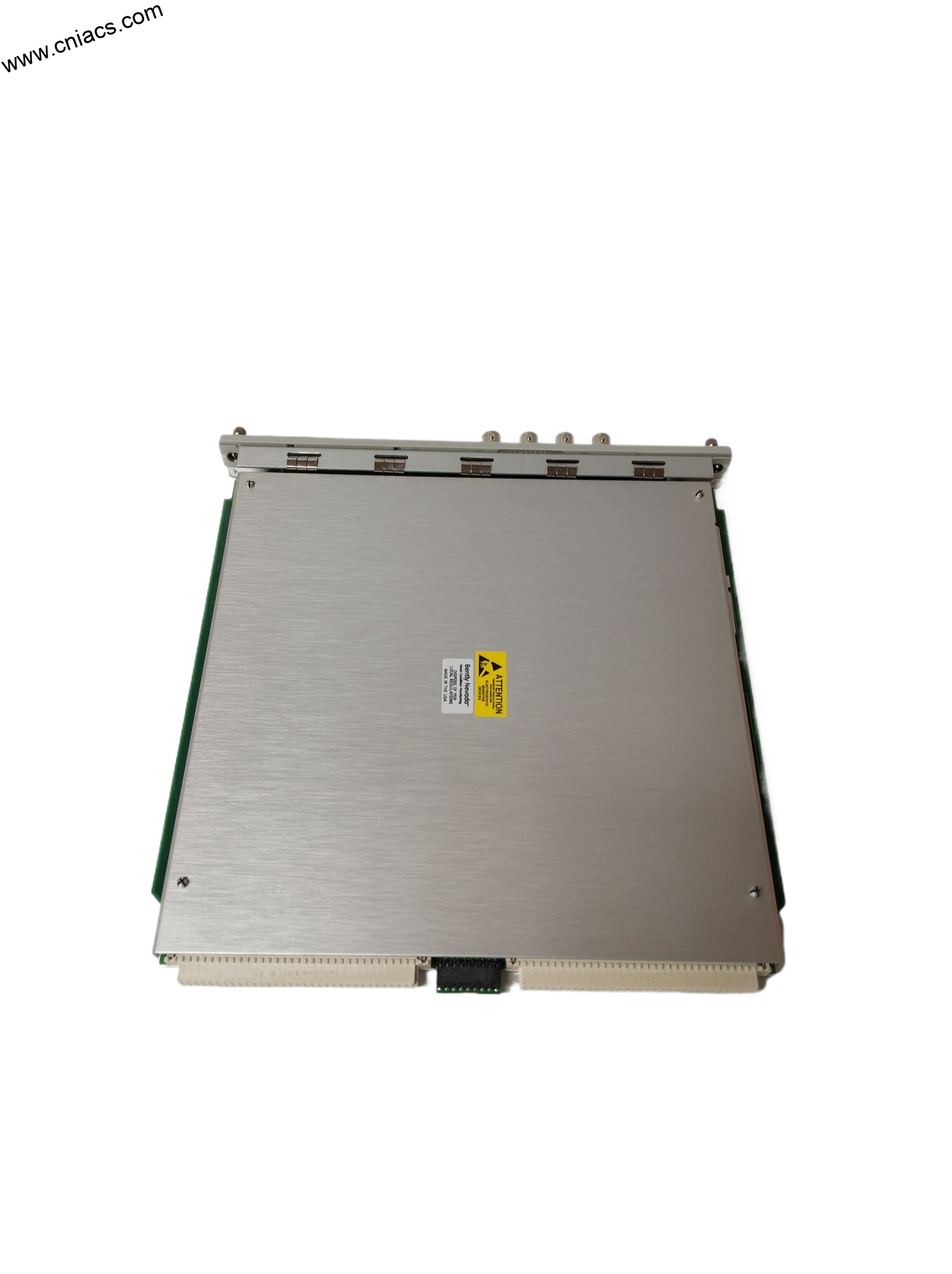

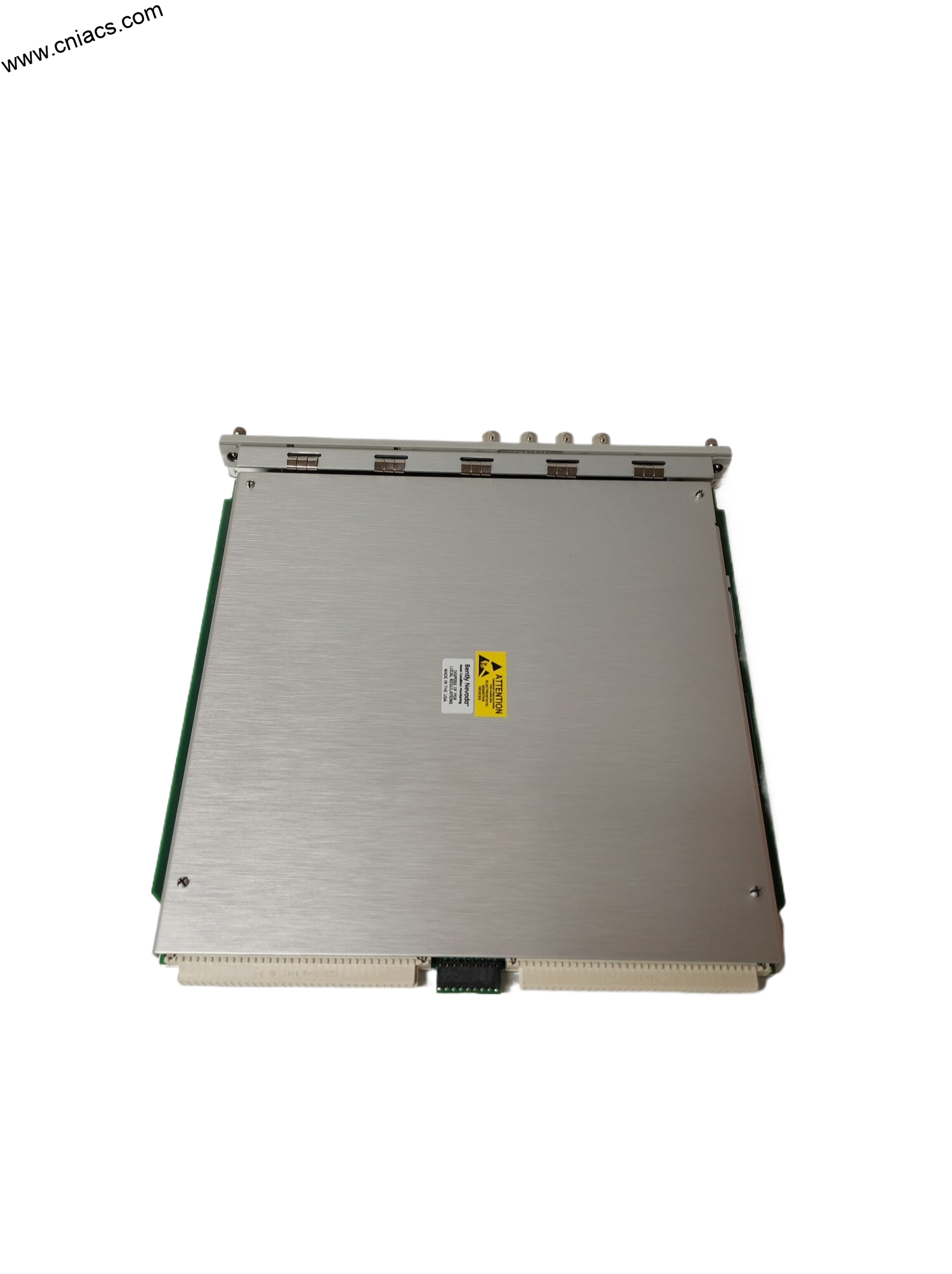

BENTLY 3500/53 133388-01 Industrial Control Module

.png)

Introducing the BENTLY 3500/53 133388-01, the pinnacle of reliability and precision in the realm of condition monitoring and automation solutions. Designed to meet the rigorous demands of industrial applications, this model is a vital component for any facility aiming to enhance its operational efficiency and safety.

