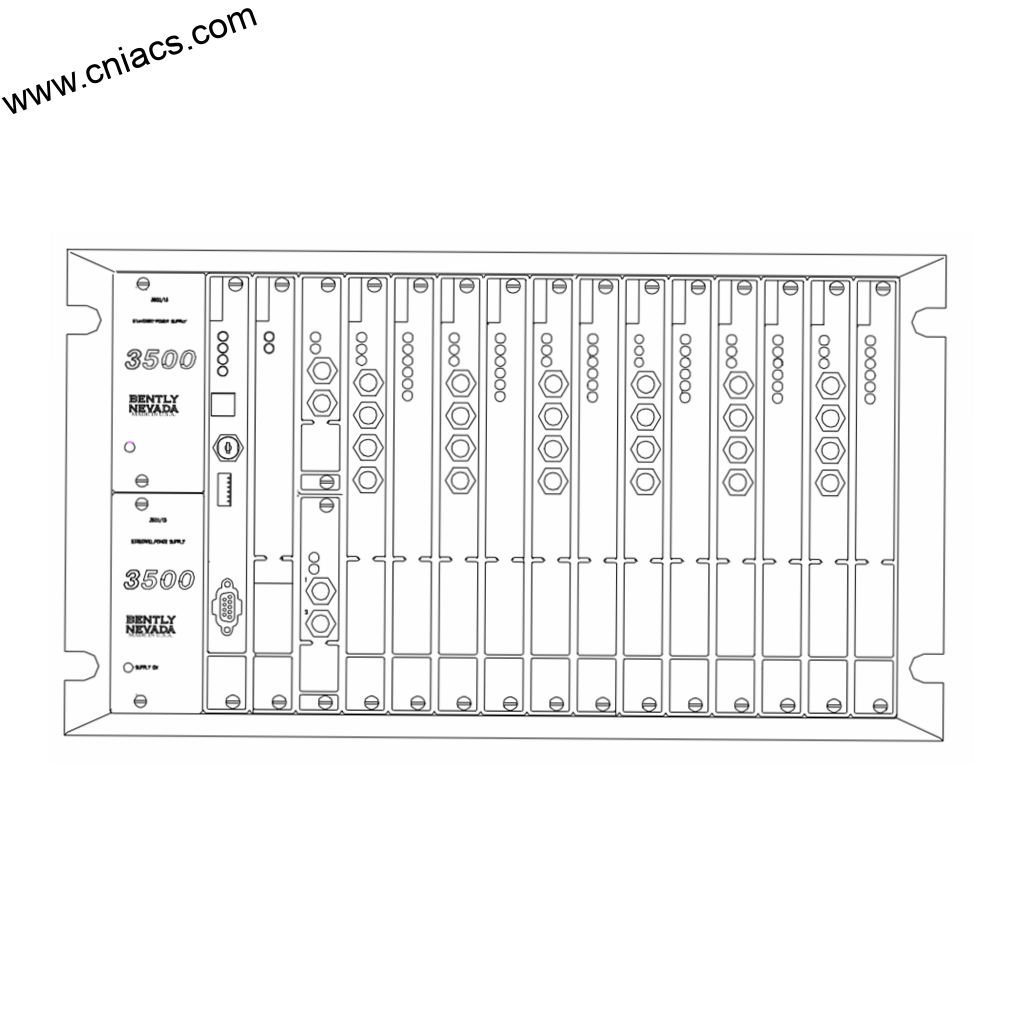

BENTLY Nevada Proximity Sensor 330878-90-00, Advanced Industrial Control Solutions

Introducing the BENTLY Nevada – a pinnacle of precision and reliability in the realm of industrial monitoring and automation. As part of the esteemed BENTLY automation products portfolio, the BENTLY Nevada model combines cutting-edge technology and advanced engineering to offer unmatched performance in condition monitoring applications.

