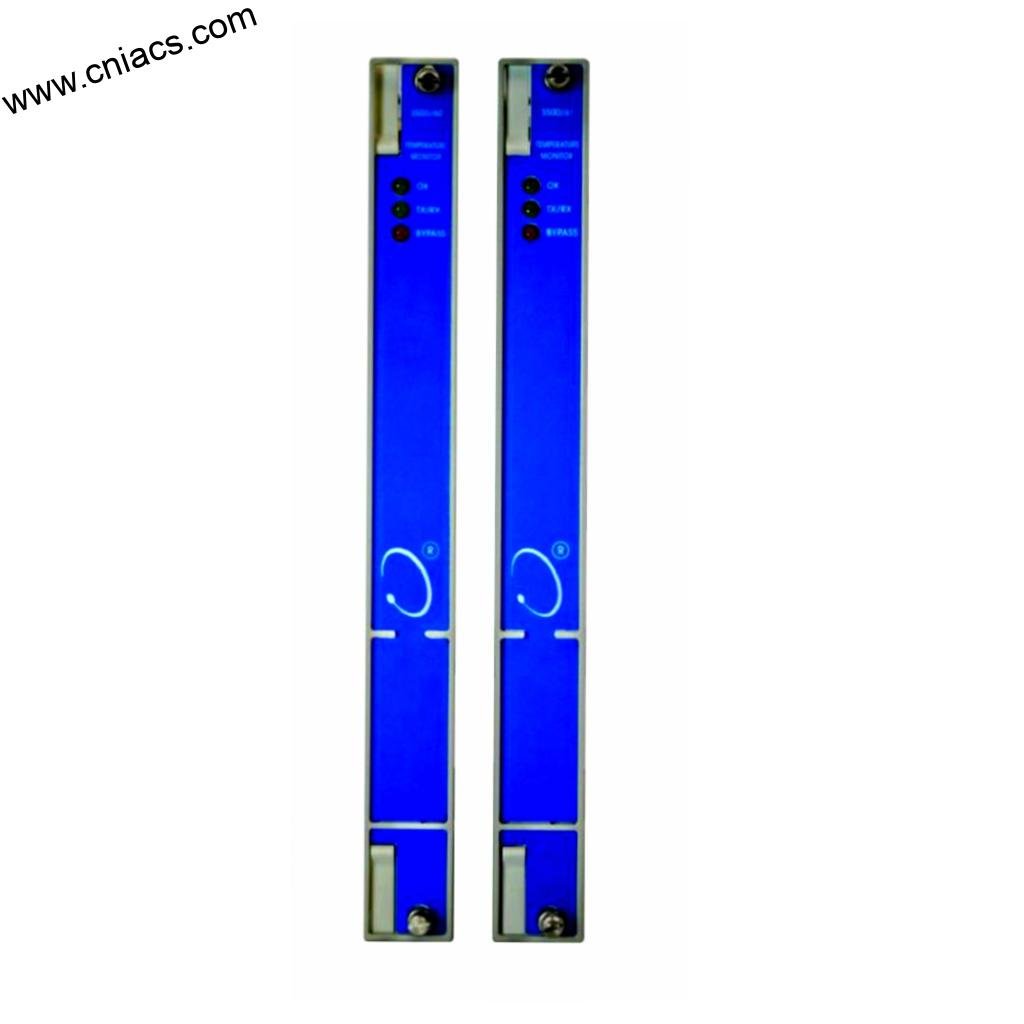

BENTLY Nevada 3500/25 126398-01H Keyphasor Module

Introducing the BENTLY Nevada: the pinnacle of reliability in industrial monitoring and automation solutions. As part of BENTLY’s esteemed range of automation products, the BENTLY Nevada series is engineered to deliver precise performance monitoring, ensuring the integrity and efficiency of your machinery. With a robust set of technical features and versatile applications, this model stands out as an essential tool for industries that prioritize operational excellence.

### Key Technical Features

The BENTLY Nevada model is equipped with advanced technology designed for superior performance in vibration monitoring and machinery protection. Key features include:

1. **High-Resolution Data Acquisition**: With a sampling rate of up to 50 kHz, the BENTLY Nevada captures data with exceptional precision, allowing for detailed analysis and early detection of potential issues.

