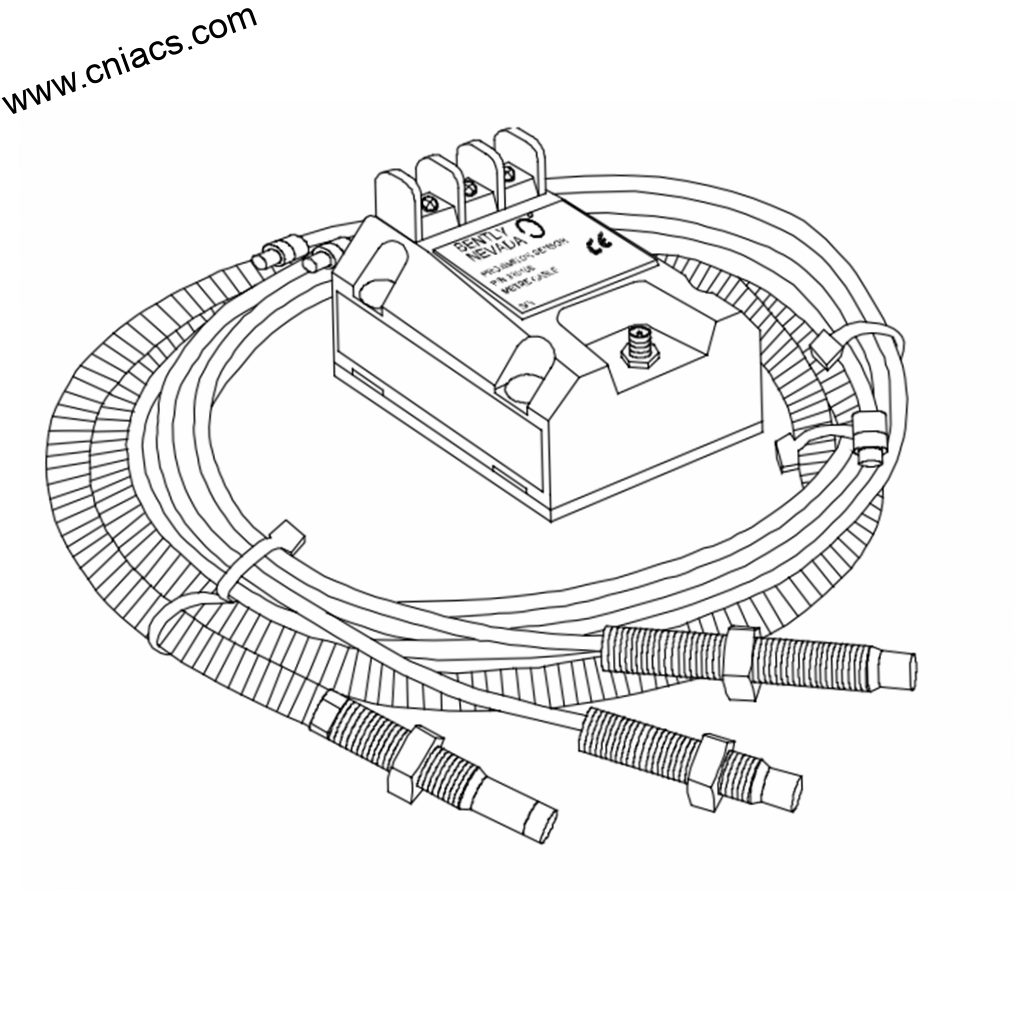

BENTLY Nevada 330930-065-03-05 Cable Extension Module

Introducing the BENTLY Nevada: The Pinnacle of Monitoring and Protection Solutions

In the realm of industrial automation, precision and reliability are paramount. The BENTLY Nevada series, renowned for its state-of-the-art condition monitoring and protection capabilities, stands at the forefront of BENTLY automation products. The BENTLY Nevada model delivers unparalleled performance, ensuring the integrity and efficiency of critical machinery across a variety of sectors.

Key Technical Features

The BENTLY Nevada model is engineered with cutting-edge technology designed to provide comprehensive monitoring of rotating machinery. Its key technical features include:

1. Advanced Vibration Analysis: The BENTLY Nevada integrates sophisticated vibration sensors that capture crucial data, allowing for real-time analysis of machine health. This functionality helps identify potential issues before they escalate into costly failures.

