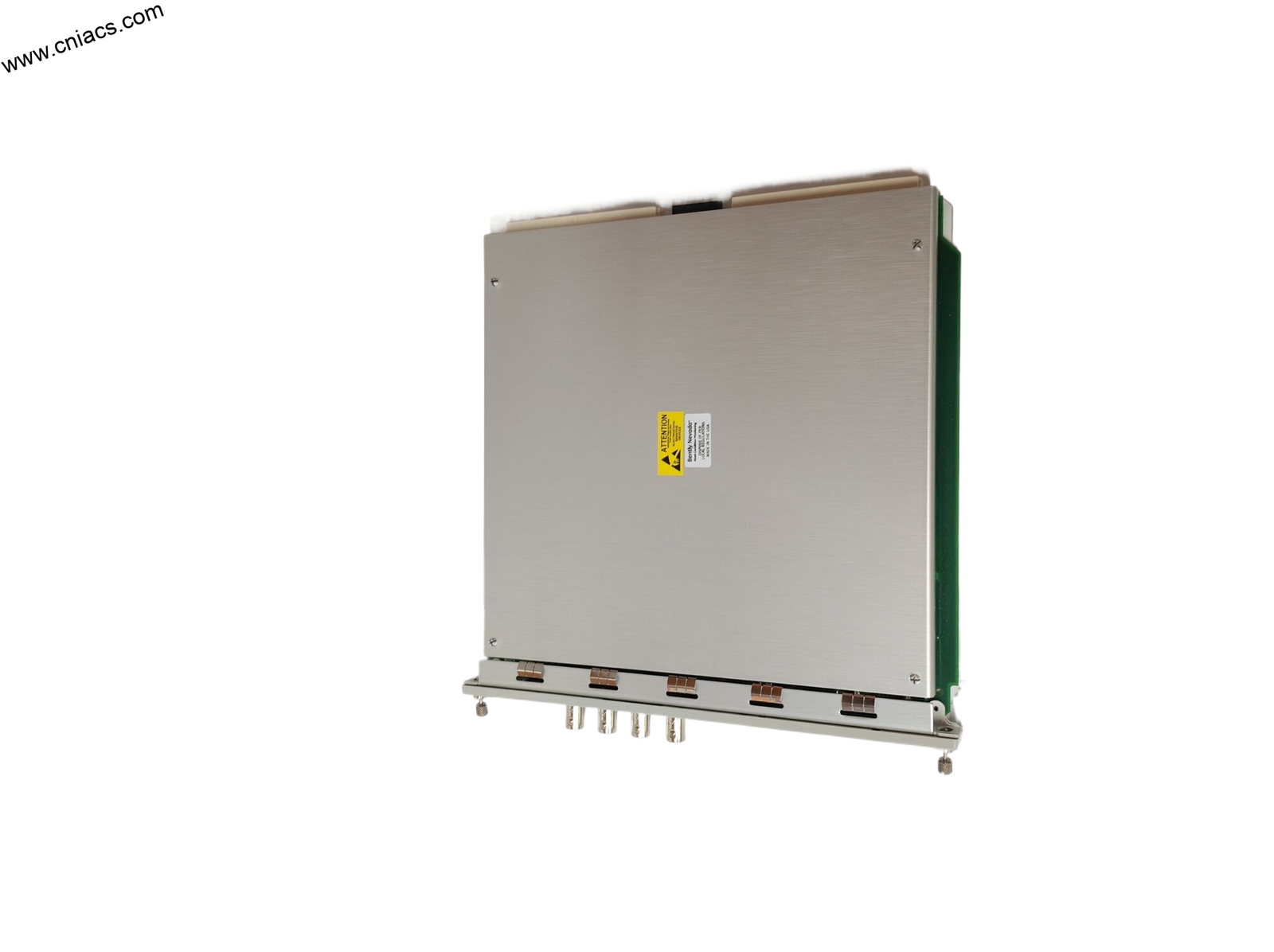

BENTLY 330103-01-07-05-02-00 3300 XL 8 mm Proximity Probes

.png)

Introducing the BENTLY 330103-01-07-05-02-00, a sophisticated and reliable solution in the realm of industrial automation and monitoring. This model is engineered to deliver precise measurement and monitoring capabilities, making it an essential component in various industrial applications. With a focus on performance, durability, and integration, the BENTLY 330103-01-07-05-02-00 stands out as a top choice for businesses looking to enhance their operational efficiency.