2. **Wide Operating Temperature Range**: This model is built to perform optimally in harsh environments, operating effectively across a wide temperature range of -40°C to +85°C (-40°F to +185°F).

3. **Robust Communication Protocols**: BENTLY Nevada supports multiple communication protocols, including Ethernet, Modbus, and TCP/IP, ensuring seamless integration into existing industrial networks.

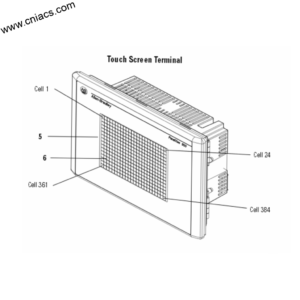

4. **User-Friendly Interface**: The intuitive interface allows for easy navigation and configuration, enabling users to set up monitoring parameters and access real-time data quickly.

5. **Comprehensive Diagnostic Tools**: Equipped with built-in diagnostic capabilities, the BENTLY Nevada provides actionable insights into machine health, helping to prevent unexpected downtime and extend machinery lifespan.

6. **Modular Design**: The modular architecture allows for easy upgrades and scalability, making it adaptable to the evolving needs of your operations.

### Usage Scenarios

The BENTLY Nevada is ideal for various industrial applications, particularly in sectors where machine reliability and performance are critical. Common usage scenarios include:

– **Power Generation**: In power plants, the BENTLY Nevada monitors critical components like turbines and generators, ensuring they operate efficiently and safely.

– **Oil and Gas**: In the oil and gas sector, real-time monitoring of rotating equipment, such as compressors and pumps, is crucial. The BENTLY Nevada provides the insights necessary to mitigate risks and optimize performance.

– **Manufacturing**: In manufacturing facilities, this model enhances production line reliability by monitoring machinery health, enabling predictive maintenance strategies.

– **Mining**: The harsh conditions of mining operations require robust monitoring solutions. The BENTLY Nevada excels in these environments, providing essential data to

The above parameters are for reference only. Please contact our technical team for precise selection.

### Key Technical Features

The BENTLY Nevada model is equipped with advanced technology designed for superior performance in vibration monitoring and machinery protection. Key features include:

1. **High-Resolution Data Acquisition**: With a sampling rate of up to 50 kHz, the BENTLY Nevada captures data with exceptional precision, allowing for detailed analysis and early detection of potential issues.

2. **Wide Operating Temperature Range**: This model is built to perform optimally in harsh environments, operating effectively across a wide temperature range of -40°C to +85°C (-40°F to +185°F).

3. **Robust Communication Protocols**: BENTLY Nevada supports multiple communication protocols, including Ethernet, Modbus, and TCP/IP, ensuring seamless integration into existing industrial networks.

4. **User-Friendly Interface**: The intuitive interface allows for easy navigation and configuration, enabling users to set up monitoring parameters and access real-time data quickly.

5. **Comprehensive Diagnostic Tools**: Equipped with built-in diagnostic capabilities, the BENTLY Nevada provides actionable insights into machine health, helping to prevent unexpected downtime and extend machinery lifespan.

6. **Modular Design**: The modular architecture allows for easy upgrades and scalability, making it adaptable to the evolving needs of your operations.

### Usage Scenarios

The BENTLY Nevada is ideal for various industrial applications, particularly in sectors where machine reliability and performance are critical. Common usage scenarios include:

– **Power Generation**: In power plants, the BENTLY Nevada monitors critical components like turbines and generators, ensuring they operate efficiently and safely.

– **Oil and Gas**: In the oil and gas sector, real-time monitoring of rotating equipment, such as compressors and pumps, is crucial. The BENTLY Nevada provides the insights necessary to mitigate risks and optimize performance.

– **Manufacturing**: In manufacturing facilities, this model enhances production line reliability by monitoring machinery health, enabling predictive maintenance strategies.

– **Mining**: The harsh conditions of mining operations require robust monitoring solutions. The BENTLY Nevada excels in these environments, providing essential data to

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.jpg?v=1739237723)

There are no reviews yet.