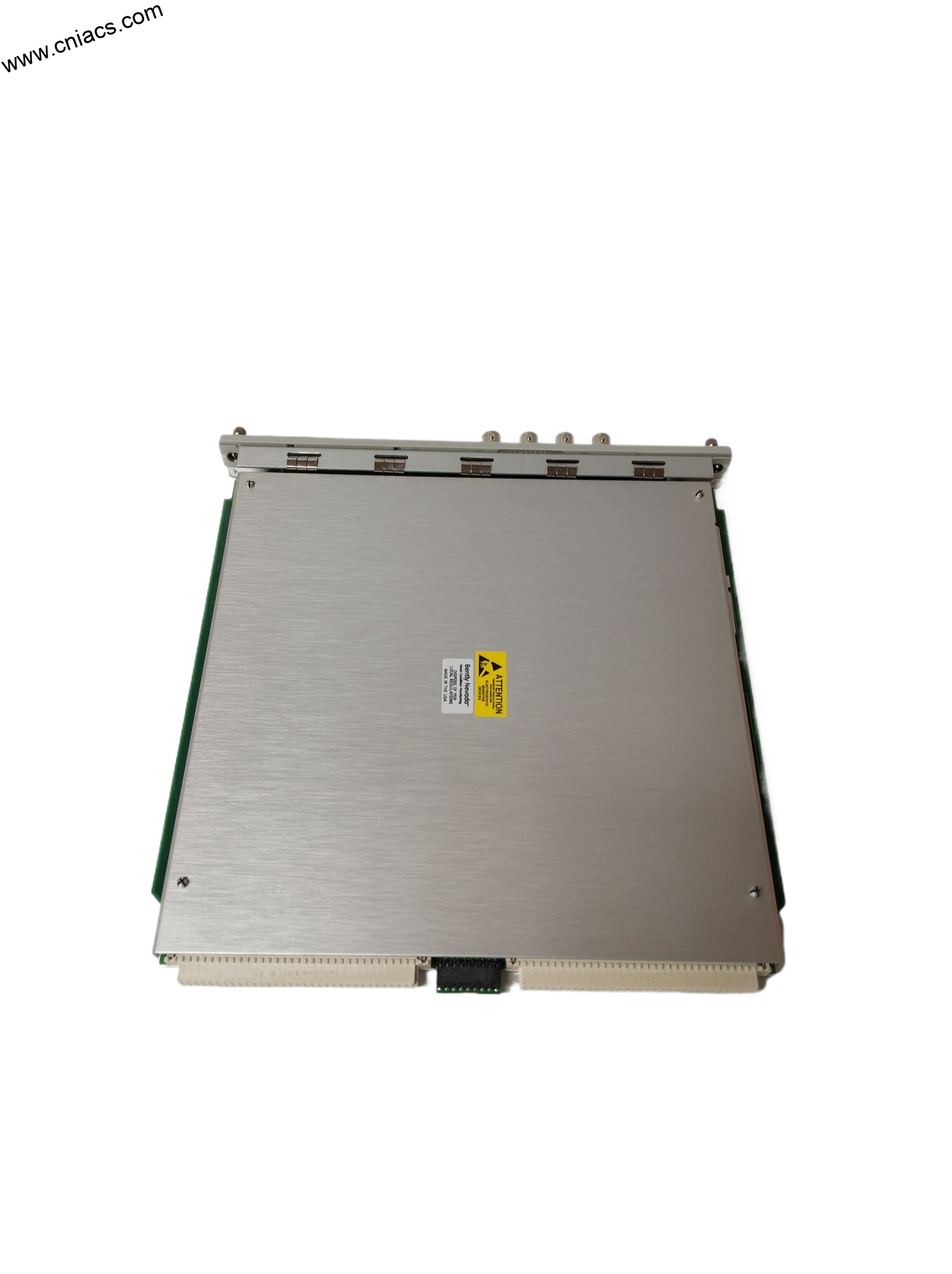

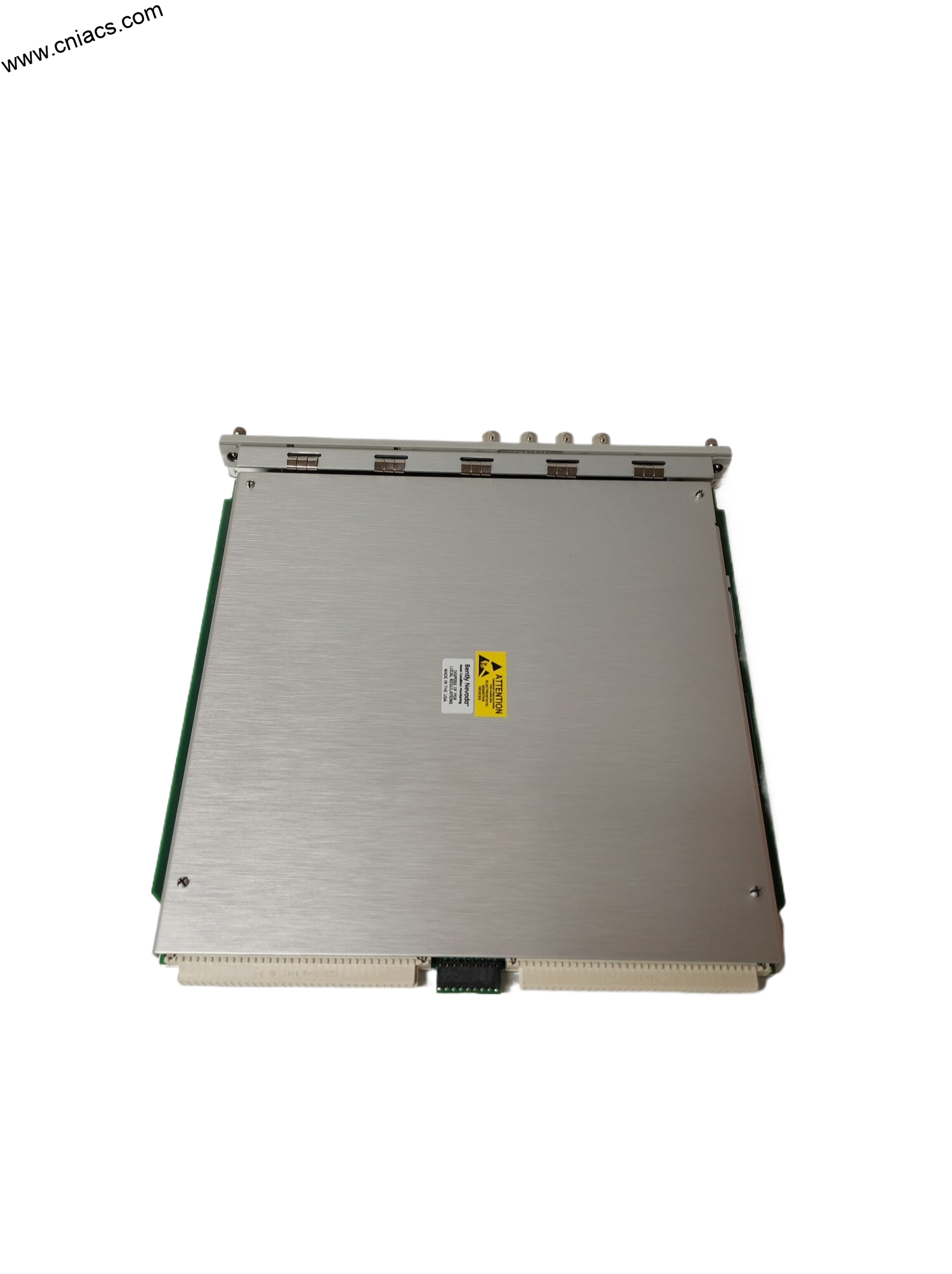

BENTLY Nevada 330103-05-10-02-00 Precision Proximity Probes for Industrial Control Systems

Introducing the BENTLY Nevada 330103-05-10-02-00, a state-of-the-art solution in industrial automation and monitoring. As part of the renowned BENTLY brand, this model stands out due to its advanced capabilities and reliability in managing critical machinery. Designed for rigorous environments, the BENTLY Nevada 330103-05-10-02-00 is engineered to enhance performance and extend the life of your industrial assets.