**Key Technical Features:**

The BENTLY 330103-01-07-05-02-00 is equipped with advanced features designed to maximize its functionality in demanding environments. It boasts high-resolution data acquisition, ensuring accurate readings for vibration, temperature, and other critical parameters. This model is compatible with a range of sensors, allowing for flexible installation and integration into existing systems.

One of the standout features of the BENTLY 330103-01-07-05-02-00 is its robust communication capabilities. It supports industry-standard protocols, enabling seamless integration with various BENTLY automation products and third-party systems. This not only enhances interoperability but also simplifies data sharing and analysis across platforms.

Furthermore, the BENTLY 330103-01-07-05-02-00 is designed for reliability in harsh environments. With an IP rating that ensures protection against dust and moisture, it can withstand the rigors of industrial settings. The unit is also built with high-quality materials that resist wear and tear, providing a long service life and reducing maintenance costs.

**Usage Scenarios:**

The BENTLY 330103-01-07-05-02-00 is versatile and can be employed in various industries including oil and gas, power generation, and manufacturing. In the oil and gas sector, it is used for monitoring the health of rotating machinery, ensuring that equipment operates within safe limits and preventing costly downtime. In power generation, the model plays a critical role in supervising turbine performance, allowing for early detection of potential failures.

Moreover, in manufacturing environments, the BENTLY 330103-01-07-05-02-00 assists in ensuring that machinery operates efficiently by providing real-time data that can be analyzed for performance optimization. By leveraging its capabilities, industries can enhance predictive maintenance strategies, leading to increased productivity and reduced operational risks.

**Comparison with Other Models:**

When compared to other models within the BENTLY product line, such as the BENTLY

The above parameters are for reference only. Please contact our technical team for precise selection.

**Key Technical Features:**

The BENTLY 330103-01-07-05-02-00 is equipped with advanced features designed to maximize its functionality in demanding environments. It boasts high-resolution data acquisition, ensuring accurate readings for vibration, temperature, and other critical parameters. This model is compatible with a range of sensors, allowing for flexible installation and integration into existing systems.

One of the standout features of the BENTLY 330103-01-07-05-02-00 is its robust communication capabilities. It supports industry-standard protocols, enabling seamless integration with various BENTLY automation products and third-party systems. This not only enhances interoperability but also simplifies data sharing and analysis across platforms.

Furthermore, the BENTLY 330103-01-07-05-02-00 is designed for reliability in harsh environments. With an IP rating that ensures protection against dust and moisture, it can withstand the rigors of industrial settings. The unit is also built with high-quality materials that resist wear and tear, providing a long service life and reducing maintenance costs.

**Usage Scenarios:**

The BENTLY 330103-01-07-05-02-00 is versatile and can be employed in various industries including oil and gas, power generation, and manufacturing. In the oil and gas sector, it is used for monitoring the health of rotating machinery, ensuring that equipment operates within safe limits and preventing costly downtime. In power generation, the model plays a critical role in supervising turbine performance, allowing for early detection of potential failures.

Moreover, in manufacturing environments, the BENTLY 330103-01-07-05-02-00 assists in ensuring that machinery operates efficiently by providing real-time data that can be analyzed for performance optimization. By leveraging its capabilities, industries can enhance predictive maintenance strategies, leading to increased productivity and reduced operational risks.

**Comparison with Other Models:**

When compared to other models within the BENTLY product line, such as the BENTLY

The above parameters are for reference only. Please contact our technical team for precise selection.

.png?v=1739321128)

There are no reviews yet.