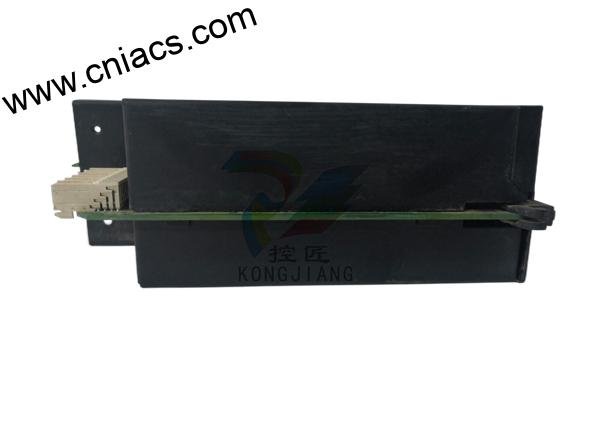

GE PQMII-T20 Industrial Control Module

Introducing the GE PQMII-T20: The Future of Precision Measurement and Control in Automation

In the ever-evolving landscape of industrial automation, precision, reliability, and efficiency are paramount. The GE PQMII-T20 is engineered to meet these demands, offering a sophisticated solution for diverse automation applications. This advanced product is part of GE’s extensive range of automation products, designed to provide unmatched performance in monitoring, controlling, and optimizing processes across various industries.

Key Technical Features

The GE PQMII-T20 is packed with cutting-edge technology that enhances its performance and utility. At its core, this model features high-resolution measurement capabilities, allowing for precise data capture and analysis. The PQMII-T20 supports multiple communication protocols, ensuring seamless integration with existing systems. It is equipped with robust input/output options, enabling users to connect a wide array of sensors and devices, thereby enhancing operational flexibility.

One of the standout features of the PQMII-T20 is its advanced data logging functionality. Users can collect real-time operational data, which can be invaluable for performance analysis and troubleshooting. The unit also comes with intuitive software that simplifies configuration and data visualization, making it easier for operators to interpret data and make informed decisions.

The device is designed for durability, featuring a rugged casing that protects it from harsh industrial environments. It operates effectively in a wide range of temperatures and humidity levels, ensuring consistent performance under varying conditions. Additionally, the PQMII-T20 is compliant with international safety standards, offering peace of mind to users who prioritize safety in their operations.

Usage Scenarios

The versatility of the GE PQMII-T20 makes it suitable for a multitude of applications. In manufacturing environments, it can be used for monitoring machine performance, ensuring optimal operation, and reducing downtime through predictive maintenance. In energy management, the PQMII-T20 can track usage patterns, helping organizations optimize their energy consumption and reduce costs.

In the water and wastewater treatment sector, the PQMII-T20 can monitor critical parameters, such as flow rates and water quality, ensuring compliance with regulatory standards. Its capability to integrate with existing SCADA systems means it can play a crucial role in enhancing control and visibility across the entire process.

Moreover, in the food and beverage industry, the device can be crucial for monitoring temperature and humidity levels during production and storage, thus ensuring product quality and safety. The GE PQMII-T20 is a reliable partner for any industry that demands precision and control.

Comparison with Other Models

When comparing the GE PQMII-T20 to other models in the GE automation products lineup, such as the GE IS200TBCIH1BBC and GE IS220PPROS1B, several key differences emerge. While the IS200TBCIH1BBC is tailored for specialized control applications, the PQMII-T20 offers broader measurement capabilities, making it more versatile for general automation needs.

On the other hand, models like the GE IC697MDL250 and GE IS215UCVEH2AB are primarily focused on I/O management and signal processing. In contrast, the PQMII-T20’s emphasis on data logging and real-time monitoring positions it as a superior choice for applications requiring detailed analytics.

For those considering the GE PQMII-T20, it stands out not only for its technical features but also for its ability to integrate easily with other GE products, such as the GE IS200TPROH1BCB or the GE IC660ELB912G, fostering a comprehensive automation ecosystem.

Reference to Related Models

To further illustrate the capabilities and applications of the GE PQMII-T20, here are ten related models within the GE automation products family:

1. GE IS200TPROH1BCC – A programmable relay ideal for various control applications.

2. GE IS220PRTDH1A – A precision temperature and resistance measurement device.

3. GE 531X307LTBAJG1 – A versatile control board for diverse automation tasks.

4. GE IS200DSPXH1DBC – A digital signal processor for advanced control applications.

5. GE IC693CPU374 – A powerful CPU for handling complex control logic.

6. GE DS200CTBAG1ADD – A communication terminal board that enhances connectivity.

7. GE IS230SNIDH1A – A versatile input/output module designed for flexibility.

8. GE IC670MDL740J – A modular I/O system for adaptable automation setups.

9. GE IC698ACC701 – An advanced accessory for enhancing device capabilities.

10. GE HE693STP110 – A signal processing module for precise control applications.

The GE PQMII-T20 is a testament to GE’s commitment to innovation in automation. Its advanced features, coupled with its adaptability across various industries, make it an essential tool for any organization looking to enhance operational efficiency and precision. Whether you are in manufacturing, energy management, or environmental monitoring, the GE PQMII-T20 is designed to deliver performance and reliability, ensuring that your operations run smoothly and efficiently.

