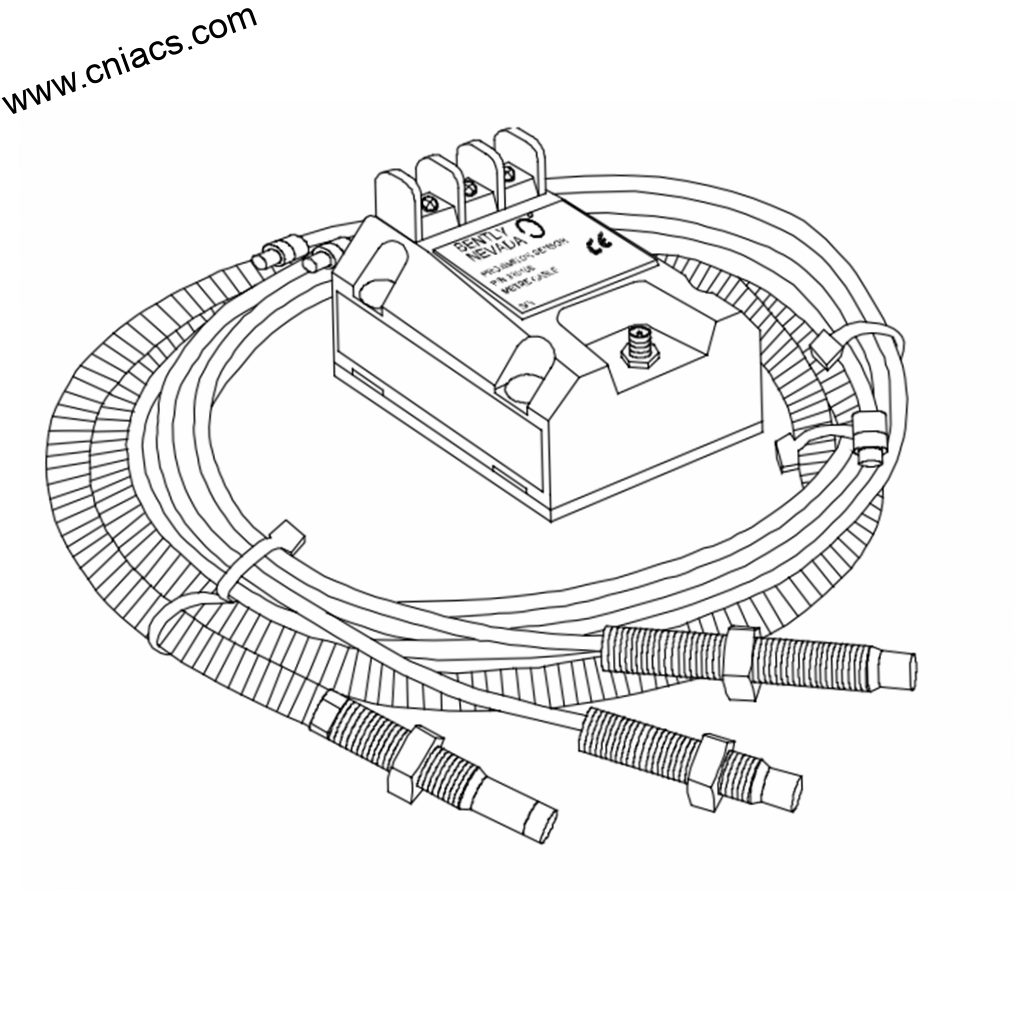

BENTLY Nevada 330104-00-08-10-01-CN | 3300 XL Proximity Probes, 8mm

Introducing the BENTLY Nevada: The Pinnacle of Condition Monitoring and Vibration Analysis

In the realm of industrial automation and predictive maintenance, BENTLY Nevada stands out as a beacon of reliability and innovation. Designed specifically for the demanding conditions of modern manufacturing and power generation, the BENTLY Nevada series represents a blend of cutting-edge technology, ease of use, and exceptional performance. This comprehensive product description explores the key technical features of the BENTLY Nevada, its diverse usage scenarios, comparisons with other models, and highlights related offerings from the BENTLY portfolio.