Key Technical Features

The BENTLY Nevada is equipped with state-of-the-art features that set it apart from other models in the BENTLY lineup. It boasts a robust architecture designed for real-time data acquisition and analysis, ensuring that users receive accurate and timely information about their machinery’s health. Key technical features include:

1. **High-Performance Sensors**: The BENTLY Nevada integrates high-fidelity sensors capable of capturing a wide range of vibration and temperature data. This ensures that even the most subtle changes in machine condition can be detected before they lead to failures.

2. **Flexible Communication Options**: With support for various communication protocols, including Ethernet, Modbus, and OPC, the BENTLY Nevada can seamlessly integrate into existing industrial networks, allowing for easy data sharing and remote monitoring.

3. **Scalability**: Designed with flexibility in mind, the system can be scaled to meet the demands of any operation, from small setups to large industrial plants. This adaptability makes it an ideal choice for businesses looking to expand their condition monitoring capabilities.

4. **User-Friendly Interface**: The BENTLY Nevada features an intuitive interface that simplifies setup and operation, enabling users to configure monitoring parameters quickly and effectively without extensive training.

5. **Robust Data Analytics**: Advanced analytics capabilities empower users to conduct in-depth assessments of machinery performance, facilitating proactive maintenance and minimizing downtime.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for various usage scenarios across multiple industries. Whether in power generation, oil and gas, manufacturing, or transportation, this model excels in applications requiring real-time monitoring of rotating equipment. Common scenarios include:

– **Turbine Monitoring**: In power plants, the BENTLY Nevada monitors turbine health, providing critical insights to prevent costly failures and ensure optimal performance.

– **Pump and Compressor Oversight**: For facilities utilizing pumps and compressors, the system allows operators to track vibration levels and detect anomalies, ensuring smooth operation and reducing maintenance costs.

– **Process Optimization**: In manufacturing environments, the BENTLY Nevada aids in optimizing production processes by monitoring equipment performance and identifying inefficiencies.

– **Predictive Maintenance**: By utilizing the advanced

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY Nevada is equipped with state-of-the-art features that set it apart from other models in the BENTLY lineup. It boasts a robust architecture designed for real-time data acquisition and analysis, ensuring that users receive accurate and timely information about their machinery’s health. Key technical features include:

1. **High-Performance Sensors**: The BENTLY Nevada integrates high-fidelity sensors capable of capturing a wide range of vibration and temperature data. This ensures that even the most subtle changes in machine condition can be detected before they lead to failures.

2. **Flexible Communication Options**: With support for various communication protocols, including Ethernet, Modbus, and OPC, the BENTLY Nevada can seamlessly integrate into existing industrial networks, allowing for easy data sharing and remote monitoring.

3. **Scalability**: Designed with flexibility in mind, the system can be scaled to meet the demands of any operation, from small setups to large industrial plants. This adaptability makes it an ideal choice for businesses looking to expand their condition monitoring capabilities.

4. **User-Friendly Interface**: The BENTLY Nevada features an intuitive interface that simplifies setup and operation, enabling users to configure monitoring parameters quickly and effectively without extensive training.

5. **Robust Data Analytics**: Advanced analytics capabilities empower users to conduct in-depth assessments of machinery performance, facilitating proactive maintenance and minimizing downtime.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for various usage scenarios across multiple industries. Whether in power generation, oil and gas, manufacturing, or transportation, this model excels in applications requiring real-time monitoring of rotating equipment. Common scenarios include:

– **Turbine Monitoring**: In power plants, the BENTLY Nevada monitors turbine health, providing critical insights to prevent costly failures and ensure optimal performance.

– **Pump and Compressor Oversight**: For facilities utilizing pumps and compressors, the system allows operators to track vibration levels and detect anomalies, ensuring smooth operation and reducing maintenance costs.

– **Process Optimization**: In manufacturing environments, the BENTLY Nevada aids in optimizing production processes by monitoring equipment performance and identifying inefficiencies.

– **Predictive Maintenance**: By utilizing the advanced

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.jpg?v=1739320885)

There are no reviews yet.