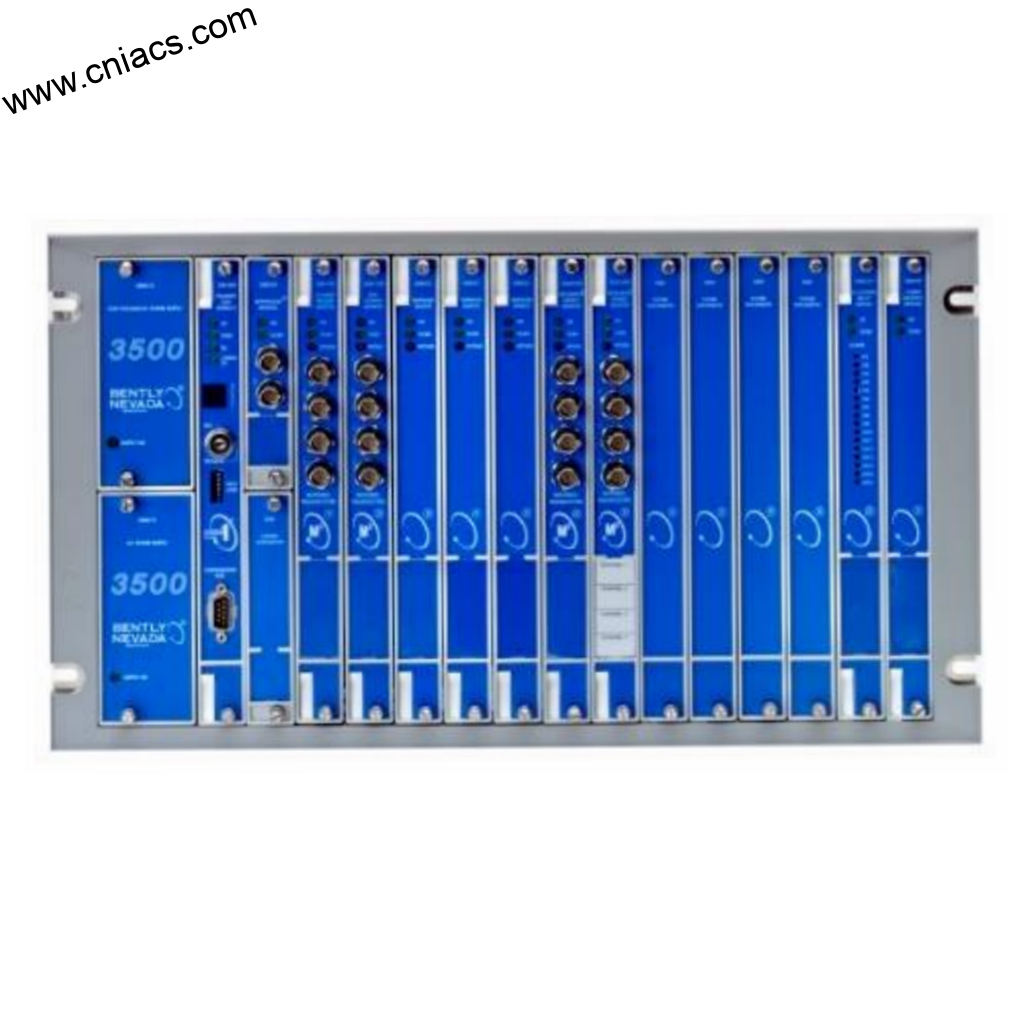

BENTLY 3500/22M 288055-01 Vibration Monitoring Module

Introducing the BENTLY 3500/22M: The Pinnacle of Vibration Monitoring

In the realm of industrial automation, the BENTLY 3500/22M stands out as a premier vibration monitoring solution, expertly engineered to enhance the reliability and performance of rotating machinery. This state-of-the-art model is a vital component in the BENTLY automation products line, designed to provide real-time insights and unparalleled protection for your assets.

