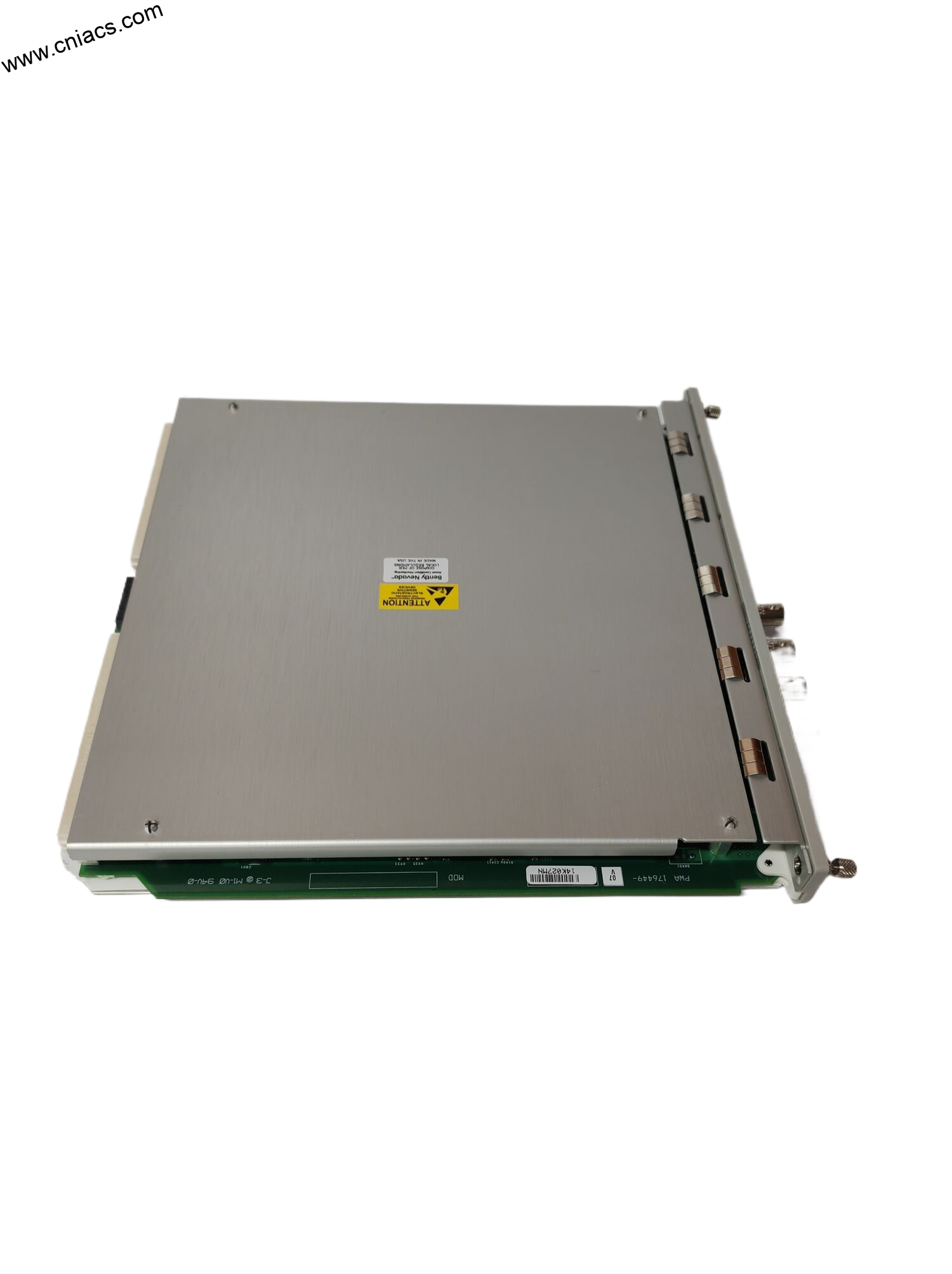

BENTLY Nevada 330104-00-04-10-02-05; Producer:bently-nevada

Introducing the BENTLY Nevada: The Pinnacle of Condition Monitoring Technology

The BENTLY Nevada series has long been synonymous with reliability and innovation in condition monitoring. Designed for precision and durability, the BENTLY Nevada model stands out in a crowded marketplace of automation products. This state-of-the-art system provides unparalleled insights into the health of your machinery, ensuring that your operations run smoothly and efficiently.

