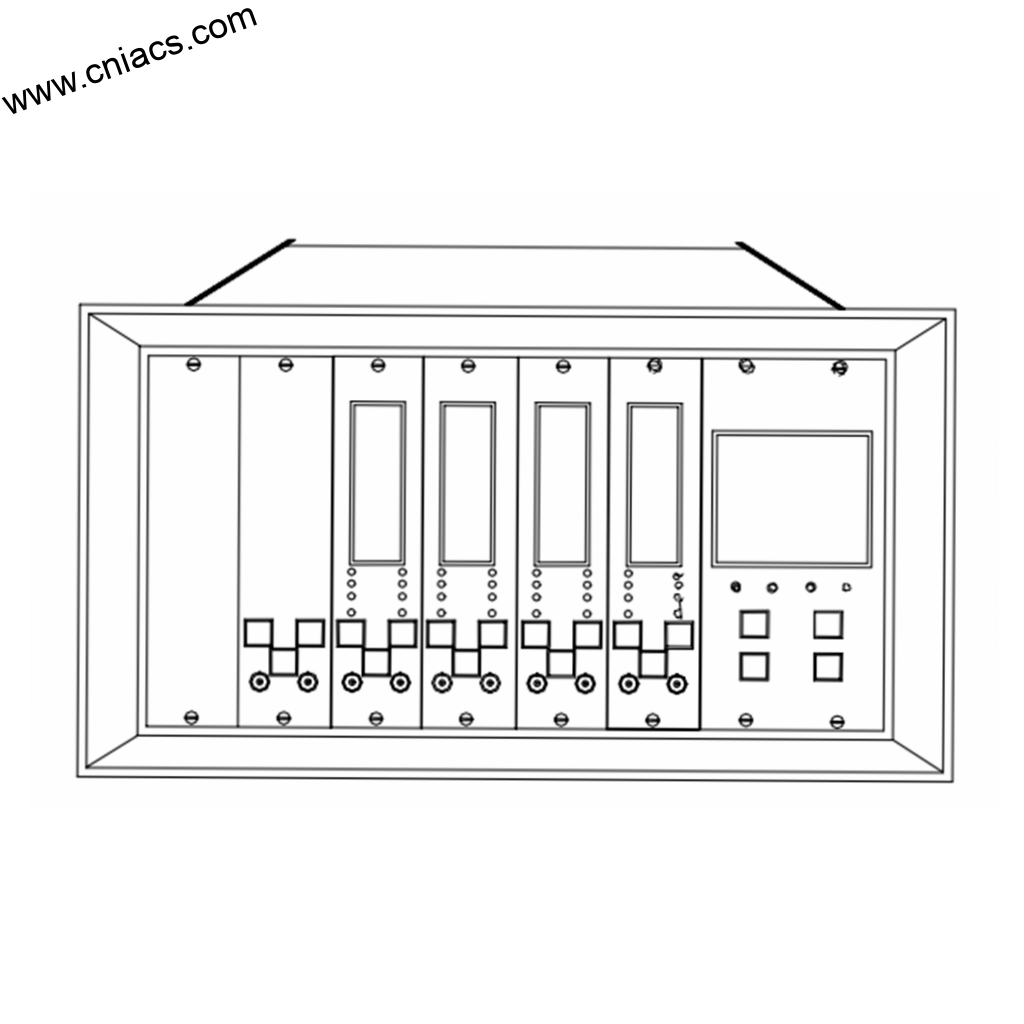

BENTLY 3500/05-01-02-00-00-01 Vibration Monitoring Module

Introducing the BENTLY 3500/05-01-02-00-00-01, a cutting-edge solution in the realm of industrial automation and monitoring. This model is a part of BENTLY's renowned 3500 series, which is celebrated for its precision, reliability, and comprehensive functionality. Designed to meet the highest standards of performance, the BENTLY 3500/05-01-02-00-00-01 stands out as an essential component for any industrial automation setup.

Key Technical Features

At the heart of the BENTLY 3500/05-01-02-00-00-01 are its advanced technical features that enhance monitoring and control capabilities. This model provides unmatched data acquisition and processing, enabling users to make real-time decisions based on accurate information. With its sophisticated signal processing algorithms, it ensures high fidelity in data readings, making it ideal for critical applications.

The BENTLY 3500/05-01-02-00-00-01 is equipped with multiple input channels that allow for a wide range of measurement capabilities, including vibration, temperature, and pressure. The device supports a variety of sensor types, ensuring compatibility with existing infrastructure. Additionally, its robust design ensures durability in harsh environments, allowing it to withstand extreme temperatures, vibrations, and moisture.

One of its standout features is its seamless integration with BENTLY automation products. This model can easily communicate with other devices in the BENTLY ecosystem, enabling users to create a cohesive monitoring and control environment. The user-friendly interface and intuitive software make setup and operation straightforward, reducing the learning curve and enhancing productivity.

Usage Scenarios

The BENTLY 3500/05-01-02-00-00-01 is versatile and can be utilized across various industries, including oil and gas, manufacturing, power generation, and transportation. In oil and gas applications, this model plays a critical role in monitoring the health of machinery, ensuring operational efficiency, and preventing costly downtime. By continuously tracking vibration levels and other key parameters, operators can detect potential issues before they escalate into major failures.

In manufacturing, the BENTLY 3500/05-01-02-00-00-01 aids in optimizing production processes by providing real-time data that can inform operational adjustments. This capability not only enhances productivity but also contributes to overall equipment effectiveness (OEE) by minimizing waste and downtime.

The power generation sector benefits from the BENTLY 3500/

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

At the heart of the BENTLY 3500/05-01-02-00-00-01 are its advanced technical features that enhance monitoring and control capabilities. This model provides unmatched data acquisition and processing, enabling users to make real-time decisions based on accurate information. With its sophisticated signal processing algorithms, it ensures high fidelity in data readings, making it ideal for critical applications.

The BENTLY 3500/05-01-02-00-00-01 is equipped with multiple input channels that allow for a wide range of measurement capabilities, including vibration, temperature, and pressure. The device supports a variety of sensor types, ensuring compatibility with existing infrastructure. Additionally, its robust design ensures durability in harsh environments, allowing it to withstand extreme temperatures, vibrations, and moisture.

One of its standout features is its seamless integration with BENTLY automation products. This model can easily communicate with other devices in the BENTLY ecosystem, enabling users to create a cohesive monitoring and control environment. The user-friendly interface and intuitive software make setup and operation straightforward, reducing the learning curve and enhancing productivity.

Usage Scenarios

The BENTLY 3500/05-01-02-00-00-01 is versatile and can be utilized across various industries, including oil and gas, manufacturing, power generation, and transportation. In oil and gas applications, this model plays a critical role in monitoring the health of machinery, ensuring operational efficiency, and preventing costly downtime. By continuously tracking vibration levels and other key parameters, operators can detect potential issues before they escalate into major failures.

In manufacturing, the BENTLY 3500/05-01-02-00-00-01 aids in optimizing production processes by providing real-time data that can inform operational adjustments. This capability not only enhances productivity but also contributes to overall equipment effectiveness (OEE) by minimizing waste and downtime.

The power generation sector benefits from the BENTLY 3500/

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.png?v=1739321142)

-300x300.jpg?v=1739320885)

There are no reviews yet.