2. Multi-Channel Capability: With the ability to monitor multiple channels simultaneously, the BENTLY Nevada supports extensive data collection from various machinery, making it an ideal choice for complex industrial environments.

3. High Reliability: Designed for harsh operating conditions, it offers robust performance with high tolerance to temperature fluctuations, vibration, and electromagnetic interference, ensuring consistent operation in challenging environments.

4. User-Friendly Interface: The intuitive interface allows for easy navigation and quick access to critical information. Users can effortlessly configure settings, review data, and generate reports, streamlining the monitoring process.

5. Integration Flexibility: The BENTLY Nevada model seamlessly integrates with existing systems, providing compatibility with other BENTLY automation products such as the BENTLY 3500 series and BENTLY 3300 series, thus enhancing overall operational efficiency.

6. Predictive Maintenance Capabilities: By leveraging advanced algorithms, the BENTLY Nevada enables predictive maintenance strategies, allowing organizations to schedule maintenance activities based on actual machine condition rather than fixed intervals, thereby reducing downtime and maintenance costs.

Usage Scenarios

The versatility of the BENTLY Nevada model makes it suitable for a wide range of industrial applications. Some key usage scenarios include:

– Power Generation: In power plants, where machinery reliability is critical, the BENTLY Nevada ensures optimal performance of turbines, generators, and auxiliary systems, minimizing unplanned outages and maximizing efficiency.

– Oil and Gas: The model is indispensable in the oil and gas industry for monitoring pumps, compressors, and turbines, where early detection of anomalies can prevent environmental hazards and costly repairs.

– Manufacturing: In manufacturing facilities, the BENTLY Nevada helps maintain the integrity of critical equipment such as CNC machines and conveyors

The above parameters are for reference only. Please contact our technical team for precise selection.

In the realm of industrial automation, precision and reliability are paramount. The BENTLY Nevada series, renowned for its state-of-the-art condition monitoring and protection capabilities, stands at the forefront of BENTLY automation products. The BENTLY Nevada model delivers unparalleled performance, ensuring the integrity and efficiency of critical machinery across a variety of sectors.

Key Technical Features

The BENTLY Nevada model is engineered with cutting-edge technology designed to provide comprehensive monitoring of rotating machinery. Its key technical features include:

1. Advanced Vibration Analysis: The BENTLY Nevada integrates sophisticated vibration sensors that capture crucial data, allowing for real-time analysis of machine health. This functionality helps identify potential issues before they escalate into costly failures.

2. Multi-Channel Capability: With the ability to monitor multiple channels simultaneously, the BENTLY Nevada supports extensive data collection from various machinery, making it an ideal choice for complex industrial environments.

3. High Reliability: Designed for harsh operating conditions, it offers robust performance with high tolerance to temperature fluctuations, vibration, and electromagnetic interference, ensuring consistent operation in challenging environments.

4. User-Friendly Interface: The intuitive interface allows for easy navigation and quick access to critical information. Users can effortlessly configure settings, review data, and generate reports, streamlining the monitoring process.

5. Integration Flexibility: The BENTLY Nevada model seamlessly integrates with existing systems, providing compatibility with other BENTLY automation products such as the BENTLY 3500 series and BENTLY 3300 series, thus enhancing overall operational efficiency.

6. Predictive Maintenance Capabilities: By leveraging advanced algorithms, the BENTLY Nevada enables predictive maintenance strategies, allowing organizations to schedule maintenance activities based on actual machine condition rather than fixed intervals, thereby reducing downtime and maintenance costs.

Usage Scenarios

The versatility of the BENTLY Nevada model makes it suitable for a wide range of industrial applications. Some key usage scenarios include:

– Power Generation: In power plants, where machinery reliability is critical, the BENTLY Nevada ensures optimal performance of turbines, generators, and auxiliary systems, minimizing unplanned outages and maximizing efficiency.

– Oil and Gas: The model is indispensable in the oil and gas industry for monitoring pumps, compressors, and turbines, where early detection of anomalies can prevent environmental hazards and costly repairs.

– Manufacturing: In manufacturing facilities, the BENTLY Nevada helps maintain the integrity of critical equipment such as CNC machines and conveyors

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.png?v=1739321142)

There are no reviews yet.