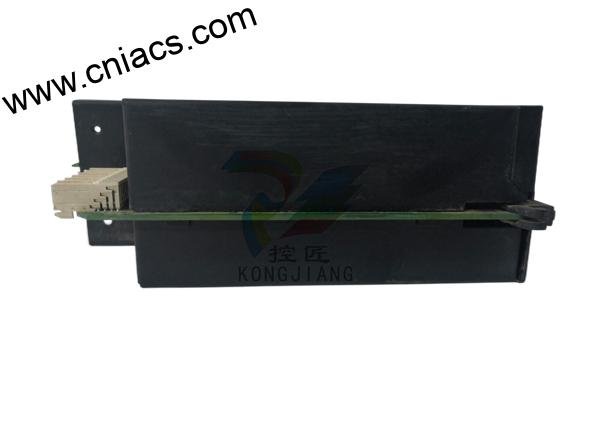

GE FANUC IC670MDL331 High-Performance Field Control I/O Module

Introducing the GE FANUC: The Pinnacle of Industrial Automation Solutions

In the competitive landscape of industrial automation, the GE FANUC stands out as a hallmark of reliability, precision, and innovation. Designed to meet the rigorous demands of modern manufacturing and processing environments, the GE FANUC embodies a robust suite of technical features that facilitate superior control and efficiency.

Key Technical Features

The GE FANUC is engineered with advanced capabilities that position it as a leader in the automation sector. Some of its key technical features include:

1. **High Performance Processing:** Equipped with a powerful processor, the GE FANUC ensures rapid data processing and execution of complex tasks, significantly reducing downtime and improving operational efficiency.

2. **Modular Architecture:** The modular design allows for flexible configuration and scalability, enabling users to customize their systems according to specific operational needs. This adaptability is crucial for industries experiencing fluctuating demands.

3. **Integrated Communication Protocols:** With support for various communication protocols such as Ethernet, Profibus, and more, the GE FANUC facilitates seamless connectivity and integration with other GE automation products and third-party devices, ensuring a cohesive automation ecosystem.

4. **Robust Diagnostic Tools:** The GE FANUC incorporates advanced diagnostic features that provide real-time insights into system performance and health. This capability helps in predictive maintenance, reducing the likelihood of unexpected failures.

5. **High-Quality I/O Modules:** Featuring high-performance input/output modules, the GE FANUC can handle a wide range of analog and digital signals, making it suitable for diverse applications across multiple industries.

6. **User-Friendly Interface:** The intuitive interface allows operators to easily navigate the system, configure settings, and monitor processes. This ease of use reduces training time and enhances operational efficiency.

Usage Scenarios

The versatility of the GE FANUC makes it ideal for a variety of usage scenarios across different industries. Here are some common applications:

– **Manufacturing Automation:** The GE FANUC is widely used in manufacturing plants for controlling robotic systems, conveyor belts, and assembly lines. Its high processing speed and modularity allow for efficient production workflows.

– **Process Control:** In industries such as oil and gas, pharmaceuticals, and food processing, the GE FANUC plays a critical role in monitoring and controlling processes, ensuring safety, compliance, and quality.

– **Building Management Systems:** The GE FANUC is also employed in smart building applications to manage HVAC systems, lighting, and security systems, contributing to energy efficiency and occupant comfort.

– **Energy Management:**

The above parameters are for reference only. Please contact our technical team for precise selection.

In the competitive landscape of industrial automation, the GE FANUC stands out as a hallmark of reliability, precision, and innovation. Designed to meet the rigorous demands of modern manufacturing and processing environments, the GE FANUC embodies a robust suite of technical features that facilitate superior control and efficiency.

Key Technical Features

The GE FANUC is engineered with advanced capabilities that position it as a leader in the automation sector. Some of its key technical features include:

1. **High Performance Processing:** Equipped with a powerful processor, the GE FANUC ensures rapid data processing and execution of complex tasks, significantly reducing downtime and improving operational efficiency.

2. **Modular Architecture:** The modular design allows for flexible configuration and scalability, enabling users to customize their systems according to specific operational needs. This adaptability is crucial for industries experiencing fluctuating demands.

3. **Integrated Communication Protocols:** With support for various communication protocols such as Ethernet, Profibus, and more, the GE FANUC facilitates seamless connectivity and integration with other GE automation products and third-party devices, ensuring a cohesive automation ecosystem.

4. **Robust Diagnostic Tools:** The GE FANUC incorporates advanced diagnostic features that provide real-time insights into system performance and health. This capability helps in predictive maintenance, reducing the likelihood of unexpected failures.

5. **High-Quality I/O Modules:** Featuring high-performance input/output modules, the GE FANUC can handle a wide range of analog and digital signals, making it suitable for diverse applications across multiple industries.

6. **User-Friendly Interface:** The intuitive interface allows operators to easily navigate the system, configure settings, and monitor processes. This ease of use reduces training time and enhances operational efficiency.

Usage Scenarios

The versatility of the GE FANUC makes it ideal for a variety of usage scenarios across different industries. Here are some common applications:

– **Manufacturing Automation:** The GE FANUC is widely used in manufacturing plants for controlling robotic systems, conveyor belts, and assembly lines. Its high processing speed and modularity allow for efficient production workflows.

– **Process Control:** In industries such as oil and gas, pharmaceuticals, and food processing, the GE FANUC plays a critical role in monitoring and controlling processes, ensuring safety, compliance, and quality.

– **Building Management Systems:** The GE FANUC is also employed in smart building applications to manage HVAC systems, lighting, and security systems, contributing to energy efficiency and occupant comfort.

– **Energy Management:**

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.jpg?v=1739237447)

There are no reviews yet.