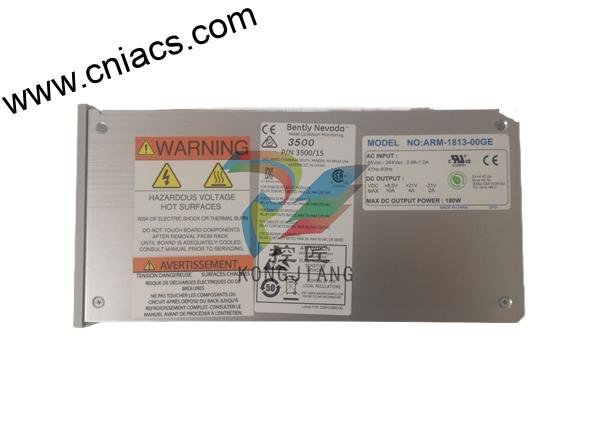

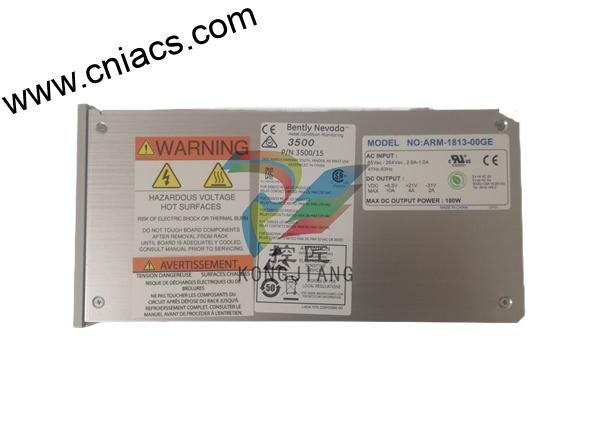

BENTLY Nevada 330104-00-07-10-01-05, Proximity Probe for Advanced Industrial Control Systems

Introducing the BENTLY Nevada, a pinnacle of reliability and precision in the realm of industrial monitoring and automation solutions. Part of the esteemed BENTLY automation products lineup, the Nevada series stands as a cornerstone for engineers and operators who seek the highest standards in asset protection and performance monitoring.

Key Technical Features

The BENTLY Nevada is designed with advanced technology that ensures optimal performance across a variety of applications. Key features include:

1. **High-Resolution Data Acquisition**: The Nevada model utilizes high-resolution sensors that provide real-time data monitoring. This is crucial for proactive maintenance and minimizing downtime.

2. **Robust Signal Processing**: With sophisticated signal conditioning and processing capabilities, the BENTLY Nevada can filter out noise and deliver accurate readings even in challenging environments.

3. **Flexible Configuration**: The system supports various configurations to accommodate different monitoring needs. Whether you require vibration analysis, temperature monitoring, or pressure sensing, the BENTLY Nevada can be tailored to suit your specifications.

4. **User-Friendly Interface**: The intuitive user interface allows for easy navigation and access to critical performance metrics. Operators can quickly interpret data, enabling swift decision-making.

5. **Scalability**: The BENTLY Nevada is designed to grow with your operations. As your needs change, the system can be expanded or integrated with other BENTLY automation products without hassle.

6. **Robust Build Quality**: Engineered for durability, the Nevada model can withstand extreme conditions, making it ideal for deployment in harsh industrial environments.

Usage Scenarios

The BENTLY Nevada excels in multiple usage scenarios across various industries. It is particularly beneficial in:

1. **Oil and Gas**: In oil rigs and refineries, the Nevada system provides critical monitoring of rotating machinery, helping to prevent failures that could lead to costly downtimes or safety incidents.

2. **Power Generation**: For power plants, the BENTLY Nevada ensures that turbines, generators, and other critical equipment operate at peak efficiency, thereby maximizing energy output and minimizing operational costs.

3. **Manufacturing**: In manufacturing settings, the system can monitor conveyor belts and other machinery, offering predictive maintenance insights that help manufacturers avoid production halts.

4. **Aerospace**: In the aerospace sector, the precision and reliability of the BENTLY Nevada are essential for monitoring high-performance engines and components, ensuring safety and compliance with stringent regulations.

5. **Mining**: The Nevada series can monitor equipment in

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY Nevada is designed with advanced technology that ensures optimal performance across a variety of applications. Key features include:

1. **High-Resolution Data Acquisition**: The Nevada model utilizes high-resolution sensors that provide real-time data monitoring. This is crucial for proactive maintenance and minimizing downtime.

2. **Robust Signal Processing**: With sophisticated signal conditioning and processing capabilities, the BENTLY Nevada can filter out noise and deliver accurate readings even in challenging environments.

3. **Flexible Configuration**: The system supports various configurations to accommodate different monitoring needs. Whether you require vibration analysis, temperature monitoring, or pressure sensing, the BENTLY Nevada can be tailored to suit your specifications.

4. **User-Friendly Interface**: The intuitive user interface allows for easy navigation and access to critical performance metrics. Operators can quickly interpret data, enabling swift decision-making.

5. **Scalability**: The BENTLY Nevada is designed to grow with your operations. As your needs change, the system can be expanded or integrated with other BENTLY automation products without hassle.

6. **Robust Build Quality**: Engineered for durability, the Nevada model can withstand extreme conditions, making it ideal for deployment in harsh industrial environments.

Usage Scenarios

The BENTLY Nevada excels in multiple usage scenarios across various industries. It is particularly beneficial in:

1. **Oil and Gas**: In oil rigs and refineries, the Nevada system provides critical monitoring of rotating machinery, helping to prevent failures that could lead to costly downtimes or safety incidents.

2. **Power Generation**: For power plants, the BENTLY Nevada ensures that turbines, generators, and other critical equipment operate at peak efficiency, thereby maximizing energy output and minimizing operational costs.

3. **Manufacturing**: In manufacturing settings, the system can monitor conveyor belts and other machinery, offering predictive maintenance insights that help manufacturers avoid production halts.

4. **Aerospace**: In the aerospace sector, the precision and reliability of the BENTLY Nevada are essential for monitoring high-performance engines and components, ensuring safety and compliance with stringent regulations.

5. **Mining**: The Nevada series can monitor equipment in

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.png?v=1739321142)

-300x300.jpg?v=1739320885)

There are no reviews yet.