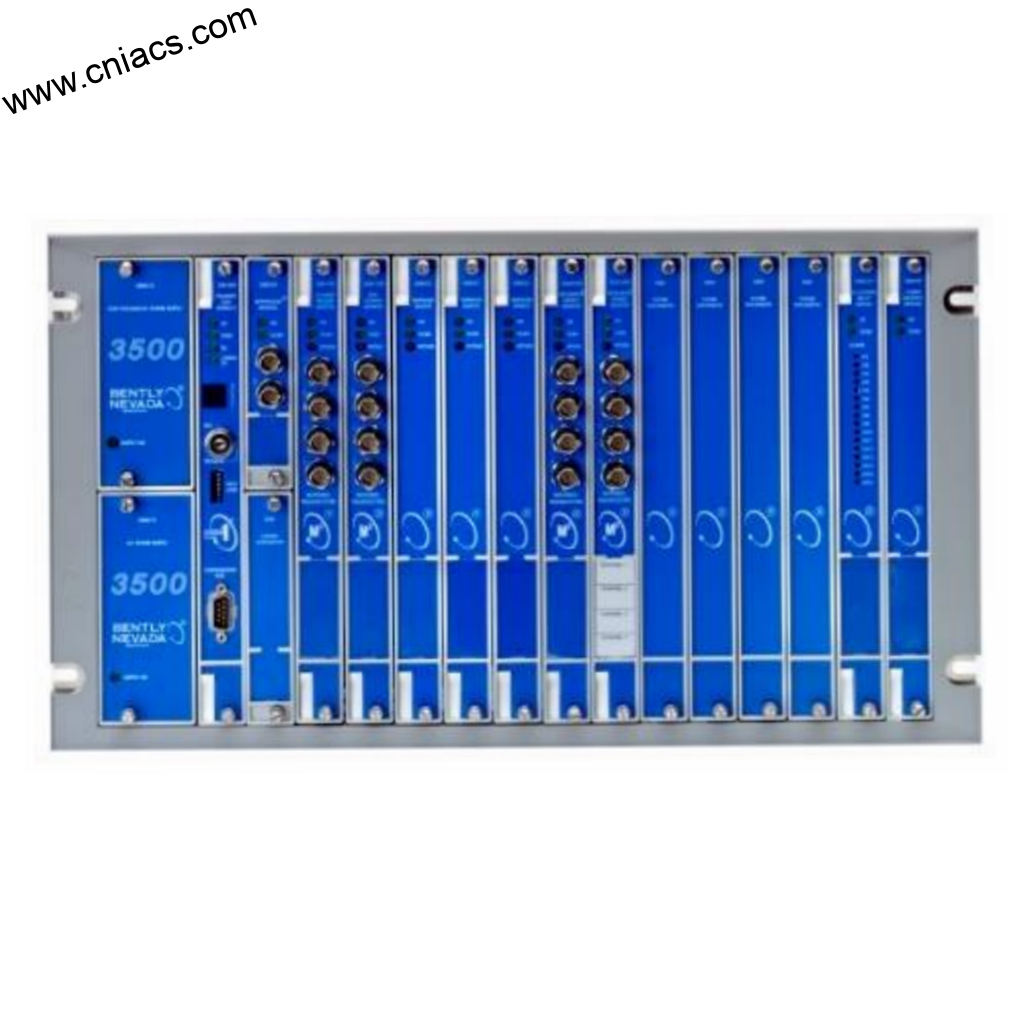

BENTLY Nevada 330930-040-00-05 3300 XL Standard Extension Cable

Introducing the BENTLY Nevada 330930-040-00-05, a pinnacle in BENTLY's range of advanced automation products designed for the performance-driven industries of today. This model is engineered to provide unparalleled monitoring and diagnostics for machinery and industrial processes, ensuring optimal operational efficiency and reliability. With its cutting-edge technology and robust design, the BENTLY Nevada 330930-040-00-05 stands out as an essential tool for maintenance and operational teams looking to enhance their predictive maintenance strategies.

Key Technical Features

The BENTLY Nevada 330930-040-00-05 is packed with features that make it an industry leader in condition monitoring. At its core, this model is equipped with a highly sensitive vibration sensor capable of detecting minute changes in machinery performance, allowing for early fault detection. The device operates across a wide frequency range, ensuring it can monitor various types of rotating equipment, from turbines to pumps.

One of the standout features is its advanced signal processing capabilities. The BENTLY Nevada 330930-040-00-05 employs sophisticated algorithms to analyze vibration data, providing real-time insights into equipment health. Additionally, it supports multiple communication protocols, including Modbus and Ethernet, enabling seamless integration with existing industrial systems and enhancing data accessibility.

The device also boasts a rugged design, making it suitable for harsh industrial environments. Its robust housing is resistant to dust, moisture, and extreme temperatures, ensuring reliable performance in various operational conditions. Furthermore, the BENTLY Nevada 330930-040-00-05 includes built-in redundancy features, ensuring continuous operation even in the event of a component failure.

Usage Scenarios

The versatility of the BENTLY Nevada 330930-040-00-05 makes it suitable for a wide range of applications. In power generation facilities, it can monitor turbine performance, helping to predict failures before they lead to costly outages. In manufacturing plants, it is invaluable for monitoring conveyor systems and motors, ensuring smooth operations and reducing downtime.

Oil and gas industries also benefit significantly from this model, where its ability to monitor drilling equipment and compressors enhances operational safety and efficiency. Additionally, the BENTLY Nevada 330930-040-00-05 is an excellent choice for critical infrastructure applications, such as water treatment facilities, where consistent performance is essential for public health and safety.

Comparison with Other Models

When comparing the BENTLY Nevada 330930-040-00-05 with other models in the BENTLY

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY Nevada 330930-040-00-05 is packed with features that make it an industry leader in condition monitoring. At its core, this model is equipped with a highly sensitive vibration sensor capable of detecting minute changes in machinery performance, allowing for early fault detection. The device operates across a wide frequency range, ensuring it can monitor various types of rotating equipment, from turbines to pumps.

One of the standout features is its advanced signal processing capabilities. The BENTLY Nevada 330930-040-00-05 employs sophisticated algorithms to analyze vibration data, providing real-time insights into equipment health. Additionally, it supports multiple communication protocols, including Modbus and Ethernet, enabling seamless integration with existing industrial systems and enhancing data accessibility.

The device also boasts a rugged design, making it suitable for harsh industrial environments. Its robust housing is resistant to dust, moisture, and extreme temperatures, ensuring reliable performance in various operational conditions. Furthermore, the BENTLY Nevada 330930-040-00-05 includes built-in redundancy features, ensuring continuous operation even in the event of a component failure.

Usage Scenarios

The versatility of the BENTLY Nevada 330930-040-00-05 makes it suitable for a wide range of applications. In power generation facilities, it can monitor turbine performance, helping to predict failures before they lead to costly outages. In manufacturing plants, it is invaluable for monitoring conveyor systems and motors, ensuring smooth operations and reducing downtime.

Oil and gas industries also benefit significantly from this model, where its ability to monitor drilling equipment and compressors enhances operational safety and efficiency. Additionally, the BENTLY Nevada 330930-040-00-05 is an excellent choice for critical infrastructure applications, such as water treatment facilities, where consistent performance is essential for public health and safety.

Comparison with Other Models

When comparing the BENTLY Nevada 330930-040-00-05 with other models in the BENTLY

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.