Key Technical Features

At the heart of the BENTLY Nevada is its advanced data acquisition and analysis technology. The model features high-resolution sensors that monitor vibration, temperature, and other critical parameters, allowing for real-time data collection. With a robust built-in signal processing capability, the BENTLY Nevada can filter noise and provide accurate readings even in challenging environments.

One of the standout features of the BENTLY Nevada is its scalability. Whether you are monitoring a single piece of equipment or an entire plant, the system can be tailored to meet your specific needs. This flexibility is supported by a comprehensive suite of software applications that enable users to visualize data trends, set alarms, and generate reports with ease.

Additionally, the BENTLY Nevada integrates seamlessly with existing BENTLY automation products, such as the BENTLY 3500/20 and BENTLY 3500/45, allowing for a cohesive monitoring strategy that enhances productivity. The model is designed to withstand harsh conditions, featuring IP67-rated enclosures that protect against dust and moisture, making it suitable for industrial environments.

Usage Scenarios

The BENTLY Nevada is ideal for a wide range of applications, making it a versatile choice for industries such as oil and gas, power generation, and manufacturing. In oil and gas facilities, for instance, the system can be deployed to monitor critical rotating equipment such as pumps, compressors, and turbines, helping to prevent unexpected failures that can lead to costly downtimes.

In power generation plants, the BENTLY Nevada can be used to monitor generator bearings and steam turbines, providing operators with real-time insights that facilitate proactive maintenance strategies. By detecting early signs of wear or misalignment, the system helps extend the lifespan of equipment while ensuring that energy production remains optimal.

Manufacturers can also benefit from the BENTLY Nevada's advanced capabilities, employing it to monitor production machinery and ensure that operations are running at peak efficiency. By integrating the BENTLY Nevada with other BENTLY automation products, manufacturers can create a robust monitoring framework that enhances overall operational performance.

Comparison with Other Models

When

The above parameters are for reference only. Please contact our technical team for precise selection.

The BENTLY Nevada series has long been synonymous with reliability and innovation in condition monitoring. Designed for precision and durability, the BENTLY Nevada model stands out in a crowded marketplace of automation products. This state-of-the-art system provides unparalleled insights into the health of your machinery, ensuring that your operations run smoothly and efficiently.

Key Technical Features

At the heart of the BENTLY Nevada is its advanced data acquisition and analysis technology. The model features high-resolution sensors that monitor vibration, temperature, and other critical parameters, allowing for real-time data collection. With a robust built-in signal processing capability, the BENTLY Nevada can filter noise and provide accurate readings even in challenging environments.

One of the standout features of the BENTLY Nevada is its scalability. Whether you are monitoring a single piece of equipment or an entire plant, the system can be tailored to meet your specific needs. This flexibility is supported by a comprehensive suite of software applications that enable users to visualize data trends, set alarms, and generate reports with ease.

Additionally, the BENTLY Nevada integrates seamlessly with existing BENTLY automation products, such as the BENTLY 3500/20 and BENTLY 3500/45, allowing for a cohesive monitoring strategy that enhances productivity. The model is designed to withstand harsh conditions, featuring IP67-rated enclosures that protect against dust and moisture, making it suitable for industrial environments.

Usage Scenarios

The BENTLY Nevada is ideal for a wide range of applications, making it a versatile choice for industries such as oil and gas, power generation, and manufacturing. In oil and gas facilities, for instance, the system can be deployed to monitor critical rotating equipment such as pumps, compressors, and turbines, helping to prevent unexpected failures that can lead to costly downtimes.

In power generation plants, the BENTLY Nevada can be used to monitor generator bearings and steam turbines, providing operators with real-time insights that facilitate proactive maintenance strategies. By detecting early signs of wear or misalignment, the system helps extend the lifespan of equipment while ensuring that energy production remains optimal.

Manufacturers can also benefit from the BENTLY Nevada's advanced capabilities, employing it to monitor production machinery and ensure that operations are running at peak efficiency. By integrating the BENTLY Nevada with other BENTLY automation products, manufacturers can create a robust monitoring framework that enhances overall operational performance.

Comparison with Other Models

When

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.