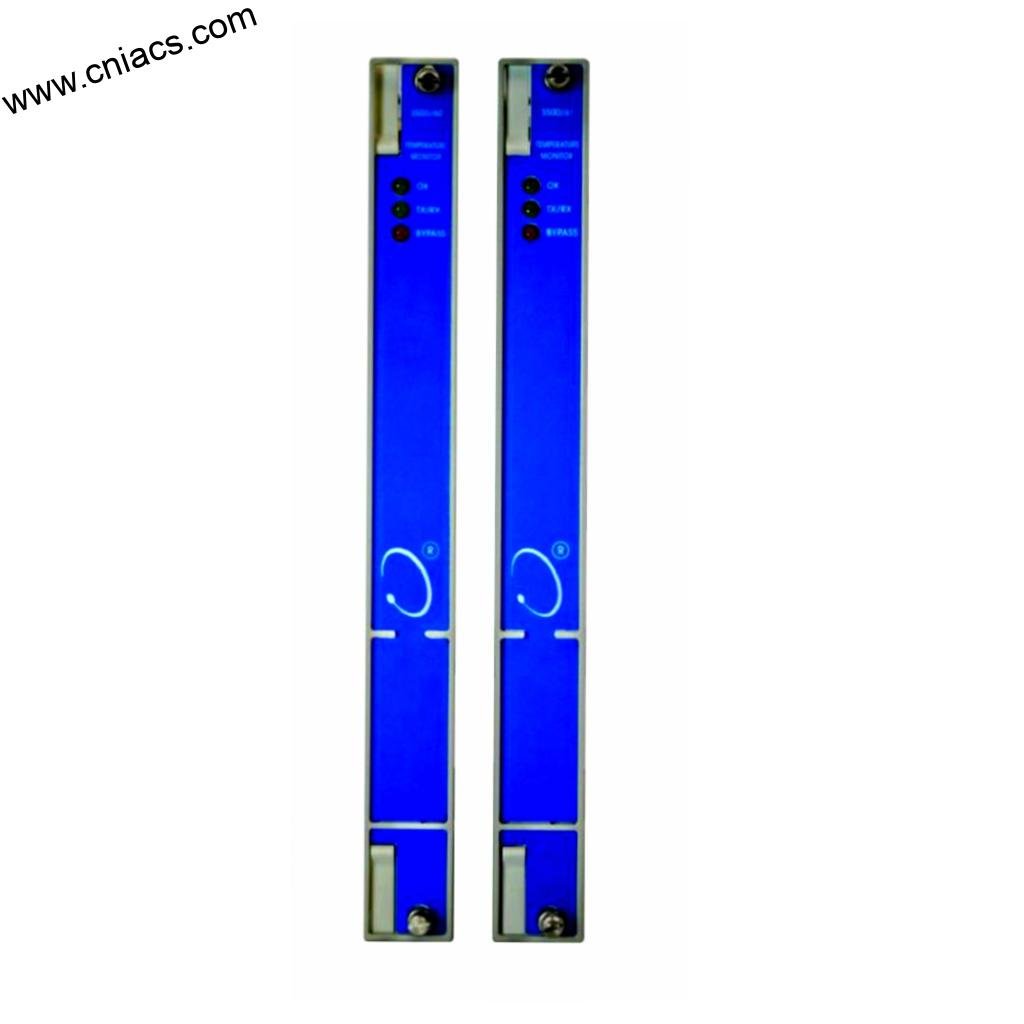

BENTLY 3500/40M 140734-01 Vibration Monitoring Module

Introducing the BENTLY 3500/40M – a pinnacle of advanced monitoring technology designed for high-performance industrial applications. As part of the renowned BENTLY automation products line, the 3500/40M model excels in vibration monitoring, providing unparalleled reliability and precision for critical machinery.

Key Technical Features

The BENTLY 3500/40M is engineered to deliver optimal performance in a compact form factor. It features state-of-the-art signal processing capabilities that allow for real-time monitoring of vibration levels, ensuring that your machinery operates within safe parameters. The model supports multiple input channels, facilitating the integration of various sensors for comprehensive monitoring solutions. With its high-resolution digitization, the 3500/40M captures minute changes in vibration, enabling predictive maintenance and reducing the risk of unplanned downtime.

One of the standout features of the BENTLY 3500/40M is its advanced diagnostics capabilities. The model employs sophisticated algorithms to analyze vibration data, providing insights into the health of rotating equipment. This proactive approach to maintenance allows for the early detection of potential issues, significantly enhancing operational efficiency. Additionally, the 3500/40M is equipped with extensive alarm settings, enabling users to customize thresholds based on specific operational requirements.

The model is designed with ruggedness in mind, featuring an industrial-grade enclosure that withstands harsh environments. Its compatibility with various BENTLY series sensors, such as the 3300 and 3500 series, further enhances its adaptability in diverse applications.

Usage Scenarios

The BENTLY 3500/40M is ideal for a myriad of industrial applications, particularly in sectors where machinery reliability is critical. It is extensively used in power generation, oil and gas extraction, and manufacturing operations. In power plants, the model monitors turbine and pump vibrations, ensuring optimal performance and preventing catastrophic failures. In oil and gas applications, it safeguards critical rotating equipment, such as compressors and turbines, from excessive wear and tear, which can lead to costly downtime.

Moreover, the 3500/40M is invaluable in manufacturing settings where precision is key. It enables manufacturers to maintain their machinery in peak condition, ensuring product quality remains consistent. The model is also suitable for use in environments with extreme temperatures, vibrations, and moisture, making it versatile for different operational needs.

Comparison with Other Models

When comparing the BENTLY 3500/40M to other models in the BENTLY automation products range, its unique features stand out. For instance

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY 3500/40M is engineered to deliver optimal performance in a compact form factor. It features state-of-the-art signal processing capabilities that allow for real-time monitoring of vibration levels, ensuring that your machinery operates within safe parameters. The model supports multiple input channels, facilitating the integration of various sensors for comprehensive monitoring solutions. With its high-resolution digitization, the 3500/40M captures minute changes in vibration, enabling predictive maintenance and reducing the risk of unplanned downtime.

One of the standout features of the BENTLY 3500/40M is its advanced diagnostics capabilities. The model employs sophisticated algorithms to analyze vibration data, providing insights into the health of rotating equipment. This proactive approach to maintenance allows for the early detection of potential issues, significantly enhancing operational efficiency. Additionally, the 3500/40M is equipped with extensive alarm settings, enabling users to customize thresholds based on specific operational requirements.

The model is designed with ruggedness in mind, featuring an industrial-grade enclosure that withstands harsh environments. Its compatibility with various BENTLY series sensors, such as the 3300 and 3500 series, further enhances its adaptability in diverse applications.

Usage Scenarios

The BENTLY 3500/40M is ideal for a myriad of industrial applications, particularly in sectors where machinery reliability is critical. It is extensively used in power generation, oil and gas extraction, and manufacturing operations. In power plants, the model monitors turbine and pump vibrations, ensuring optimal performance and preventing catastrophic failures. In oil and gas applications, it safeguards critical rotating equipment, such as compressors and turbines, from excessive wear and tear, which can lead to costly downtime.

Moreover, the 3500/40M is invaluable in manufacturing settings where precision is key. It enables manufacturers to maintain their machinery in peak condition, ensuring product quality remains consistent. The model is also suitable for use in environments with extreme temperatures, vibrations, and moisture, making it versatile for different operational needs.

Comparison with Other Models

When comparing the BENTLY 3500/40M to other models in the BENTLY automation products range, its unique features stand out. For instance

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.png?v=1739321142)

There are no reviews yet.