BENTLY 330101-00-20-90-02-05, Proximity Probe for Advanced Industrial Control

Introducing the BENTLY 330101-00-20-90-02-05: A Pinnacle of Precision and Reliability in Condition Monitoring

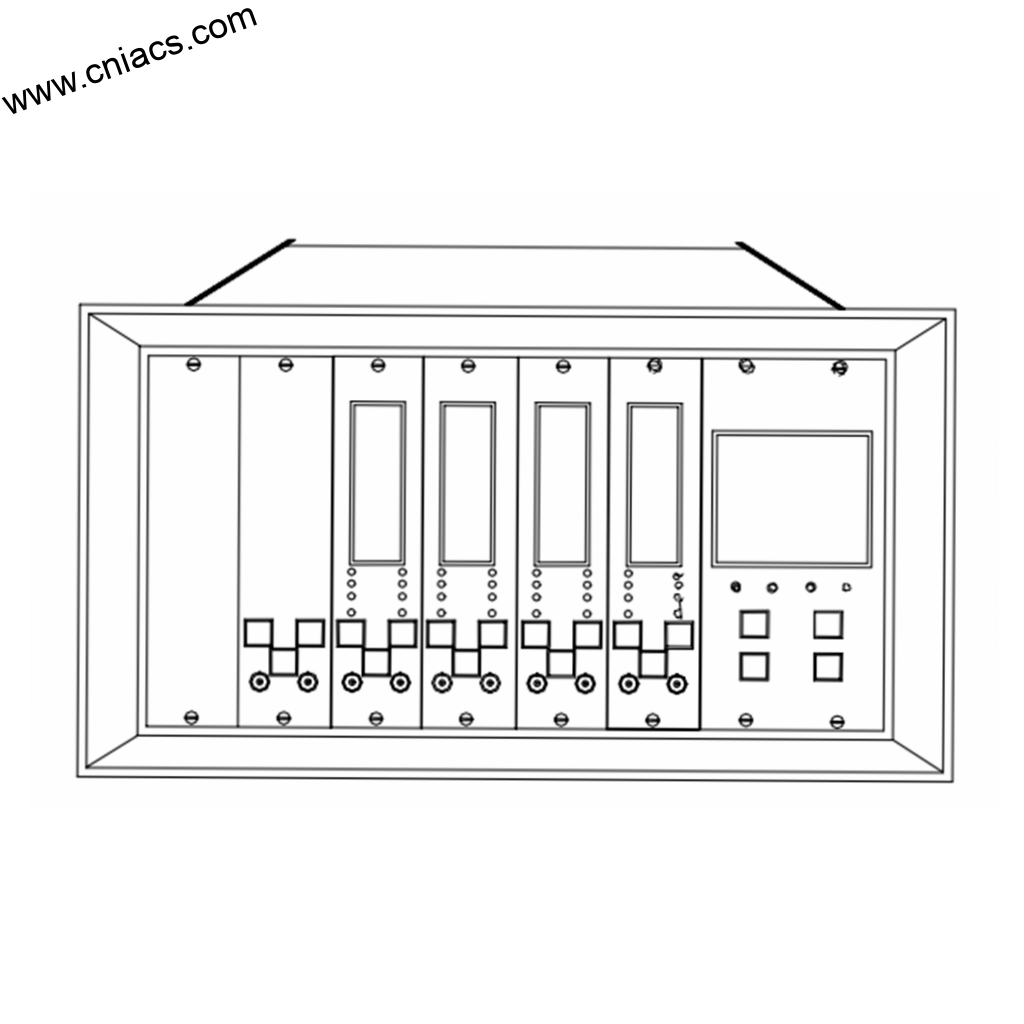

The BENTLY 330101-00-20-90-02-05 is a state-of-the-art condition monitoring system designed to enhance the performance and reliability of industrial machinery. Engineered by BENTLY, a trusted name in automation products, this model stands out with its advanced features and robust design, making it an essential addition to any industrial setup.

Key Technical Features

The BENTLY 330101-00-20-90-02-05 is packed with key technical features that ensure optimal performance. It boasts a high-resolution measurement capability, enabling the precise detection of vibration, temperature, and other critical parameters. With its compatibility with a variety of sensors, the model supports both 4-20 mA and digital communication protocols, providing flexibility for integration into existing systems.

One of the standout features of the BENTLY 330101-00-20-90-02-05 is its advanced signal processing capabilities. The device utilizes sophisticated algorithms to filter out noise and enhance signal clarity, ensuring accurate readings even in challenging environments. Additionally, it offers extensive data logging and reporting functions, allowing users to track performance trends over time and make informed maintenance decisions.

The BENTLY 330101-00-20-90-02-05 also features a user-friendly interface, complete with customizable dashboards and alerts. This allows operators to monitor critical parameters in real-time, ensuring that any anomalies are addressed promptly. Furthermore, the device is built to withstand harsh industrial conditions, with IP65-rated enclosures that protect against dust and moisture.

Usage Scenarios

The versatility of the BENTLY 330101-00-20-90-02-05 makes it suitable for a wide range of applications across various industries. In power generation facilities, it can be deployed to monitor turbine performance, ensuring optimal operation and preventing costly downtime. In the oil and gas sector, the device can track the health of pumps and compressors, enabling predictive maintenance strategies that extend equipment life.

Manufacturers can also benefit from the BENTLY 330101-00-20-90-02-05 by implementing it in their production lines to monitor machinery such as conveyors, mixers, and crushers. By utilizing this condition monitoring system, businesses can reduce unexpected failures, enhance productivity, and maintain a competitive edge in the market.

Moreover, the BENTLY

The above parameters are for reference only. Please contact our technical team for precise selection.

The BENTLY 330101-00-20-90-02-05 is a state-of-the-art condition monitoring system designed to enhance the performance and reliability of industrial machinery. Engineered by BENTLY, a trusted name in automation products, this model stands out with its advanced features and robust design, making it an essential addition to any industrial setup.

Key Technical Features

The BENTLY 330101-00-20-90-02-05 is packed with key technical features that ensure optimal performance. It boasts a high-resolution measurement capability, enabling the precise detection of vibration, temperature, and other critical parameters. With its compatibility with a variety of sensors, the model supports both 4-20 mA and digital communication protocols, providing flexibility for integration into existing systems.

One of the standout features of the BENTLY 330101-00-20-90-02-05 is its advanced signal processing capabilities. The device utilizes sophisticated algorithms to filter out noise and enhance signal clarity, ensuring accurate readings even in challenging environments. Additionally, it offers extensive data logging and reporting functions, allowing users to track performance trends over time and make informed maintenance decisions.

The BENTLY 330101-00-20-90-02-05 also features a user-friendly interface, complete with customizable dashboards and alerts. This allows operators to monitor critical parameters in real-time, ensuring that any anomalies are addressed promptly. Furthermore, the device is built to withstand harsh industrial conditions, with IP65-rated enclosures that protect against dust and moisture.

Usage Scenarios

The versatility of the BENTLY 330101-00-20-90-02-05 makes it suitable for a wide range of applications across various industries. In power generation facilities, it can be deployed to monitor turbine performance, ensuring optimal operation and preventing costly downtime. In the oil and gas sector, the device can track the health of pumps and compressors, enabling predictive maintenance strategies that extend equipment life.

Manufacturers can also benefit from the BENTLY 330101-00-20-90-02-05 by implementing it in their production lines to monitor machinery such as conveyors, mixers, and crushers. By utilizing this condition monitoring system, businesses can reduce unexpected failures, enhance productivity, and maintain a competitive edge in the market.

Moreover, the BENTLY

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.