BENTLY Nevada 330180-X2-05 MOD 181634-02 Proximity Sensor

Introducing the BENTLY Nevada 330180-X2-05 MOD: a cutting-edge solution in the realm of condition monitoring and asset protection that represents the pinnacle of BENTLY’s automation products. This advanced model is engineered to provide precise analysis, real-time monitoring, and robust data collection capabilities, making it an indispensable tool for industries reliant on dependable machinery and equipment performance.

Key Technical Features

The BENTLY Nevada 330180-X2-05 MOD is distinguished by its expansive range of technical features that empower users to achieve unparalleled performance efficiency. At its core, this model boasts a highly accurate measurement system that utilizes advanced vibration and temperature sensors to deliver real-time data about equipment health. Its modular design allows for easy integration into existing systems, enhancing flexibility and scalability.

The device supports a wide array of input signals, including vibration, temperature, speed, and displacement, ensuring comprehensive monitoring across various machine types. With an exceptional sampling rate, the 330180-X2-05 MOD enables the capture of transient events, delivering insights that are critical for predictive maintenance strategies. Additionally, the unit's high noise immunity ensures reliable operation even in demanding industrial environments.

Another standout feature is the BENTLY Nevada 330180-X2-05 MOD’s robust communication capabilities. It supports various communication protocols, allowing seamless integration with BENTLY automation products and third-party systems alike. Users can easily access and analyze data through powerful software platforms, streamlining decision-making processes and enhancing overall operational efficiency.

Usage Scenarios

The versatility of the BENTLY Nevada 330180-X2-05 MOD makes it applicable across various sectors, including oil and gas, power generation, manufacturing, and transportation. In oil and gas facilities, for example, the device can monitor pumps and compressors, ensuring they operate within optimal performance ranges and minimizing unplanned downtime. In power generation plants, it provides essential data for turbines and generators, allowing for effective condition-based maintenance strategies that can significantly extend equipment lifespan.

In manufacturing environments, the BENTLY Nevada 330180-X2-05 MOD can be utilized to monitor rotating machinery, conveyor systems, and other critical components, enhancing production reliability and reducing maintenance costs. Its ability to capture and analyze vibration data makes it an ideal choice for companies looking to implement predictive maintenance strategies, ultimately leading to increased uptime and productivity.