Key Technical Features

The BENTLY Nevada series is engineered with advanced capabilities that set it apart in the field of condition monitoring and vibration analysis. Among its key features are:

1. **Real-Time Monitoring**: The BENTLY Nevada provides continuous real-time monitoring of critical machine parameters, enabling operators to identify potential issues before they escalate into costly failures.

2. **High-Resolution Data Acquisition**: With high-frequency sampling rates, the system captures detailed vibration data, ensuring accurate diagnostics and analysis.

3. **Multi-Channel Compatibility**: BENTLY Nevada supports multi-channel configurations, allowing for simultaneous monitoring of multiple machines or systems, which is essential in complex industrial environments.

4. **User-Friendly Interface**: Featuring an intuitive interface, the BENTLY Nevada allows users to easily navigate through data and analysis tools, making it accessible for both seasoned professionals and newcomers to condition monitoring.

5. **Robust Design**: Built to withstand harsh industrial environments, the BENTLY Nevada is durable and reliable, ensuring consistent performance even in the most challenging conditions.

6. **Integration with BENTLY Automation Products**: Seamlessly integrate with other BENTLY automation products for a comprehensive solution that enhances predictive maintenance strategies across your facility.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for a wide array of industrial applications. Common usage scenarios include:

– **Power Generation**: In power plants, the BENTLY Nevada monitors critical rotating equipment such as turbines and generators, providing insights that help optimize performance and minimize downtime.

– **Oil and Gas**: Used extensively in oil refineries and offshore platforms, the BENTLY Nevada ensures the reliability of pumps, compressors, and other rotating machinery, safeguarding against catastrophic failures.

– **Manufacturing**: In manufacturing facilities, the system supports the condition monitoring of assembly lines, conveyor systems, and CNC machines, enhancing efficiency and reducing maintenance costs.

–

The above parameters are for reference only. Please contact our technical team for precise selection.

In the realm of industrial automation and predictive maintenance, BENTLY Nevada stands out as a beacon of reliability and innovation. Designed specifically for the demanding conditions of modern manufacturing and power generation, the BENTLY Nevada series represents a blend of cutting-edge technology, ease of use, and exceptional performance. This comprehensive product description explores the key technical features of the BENTLY Nevada, its diverse usage scenarios, comparisons with other models, and highlights related offerings from the BENTLY portfolio.

Key Technical Features

The BENTLY Nevada series is engineered with advanced capabilities that set it apart in the field of condition monitoring and vibration analysis. Among its key features are:

1. **Real-Time Monitoring**: The BENTLY Nevada provides continuous real-time monitoring of critical machine parameters, enabling operators to identify potential issues before they escalate into costly failures.

2. **High-Resolution Data Acquisition**: With high-frequency sampling rates, the system captures detailed vibration data, ensuring accurate diagnostics and analysis.

3. **Multi-Channel Compatibility**: BENTLY Nevada supports multi-channel configurations, allowing for simultaneous monitoring of multiple machines or systems, which is essential in complex industrial environments.

4. **User-Friendly Interface**: Featuring an intuitive interface, the BENTLY Nevada allows users to easily navigate through data and analysis tools, making it accessible for both seasoned professionals and newcomers to condition monitoring.

5. **Robust Design**: Built to withstand harsh industrial environments, the BENTLY Nevada is durable and reliable, ensuring consistent performance even in the most challenging conditions.

6. **Integration with BENTLY Automation Products**: Seamlessly integrate with other BENTLY automation products for a comprehensive solution that enhances predictive maintenance strategies across your facility.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for a wide array of industrial applications. Common usage scenarios include:

– **Power Generation**: In power plants, the BENTLY Nevada monitors critical rotating equipment such as turbines and generators, providing insights that help optimize performance and minimize downtime.

– **Oil and Gas**: Used extensively in oil refineries and offshore platforms, the BENTLY Nevada ensures the reliability of pumps, compressors, and other rotating machinery, safeguarding against catastrophic failures.

– **Manufacturing**: In manufacturing facilities, the system supports the condition monitoring of assembly lines, conveyor systems, and CNC machines, enhancing efficiency and reducing maintenance costs.

–

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.jpg?v=1739320885)

There are no reviews yet.