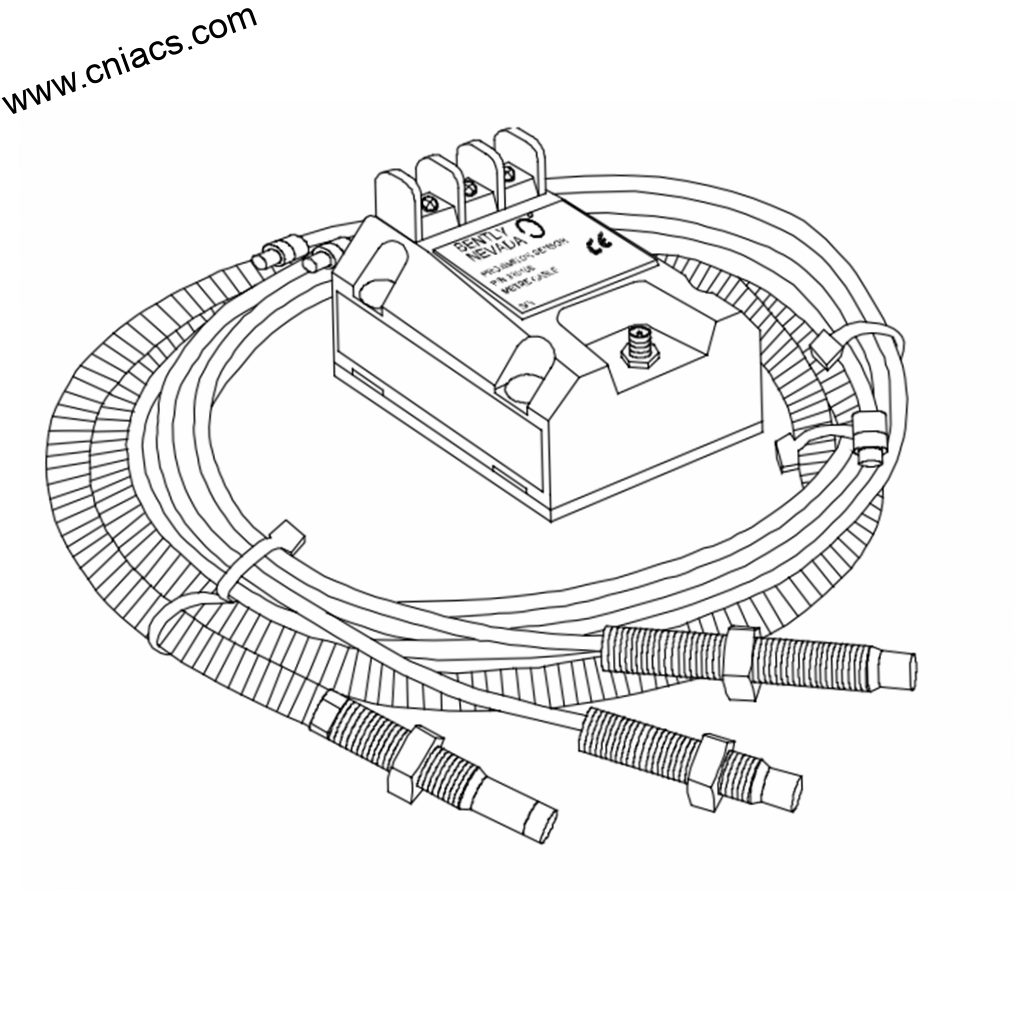

BENTLY Nevada 84661-33 Precision Velomitor Interconnect Cable, Engineered for Industrial Control Applications

Introducing the BENTLY Nevada 84661-33: The Pinnacle of Vibration Monitoring Technology

In the realm of industrial automation, precision and reliability are paramount. The BENTLY Nevada 84661-33 stands out as an exemplary model in BENTLY's esteemed line of automation products, designed to provide unparalleled performance in vibration monitoring and diagnostic capabilities. This advanced system is engineered to facilitate comprehensive condition monitoring, ensuring your critical machinery operates smoothly and efficiently.