Key Technical Features

The BENTLY 3500/53 133388-01 is engineered with state-of-the-art technology that ensures optimal performance and durability. At the heart of its functionality is its advanced vibration monitoring capabilities, which utilize high-resolution sensors to detect even the slightest changes in machinery performance. This enables predictive maintenance, allowing operators to address potential issues before they escalate into costly failures.

One of the standout features of the BENTLY 3500/53 is its compatibility with a wide range of sensors and transducers. This versatility allows for seamless integration into existing systems, facilitating easy upgrades or replacements without the need for extensive modifications. The model also boasts a user-friendly interface, making it accessible for operators of all skill levels.

In addition, the BENTLY 3500/53 133388-01 supports real-time data acquisition and analysis, providing critical insights into the health of your equipment. Its robust communication protocols ensure that data can be easily transmitted to central control systems, enhancing monitoring efficiency. The model is designed to operate in harsh industrial environments, with a rugged construction that withstands extreme temperatures, vibrations, and electrical interference.

Usage Scenarios

The BENTLY 3500/53 133388-01 is ideal for a variety of industries, including oil and gas, power generation, manufacturing, and water treatment. In oil and gas, for instance, it can be deployed to monitor rotating equipment such as pumps and compressors, ensuring they operate within safe parameters. This not only minimizes downtime but also extends the lifespan of critical machinery.

In power generation, the BENTLY 3500/53 plays a key role in turbine and generator monitoring, where precision is paramount. By detecting anomalies in vibration patterns, operators can prevent catastrophic failures that could lead to costly outages. Similarly, in manufacturing environments, this model can be utilized to oversee conveyor systems, motors, and other key equipment, ensuring streamlined operations.

Comparison with Other Models

When compared to other models in the BENTLY line, such as the BENTLY 3500/20 125744-02 and the BENTLY 3500/40M, the 3500/53 stands out

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY 3500/53 133388-01 is engineered with state-of-the-art technology that ensures optimal performance and durability. At the heart of its functionality is its advanced vibration monitoring capabilities, which utilize high-resolution sensors to detect even the slightest changes in machinery performance. This enables predictive maintenance, allowing operators to address potential issues before they escalate into costly failures.

One of the standout features of the BENTLY 3500/53 is its compatibility with a wide range of sensors and transducers. This versatility allows for seamless integration into existing systems, facilitating easy upgrades or replacements without the need for extensive modifications. The model also boasts a user-friendly interface, making it accessible for operators of all skill levels.

In addition, the BENTLY 3500/53 133388-01 supports real-time data acquisition and analysis, providing critical insights into the health of your equipment. Its robust communication protocols ensure that data can be easily transmitted to central control systems, enhancing monitoring efficiency. The model is designed to operate in harsh industrial environments, with a rugged construction that withstands extreme temperatures, vibrations, and electrical interference.

Usage Scenarios

The BENTLY 3500/53 133388-01 is ideal for a variety of industries, including oil and gas, power generation, manufacturing, and water treatment. In oil and gas, for instance, it can be deployed to monitor rotating equipment such as pumps and compressors, ensuring they operate within safe parameters. This not only minimizes downtime but also extends the lifespan of critical machinery.

In power generation, the BENTLY 3500/53 plays a key role in turbine and generator monitoring, where precision is paramount. By detecting anomalies in vibration patterns, operators can prevent catastrophic failures that could lead to costly outages. Similarly, in manufacturing environments, this model can be utilized to oversee conveyor systems, motors, and other key equipment, ensuring streamlined operations.

Comparison with Other Models

When compared to other models in the BENTLY line, such as the BENTLY 3500/20 125744-02 and the BENTLY 3500/40M, the 3500/53 stands out

The above parameters are for reference only. Please contact our technical team for precise selection.

.png?v=1739321133)

There are no reviews yet.