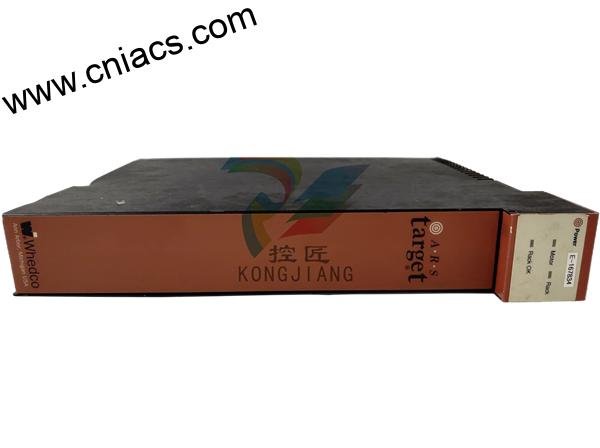

GE Fanuc IC698CPE010JR PAC Systems RX7i Control Module

Introducing the GE Fanuc, a standout in the world of industrial automation, renowned for its reliability, advanced functionality, and seamless integration into a wide variety of applications. This product is designed to meet the demands of modern industries, delivering exceptional performance and cutting-edge technology that enhance operational efficiency and productivity.

### Key Technical Features

The GE Fanuc is equipped with a robust set of technical features that make it a preferred choice for automation solutions. The model boasts a high processing speed, which is crucial for real-time data handling in manufacturing and production environments. With an expansive memory capacity, the GE Fanuc allows for extensive programming, enabling complex automation tasks without compromising performance.

One of the standout features of the GE Fanuc is its versatility in communication protocols. It supports multiple networking options, allowing it to seamlessly integrate with other GE automation products and third-party devices. This feature facilitates flexible system configurations, making it easier to adapt to changing industrial needs.

Additionally, the GE Fanuc incorporates advanced diagnostic tools that aid in troubleshooting and predictive maintenance. These tools help reduce downtime and enhance system reliability, ensuring that operations run smoothly. The model also features a user-friendly interface, simplifying programming and operation for users, regardless of their technical expertise.

### Usage Scenarios

The GE Fanuc is designed for a wide array of applications across various industries. In manufacturing, it plays a pivotal role in automating assembly lines, ensuring precision and efficiency while reducing labor costs. Its ability to handle complex processes makes it ideal for industries such as automotive, consumer goods, and electronics.

In the energy sector, the GE Fanuc is utilized for monitoring and controlling power generation processes. Its robust performance in harsh environments ensures that it can operate effectively in power plants, where reliability is paramount. Additionally, it is used in the oil and gas industry for automation of drilling and extraction processes, ensuring safety and efficiency.

Furthermore, the GE Fanuc is an excellent choice for warehouse automation. Its compatibility with various sensors and robotics allows for streamlined inventory management and logistics operations, significantly improving throughput and accuracy.

### Comparison with Other Models

When compared to other models within the GE brand, such as the GE SR750 and GE IC697MDL740, the GE Fanuc stands out due to its enhanced processing capabilities and broader communication options. While the GE SR750 is known for its advanced motion control features, the GE Fanuc offers a more comprehensive solution for general automation needs, making it suitable for a wider range of applications.

In contrast, models like the GE

The above parameters are for reference only. Please contact our technical team for precise selection.

### Key Technical Features

The GE Fanuc is equipped with a robust set of technical features that make it a preferred choice for automation solutions. The model boasts a high processing speed, which is crucial for real-time data handling in manufacturing and production environments. With an expansive memory capacity, the GE Fanuc allows for extensive programming, enabling complex automation tasks without compromising performance.

One of the standout features of the GE Fanuc is its versatility in communication protocols. It supports multiple networking options, allowing it to seamlessly integrate with other GE automation products and third-party devices. This feature facilitates flexible system configurations, making it easier to adapt to changing industrial needs.

Additionally, the GE Fanuc incorporates advanced diagnostic tools that aid in troubleshooting and predictive maintenance. These tools help reduce downtime and enhance system reliability, ensuring that operations run smoothly. The model also features a user-friendly interface, simplifying programming and operation for users, regardless of their technical expertise.

### Usage Scenarios

The GE Fanuc is designed for a wide array of applications across various industries. In manufacturing, it plays a pivotal role in automating assembly lines, ensuring precision and efficiency while reducing labor costs. Its ability to handle complex processes makes it ideal for industries such as automotive, consumer goods, and electronics.

In the energy sector, the GE Fanuc is utilized for monitoring and controlling power generation processes. Its robust performance in harsh environments ensures that it can operate effectively in power plants, where reliability is paramount. Additionally, it is used in the oil and gas industry for automation of drilling and extraction processes, ensuring safety and efficiency.

Furthermore, the GE Fanuc is an excellent choice for warehouse automation. Its compatibility with various sensors and robotics allows for streamlined inventory management and logistics operations, significantly improving throughput and accuracy.

### Comparison with Other Models

When compared to other models within the GE brand, such as the GE SR750 and GE IC697MDL740, the GE Fanuc stands out due to its enhanced processing capabilities and broader communication options. While the GE SR750 is known for its advanced motion control features, the GE Fanuc offers a more comprehensive solution for general automation needs, making it suitable for a wider range of applications.

In contrast, models like the GE

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.jpg?v=1739237732)

There are no reviews yet.