Key Technical Features

The BENTLY Nevada 84661-33 is infused with cutting-edge technology that enhances its functionality and reliability. Key features include:

1. **High-Resolution Measurement**: The 84661-33 delivers precise vibration data with advanced algorithms that analyze machine performance in real-time. This high-resolution measurement capability allows for early detection of potential issues, enabling proactive maintenance.

2. **Broad Frequency Range**: Capable of monitoring a wide frequency spectrum, the device is adept at detecting various types of vibration signatures, making it suitable for diverse applications across industries.

3. **Robust Design**: Built to withstand harsh industrial environments, the 84661-33 features a rugged construction that ensures durability and longevity. Its resistance to temperature fluctuations, dust, and moisture makes it an ideal choice for demanding conditions.

4. **User-Friendly Interface**: Equipped with an intuitive interface, the BENTLY Nevada 84661-33 simplifies setup and operation. Users can easily navigate through its features and access vital data quickly, enhancing overall efficiency.

5. **Integration Capabilities**: The device seamlessly integrates with existing BENTLY automation products and other third-party systems, allowing for a cohesive monitoring solution across various machinery.

Usage Scenarios

The versatility of the BENTLY Nevada 84661-33 makes it perfect for a range of industrial applications. Some common usage scenarios include:

1. **Rotating Equipment Monitoring**: Ideal for industries utilizing turbines, pumps, and compressors, the 84661-33 provides critical insights into the health of rotating machinery, helping to minimize downtime and extend equipment life.

2. **Predictive Maintenance**: By continuously monitoring vibration patterns, the BENTLY Nevada 84661-33 allows maintenance teams to implement predictive strategies, reducing unplanned outages and maintenance costs.

3. **Quality Control**: In manufacturing settings, maintaining equipment integrity is crucial. The device ensures that production machinery operates within optimal parameters, thereby enhancing product quality and consistency.

4. **Safety Enhancements**

The above parameters are for reference only. Please contact our technical team for precise selection.

In the realm of industrial automation, precision and reliability are paramount. The BENTLY Nevada 84661-33 stands out as an exemplary model in BENTLY's esteemed line of automation products, designed to provide unparalleled performance in vibration monitoring and diagnostic capabilities. This advanced system is engineered to facilitate comprehensive condition monitoring, ensuring your critical machinery operates smoothly and efficiently.

Key Technical Features

The BENTLY Nevada 84661-33 is infused with cutting-edge technology that enhances its functionality and reliability. Key features include:

1. **High-Resolution Measurement**: The 84661-33 delivers precise vibration data with advanced algorithms that analyze machine performance in real-time. This high-resolution measurement capability allows for early detection of potential issues, enabling proactive maintenance.

2. **Broad Frequency Range**: Capable of monitoring a wide frequency spectrum, the device is adept at detecting various types of vibration signatures, making it suitable for diverse applications across industries.

3. **Robust Design**: Built to withstand harsh industrial environments, the 84661-33 features a rugged construction that ensures durability and longevity. Its resistance to temperature fluctuations, dust, and moisture makes it an ideal choice for demanding conditions.

4. **User-Friendly Interface**: Equipped with an intuitive interface, the BENTLY Nevada 84661-33 simplifies setup and operation. Users can easily navigate through its features and access vital data quickly, enhancing overall efficiency.

5. **Integration Capabilities**: The device seamlessly integrates with existing BENTLY automation products and other third-party systems, allowing for a cohesive monitoring solution across various machinery.

Usage Scenarios

The versatility of the BENTLY Nevada 84661-33 makes it perfect for a range of industrial applications. Some common usage scenarios include:

1. **Rotating Equipment Monitoring**: Ideal for industries utilizing turbines, pumps, and compressors, the 84661-33 provides critical insights into the health of rotating machinery, helping to minimize downtime and extend equipment life.

2. **Predictive Maintenance**: By continuously monitoring vibration patterns, the BENTLY Nevada 84661-33 allows maintenance teams to implement predictive strategies, reducing unplanned outages and maintenance costs.

3. **Quality Control**: In manufacturing settings, maintaining equipment integrity is crucial. The device ensures that production machinery operates within optimal parameters, thereby enhancing product quality and consistency.

4. **Safety Enhancements**

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.png?v=1739321142)

-300x300.jpg?v=1739320885)

There are no reviews yet.