Comparison with Other Models

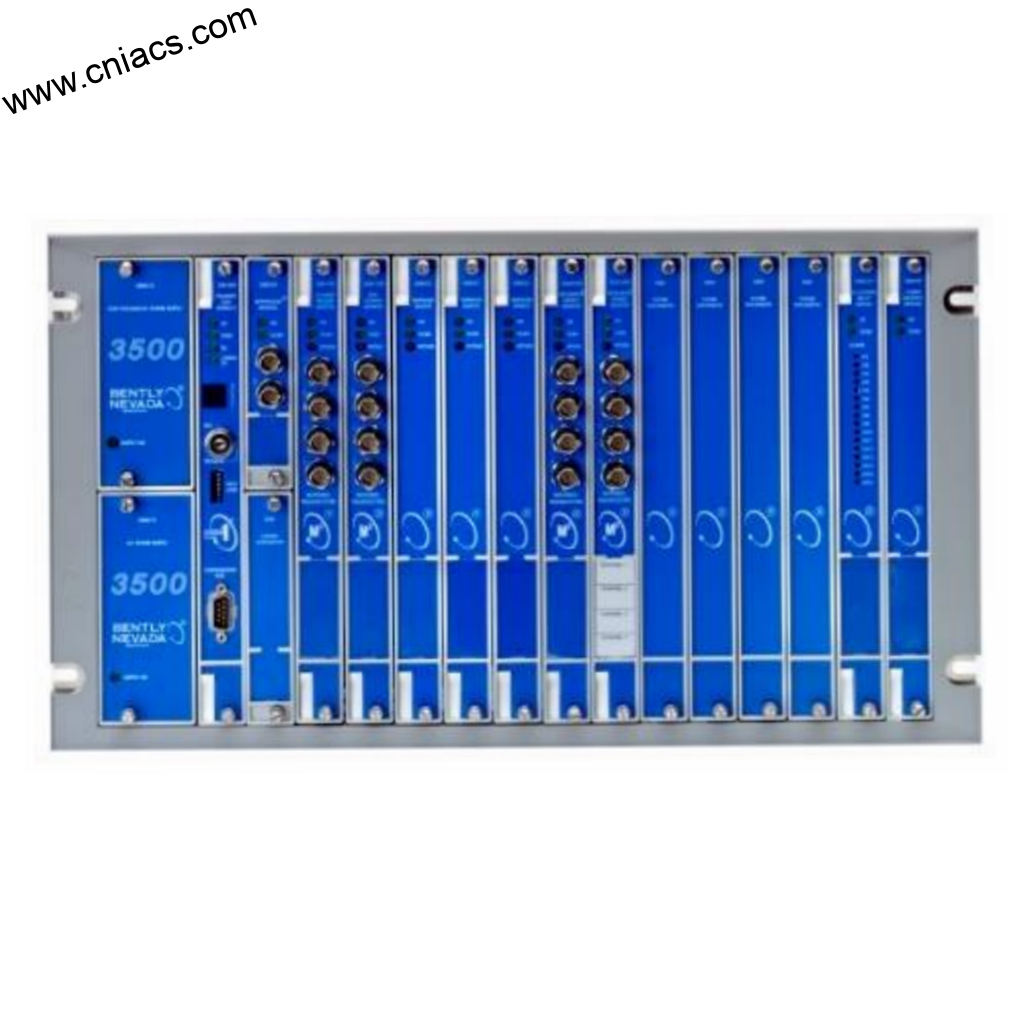

When compared to other models in the BENTLY Nevada lineup, such as the BENTLY 3500/20 and BENTLY

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY Nevada 330180-X2-05 MOD is distinguished by its expansive range of technical features that empower users to achieve unparalleled performance efficiency. At its core, this model boasts a highly accurate measurement system that utilizes advanced vibration and temperature sensors to deliver real-time data about equipment health. Its modular design allows for easy integration into existing systems, enhancing flexibility and scalability.

The device supports a wide array of input signals, including vibration, temperature, speed, and displacement, ensuring comprehensive monitoring across various machine types. With an exceptional sampling rate, the 330180-X2-05 MOD enables the capture of transient events, delivering insights that are critical for predictive maintenance strategies. Additionally, the unit's high noise immunity ensures reliable operation even in demanding industrial environments.

Another standout feature is the BENTLY Nevada 330180-X2-05 MOD’s robust communication capabilities. It supports various communication protocols, allowing seamless integration with BENTLY automation products and third-party systems alike. Users can easily access and analyze data through powerful software platforms, streamlining decision-making processes and enhancing overall operational efficiency.

Usage Scenarios

The versatility of the BENTLY Nevada 330180-X2-05 MOD makes it applicable across various sectors, including oil and gas, power generation, manufacturing, and transportation. In oil and gas facilities, for example, the device can monitor pumps and compressors, ensuring they operate within optimal performance ranges and minimizing unplanned downtime. In power generation plants, it provides essential data for turbines and generators, allowing for effective condition-based maintenance strategies that can significantly extend equipment lifespan.

In manufacturing environments, the BENTLY Nevada 330180-X2-05 MOD can be utilized to monitor rotating machinery, conveyor systems, and other critical components, enhancing production reliability and reducing maintenance costs. Its ability to capture and analyze vibration data makes it an ideal choice for companies looking to implement predictive maintenance strategies, ultimately leading to increased uptime and productivity.

Comparison with Other Models

When compared to other models in the BENTLY Nevada lineup, such as the BENTLY 3500/20 and BENTLY

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.png?v=1739321142)

-300x300.jpg?v=1739320885)

There are no reviews yet.