Key Technical Features

The BENTLY Nevada 330103-05-10-02-00 boasts an array of technical specifications that make it a preferred choice among professionals in various industries. This model features advanced monitoring capabilities, including vibration analysis, temperature monitoring, and dynamic data acquisition. With its robust sensor technology, it provides real-time insights into machinery performance, helping to identify potential issues before they escalate into costly failures.

The device is equipped with a high-speed digital processor that ensures rapid data processing and accurate diagnostics. The intuitive user interface allows for seamless navigation and configuration, facilitating easy integration into existing systems. Furthermore, the BENTLY Nevada 330103-05-10-02-00 supports various communication protocols, ensuring compatibility with a range of automation systems, making it a versatile component in your industrial setup.

Usage Scenarios

The BENTLY Nevada 330103-05-10-02-00 is suitable for a wide range of applications across multiple industries, including oil and gas, power generation, and manufacturing. Its capabilities make it ideal for monitoring rotating machinery such as turbines, compressors, and pumps. For instance, in a power generation facility, this model can continuously monitor the performance of gas turbines to ensure optimal operation and prevent unexpected shutdowns.

In manufacturing environments, the BENTLY Nevada 330103-05-10-02-00 can be employed to monitor the health of critical machinery, allowing for predictive maintenance strategies. By analyzing vibration patterns and temperature fluctuations, operators can schedule maintenance during planned downtimes, minimizing disruption to production processes and maximizing operational efficiency.

Comparison with Other Models

When compared to other models within the BENTLY lineup, such as the BENTLY 3500/20 125744-02 and BENTLY 3500/42M, the BENTLY Nevada 330103-05-10-02-00 is tailored for more advanced monitoring needs. While the BENTLY 3500 series offers excellent performance and reliability, the 330103-05-10

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY Nevada 330103-05-10-02-00 boasts an array of technical specifications that make it a preferred choice among professionals in various industries. This model features advanced monitoring capabilities, including vibration analysis, temperature monitoring, and dynamic data acquisition. With its robust sensor technology, it provides real-time insights into machinery performance, helping to identify potential issues before they escalate into costly failures.

The device is equipped with a high-speed digital processor that ensures rapid data processing and accurate diagnostics. The intuitive user interface allows for seamless navigation and configuration, facilitating easy integration into existing systems. Furthermore, the BENTLY Nevada 330103-05-10-02-00 supports various communication protocols, ensuring compatibility with a range of automation systems, making it a versatile component in your industrial setup.

Usage Scenarios

The BENTLY Nevada 330103-05-10-02-00 is suitable for a wide range of applications across multiple industries, including oil and gas, power generation, and manufacturing. Its capabilities make it ideal for monitoring rotating machinery such as turbines, compressors, and pumps. For instance, in a power generation facility, this model can continuously monitor the performance of gas turbines to ensure optimal operation and prevent unexpected shutdowns.

In manufacturing environments, the BENTLY Nevada 330103-05-10-02-00 can be employed to monitor the health of critical machinery, allowing for predictive maintenance strategies. By analyzing vibration patterns and temperature fluctuations, operators can schedule maintenance during planned downtimes, minimizing disruption to production processes and maximizing operational efficiency.

Comparison with Other Models

When compared to other models within the BENTLY lineup, such as the BENTLY 3500/20 125744-02 and BENTLY 3500/42M, the BENTLY Nevada 330103-05-10-02-00 is tailored for more advanced monitoring needs. While the BENTLY 3500 series offers excellent performance and reliability, the 330103-05-10

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.jpg?v=1739320885)

There are no reviews yet.