Key Technical Features

The BENTLY 3500/22M is characterized by its exceptional technical features, which include:

1. **Advanced Vibration Analysis**: The 3500/22M utilizes cutting-edge algorithms for real-time vibration analysis, enabling precise monitoring of machinery health. With the ability to detect early signs of wear and fatigue, it allows for proactive maintenance strategies.

2. **Dual-Channel Input**: This model supports dual-channel input, allowing it to measure both vibration and displacement simultaneously. This capability is essential for comprehensive condition monitoring, ensuring that critical parameters are tracked effectively.

3. **Wide Frequency Range**: The BENTLY 3500/22M operates within a wide frequency range, catering to various applications. Whether it’s high-speed turbines or slow-speed fans, this model can handle the demands of diverse industrial environments.

4. **Robust Build Quality**: Designed for harsh industrial settings, the 3500/22M features a rugged chassis that withstands vibrations, temperature fluctuations, and other environmental stressors. This durability ensures longevity and consistent performance over time.

5. **User-Friendly Interface**: The intuitive interface of the BENTLY 3500/22M simplifies data interpretation and enhances user experience. Operators can easily access real-time data, historical trends, and alerts, facilitating informed decision-making.

6. **Seamless Integration**: The 3500/22M seamlessly integrates with existing BENTLY automation products, allowing for a comprehensive monitoring system. Its compatibility with other models enhances the overall functionality of your machinery health management strategy.

Usage Scenarios

The BENTLY 3500/22M is ideal for various industrial applications, including:

– **Power Generation**: In power plants, the 3500/22M can monitor steam and gas turbines, ensuring optimal performance and reducing unplanned outages through timely maintenance interventions.

– **Oil and Gas**: The model is suitable for upstream and downstream processes, where it monitors pumps, compressors, and other rotating equipment, contributing

The above parameters are for reference only. Please contact our technical team for precise selection.

In the realm of industrial automation, the BENTLY 3500/22M stands out as a premier vibration monitoring solution, expertly engineered to enhance the reliability and performance of rotating machinery. This state-of-the-art model is a vital component in the BENTLY automation products line, designed to provide real-time insights and unparalleled protection for your assets.

Key Technical Features

The BENTLY 3500/22M is characterized by its exceptional technical features, which include:

1. **Advanced Vibration Analysis**: The 3500/22M utilizes cutting-edge algorithms for real-time vibration analysis, enabling precise monitoring of machinery health. With the ability to detect early signs of wear and fatigue, it allows for proactive maintenance strategies.

2. **Dual-Channel Input**: This model supports dual-channel input, allowing it to measure both vibration and displacement simultaneously. This capability is essential for comprehensive condition monitoring, ensuring that critical parameters are tracked effectively.

3. **Wide Frequency Range**: The BENTLY 3500/22M operates within a wide frequency range, catering to various applications. Whether it’s high-speed turbines or slow-speed fans, this model can handle the demands of diverse industrial environments.

4. **Robust Build Quality**: Designed for harsh industrial settings, the 3500/22M features a rugged chassis that withstands vibrations, temperature fluctuations, and other environmental stressors. This durability ensures longevity and consistent performance over time.

5. **User-Friendly Interface**: The intuitive interface of the BENTLY 3500/22M simplifies data interpretation and enhances user experience. Operators can easily access real-time data, historical trends, and alerts, facilitating informed decision-making.

6. **Seamless Integration**: The 3500/22M seamlessly integrates with existing BENTLY automation products, allowing for a comprehensive monitoring system. Its compatibility with other models enhances the overall functionality of your machinery health management strategy.

Usage Scenarios

The BENTLY 3500/22M is ideal for various industrial applications, including:

– **Power Generation**: In power plants, the 3500/22M can monitor steam and gas turbines, ensuring optimal performance and reducing unplanned outages through timely maintenance interventions.

– **Oil and Gas**: The model is suitable for upstream and downstream processes, where it monitors pumps, compressors, and other rotating equipment, contributing

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.jpg?v=1739320885)

There are no reviews yet.