Discover the power of the GE PQMII-T20 and elevate your automation processes to new heights. With its unparalleled performance and integration capabilities, this device is not just a product; it’s a gateway to operational excellence in the world of industrial automation. Embrace the future of precision measurement and control with GE automation products today.

The above parameters are for reference only. Please contact our technical team for precise selection.

In the ever-evolving landscape of industrial automation, precision, reliability, and efficiency are paramount. The GE PQMII-T20 is engineered to meet these demands, offering a sophisticated solution for diverse automation applications. This advanced product is part of GE’s extensive range of automation products, designed to provide unmatched performance in monitoring, controlling, and optimizing processes across various industries.

Key Technical Features

The GE PQMII-T20 is packed with cutting-edge technology that enhances its performance and utility. At its core, this model features high-resolution measurement capabilities, allowing for precise data capture and analysis. The PQMII-T20 supports multiple communication protocols, ensuring seamless integration with existing systems. It is equipped with robust input/output options, enabling users to connect a wide array of sensors and devices, thereby enhancing operational flexibility.

One of the standout features of the PQMII-T20 is its advanced data logging functionality. Users can collect real-time operational data, which can be invaluable for performance analysis and troubleshooting. The unit also comes with intuitive software that simplifies configuration and data visualization, making it easier for operators to interpret data and make informed decisions.

The device is designed for durability, featuring a rugged casing that protects it from harsh industrial environments. It operates effectively in a wide range of temperatures and humidity levels, ensuring consistent performance under varying conditions. Additionally, the PQMII-T20 is compliant with international safety standards, offering peace of mind to users who prioritize safety in their operations.

Usage Scenarios

The versatility of the GE PQMII-T20 makes it suitable for a multitude of applications. In manufacturing environments, it can be used for monitoring machine performance, ensuring optimal operation, and reducing downtime through predictive maintenance. In energy management, the PQMII-T20 can track usage patterns, helping organizations optimize their energy consumption and reduce costs.

In the water and wastewater treatment sector, the PQMII-T20 can monitor critical parameters, such as flow rates and water quality, ensuring compliance with regulatory standards. Its capability to integrate with existing SCADA systems means it can play a crucial role in enhancing control and visibility across the entire process.

Moreover, in the food and beverage industry, the device can be crucial for monitoring temperature and humidity levels during production and storage, thus ensuring product quality and safety. The GE PQMII-T20 is a reliable partner for any industry that demands precision and control.

Comparison with Other Models

When comparing the GE PQMII-T20 to other models in the GE automation products lineup, such as the GE IS200TBCIH1BBC and GE IS220PPROS1B, several key differences emerge. While the IS200TBCIH1BBC is tailored for specialized control applications, the PQMII-T20 offers broader measurement capabilities, making it more versatile for general automation needs.

On the other hand, models like the GE IC697MDL250 and GE IS215UCVEH2AB are primarily focused on I/O management and signal processing. In contrast, the PQMII-T20’s emphasis on data logging and real-time monitoring positions it as a superior choice for applications requiring detailed analytics.

For those considering the GE PQMII-T20, it stands out not only for its technical features but also for its ability to integrate easily with other GE products, such as the GE IS200TPROH1BCB or the GE IC660ELB912G, fostering a comprehensive automation ecosystem.

Reference to Related Models

To further illustrate the capabilities and applications of the GE PQMII-T20, here are ten related models within the GE automation products family:

1. GE IS200TPROH1BCC – A programmable relay ideal for various control applications.

2. GE IS220PRTDH1A – A precision temperature and resistance measurement device.

3. GE 531X307LTBAJG1 – A versatile control board for diverse automation tasks.

4. GE IS200DSPXH1DBC – A digital signal processor for advanced control applications.

5. GE IC693CPU374 – A powerful CPU for handling complex control logic.

6. GE DS200CTBAG1ADD – A communication terminal board that enhances connectivity.

7. GE IS230SNIDH1A – A versatile input/output module designed for flexibility.

8. GE IC670MDL740J – A modular I/O system for adaptable automation setups.

9. GE IC698ACC701 – An advanced accessory for enhancing device capabilities.

10. GE HE693STP110 – A signal processing module for precise control applications.

The GE PQMII-T20 is a testament to GE’s commitment to innovation in automation. Its advanced features, coupled with its adaptability across various industries, make it an essential tool for any organization looking to enhance operational efficiency and precision. Whether you are in manufacturing, energy management, or environmental monitoring, the GE PQMII-T20 is designed to deliver performance and reliability, ensuring that your operations run smoothly and efficiently.

Discover the power of the GE PQMII-T20 and elevate your automation processes to new heights. With its unparalleled performance and integration capabilities, this device is not just a product; it’s a gateway to operational excellence in the world of industrial automation. Embrace the future of precision measurement and control with GE automation products today.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.