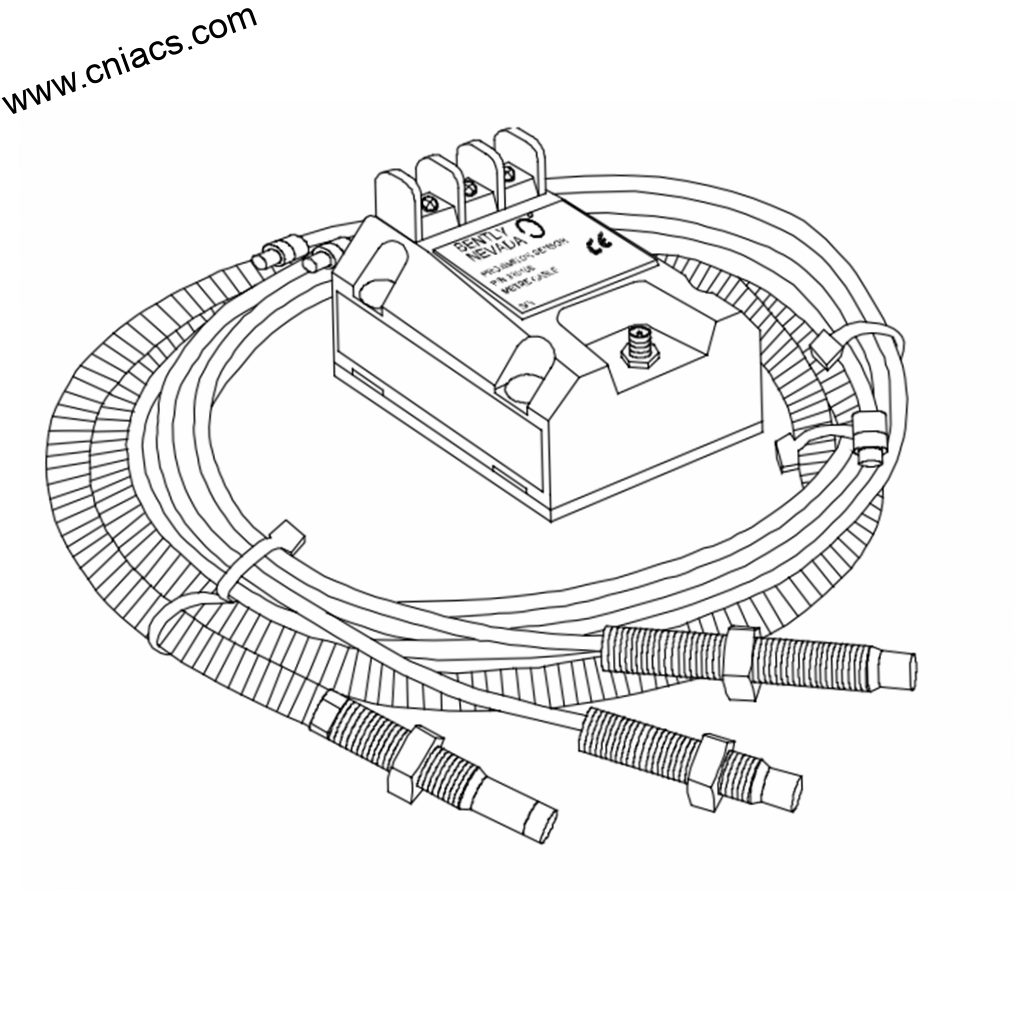

BENTLY Nevada 400100-100-02 Proximitor Sensor, Advanced Industrial Monitoring Solution

Introducing the BENTLY Nevada – The Pinnacle of Precision Monitoring and Protection

In the world of industrial automation and machinery health monitoring, BENTLY Nevada stands out as a trusted name synonymous with reliability, innovation, and excellence. The BENTLY Nevada system embodies cutting-edge technology and unparalleled performance, making it an essential tool for industries that demand precision and efficiency. With a wide range of features tailored to meet the needs of various applications, the BENTLY Nevada is engineered to optimize performance and reduce downtime.

