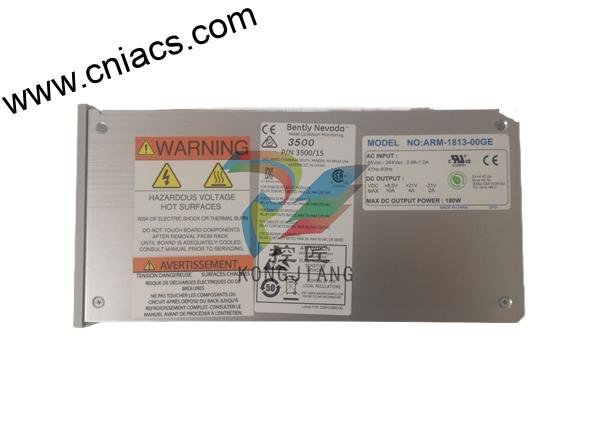

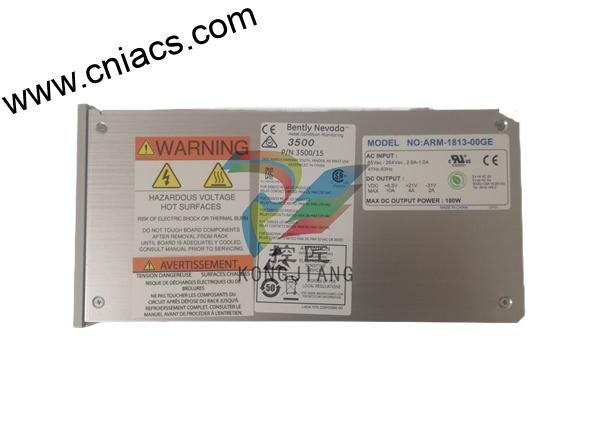

BENTLY Nevada 3500/65 Module for Advanced Control Systems

Introducing the BENTLY Nevada 3500/65: Your Premier Choice for Vibration Monitoring and Machine Protection

In the world of industrial automation and machine health management, the BENTLY Nevada 3500/65 stands out as a top-tier solution, designed for optimal performance and reliability. This advanced monitoring system is part of the BENTLY automation products family, renowned for their precision and effectiveness in safeguarding critical machinery. The 3500/65 model combines innovative technology with user-friendly features, making it an essential component for industries that prioritize operational efficiency and equipment longevity.

Key Technical Features

The BENTLY Nevada 3500/65 is engineered with cutting-edge technology that provides comprehensive monitoring capabilities. Its key features include:

1. **Advanced Vibration Analysis**: The 3500/65 offers high-resolution vibration monitoring, allowing for real-time data acquisition and analysis. This ensures that any deviations from normal operational parameters are detected promptly, enabling proactive maintenance.

2. **Flexibility and Scalability**: One of the standout features of the 3500/65 is its modular design, which allows it to integrate seamlessly with existing BENTLY systems. It can be easily expanded to accommodate additional sensors, making it a versatile choice for any industrial environment.

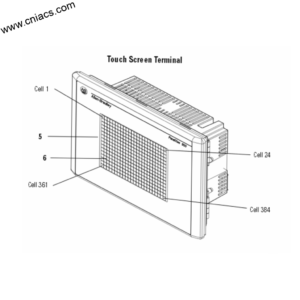

3. **User-Friendly Interface**: The model includes an intuitive interface that simplifies configuration and monitoring. Users can easily access critical data and diagnostics, enhancing operational efficiency.

4. **Robust Data Logging**: The 3500/65 is equipped with extensive data logging capabilities, allowing users to track historical performance metrics. This feature is invaluable for identifying trends, conducting root cause analysis, and improving overall machine reliability.

5. **Compatibility**: The BENTLY Nevada 3500/65 is designed to work with a wide array of sensors and accessories, making it compatible with various industrial applications and environments.

Usage Scenarios

The BENTLY Nevada 3500/65 is ideal for various industries, including manufacturing, oil and gas, power generation, and water treatment. Its versatility makes it suitable for monitoring a range of machinery, such as:

– **Rotating Equipment**: This includes pumps, turbines, and compressors, where precision monitoring is crucial for preventing failures and optimizing performance.

– **Heavy Machinery**: In environments where large equipment operates under extreme conditions, the 3500/65 provides the necessary insights to ensure that machinery remains within safe operational limits.

– **Process Plants**: For facilities that rely on continuous

The above parameters are for reference only. Please contact our technical team for precise selection.

In the world of industrial automation and machine health management, the BENTLY Nevada 3500/65 stands out as a top-tier solution, designed for optimal performance and reliability. This advanced monitoring system is part of the BENTLY automation products family, renowned for their precision and effectiveness in safeguarding critical machinery. The 3500/65 model combines innovative technology with user-friendly features, making it an essential component for industries that prioritize operational efficiency and equipment longevity.

Key Technical Features

The BENTLY Nevada 3500/65 is engineered with cutting-edge technology that provides comprehensive monitoring capabilities. Its key features include:

1. **Advanced Vibration Analysis**: The 3500/65 offers high-resolution vibration monitoring, allowing for real-time data acquisition and analysis. This ensures that any deviations from normal operational parameters are detected promptly, enabling proactive maintenance.

2. **Flexibility and Scalability**: One of the standout features of the 3500/65 is its modular design, which allows it to integrate seamlessly with existing BENTLY systems. It can be easily expanded to accommodate additional sensors, making it a versatile choice for any industrial environment.

3. **User-Friendly Interface**: The model includes an intuitive interface that simplifies configuration and monitoring. Users can easily access critical data and diagnostics, enhancing operational efficiency.

4. **Robust Data Logging**: The 3500/65 is equipped with extensive data logging capabilities, allowing users to track historical performance metrics. This feature is invaluable for identifying trends, conducting root cause analysis, and improving overall machine reliability.

5. **Compatibility**: The BENTLY Nevada 3500/65 is designed to work with a wide array of sensors and accessories, making it compatible with various industrial applications and environments.

Usage Scenarios

The BENTLY Nevada 3500/65 is ideal for various industries, including manufacturing, oil and gas, power generation, and water treatment. Its versatility makes it suitable for monitoring a range of machinery, such as:

– **Rotating Equipment**: This includes pumps, turbines, and compressors, where precision monitoring is crucial for preventing failures and optimizing performance.

– **Heavy Machinery**: In environments where large equipment operates under extreme conditions, the 3500/65 provides the necessary insights to ensure that machinery remains within safe operational limits.

– **Process Plants**: For facilities that rely on continuous

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.