Key Technical Features

The BENTLY Nevada system offers an impressive array of technical features designed to deliver precise monitoring and protection for rotating machinery. Key highlights include:

1. **Advanced Vibration Monitoring**: The BENTLY Nevada system employs state-of-the-art vibration sensors that provide real-time data on machinery health. This enables operators to detect anomalies early, preventing potential failures.

2. **Comprehensive Data Acquisition**: With the ability to collect and analyze data from multiple sensors simultaneously, the BENTLY Nevada ensures that you have a complete picture of your equipment's performance. This is essential for proactive maintenance and operational efficiency.

3. **User-Friendly Interface**: The intuitive graphical user interface makes it easy for operators to navigate the system and interpret data quickly. This user-centric design enhances operational efficiency and minimizes training time for new users.

4. **Scalability**: Whether you are monitoring a single machine or an entire fleet, the BENTLY Nevada system is highly scalable. It can be easily expanded to accommodate additional sensors and monitoring points, allowing for flexibility as your needs evolve.

5. **Integration with BENTLY Automation Products**: The BENTLY Nevada system seamlessly integrates with other BENTLY automation products, creating a comprehensive monitoring solution that enhances reliability and performance across your operations.

Usage Scenarios

The versatility of the BENTLY Nevada system makes it suitable for a wide range of industrial applications. Common usage scenarios include:

– **Power Generation**: In power plants, the BENTLY Nevada system monitors turbines, generators, and other critical equipment to ensure optimal performance and prevent unplanned outages.

– **Oil and Gas**: In the oil and gas industry, where equipment reliability is paramount, the BENTLY Nevada system provides real-time monitoring of pumps, compressors, and other rotating machinery to enhance safety and efficiency.

– **Manufacturing**: In manufacturing settings, the BENTLY Nevada system helps monitor equipment such as motors, fans, and conveyors,

The above parameters are for reference only. Please contact our technical team for precise selection.

In the world of industrial automation and machinery health monitoring, BENTLY Nevada stands out as a trusted name synonymous with reliability, innovation, and excellence. The BENTLY Nevada system embodies cutting-edge technology and unparalleled performance, making it an essential tool for industries that demand precision and efficiency. With a wide range of features tailored to meet the needs of various applications, the BENTLY Nevada is engineered to optimize performance and reduce downtime.

Key Technical Features

The BENTLY Nevada system offers an impressive array of technical features designed to deliver precise monitoring and protection for rotating machinery. Key highlights include:

1. **Advanced Vibration Monitoring**: The BENTLY Nevada system employs state-of-the-art vibration sensors that provide real-time data on machinery health. This enables operators to detect anomalies early, preventing potential failures.

2. **Comprehensive Data Acquisition**: With the ability to collect and analyze data from multiple sensors simultaneously, the BENTLY Nevada ensures that you have a complete picture of your equipment's performance. This is essential for proactive maintenance and operational efficiency.

3. **User-Friendly Interface**: The intuitive graphical user interface makes it easy for operators to navigate the system and interpret data quickly. This user-centric design enhances operational efficiency and minimizes training time for new users.

4. **Scalability**: Whether you are monitoring a single machine or an entire fleet, the BENTLY Nevada system is highly scalable. It can be easily expanded to accommodate additional sensors and monitoring points, allowing for flexibility as your needs evolve.

5. **Integration with BENTLY Automation Products**: The BENTLY Nevada system seamlessly integrates with other BENTLY automation products, creating a comprehensive monitoring solution that enhances reliability and performance across your operations.

Usage Scenarios

The versatility of the BENTLY Nevada system makes it suitable for a wide range of industrial applications. Common usage scenarios include:

– **Power Generation**: In power plants, the BENTLY Nevada system monitors turbines, generators, and other critical equipment to ensure optimal performance and prevent unplanned outages.

– **Oil and Gas**: In the oil and gas industry, where equipment reliability is paramount, the BENTLY Nevada system provides real-time monitoring of pumps, compressors, and other rotating machinery to enhance safety and efficiency.

– **Manufacturing**: In manufacturing settings, the BENTLY Nevada system helps monitor equipment such as motors, fans, and conveyors,

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.