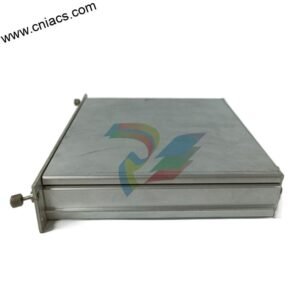

BENTLY Nevada 125808-02A Terminal Block Board, Industrial Control Module

Introducing the BENTLY Nevada: The Pinnacle of Condition Monitoring and Automation Technology

The BENTLY Nevada model stands at the forefront of industrial condition monitoring solutions, embodying the innovation and reliability that BENTLY is renowned for. Designed for a wide range of applications, the BENTLY Nevada series delivers unparalleled performance, ensuring your machinery operates at peak efficiency. This comprehensive product description delves into its key technical features, usage scenarios, comparisons with other models, and references related models to help you understand why the BENTLY Nevada is the ideal choice for your automation needs.

Key Technical Features

The BENTLY Nevada is equipped with advanced technology that makes it a leader in condition monitoring. Some of its key technical features include:

1. **High-Performance Sensors**: The BENTLY Nevada employs precision sensors capable of capturing real-time vibration, displacement, and temperature data. These sensors provide accurate insights into equipment health, allowing for timely interventions.

2. **Robust Data Acquisition**: With a high-speed data acquisition system, the BENTLY Nevada can collect and analyze large volumes of data swiftly. This feature is critical for industries where rapid decision-making is essential.

3. **User-Friendly Interface**: The interface is designed for ease of use. Operators can navigate through the system effortlessly, allowing for quick adjustments and real-time monitoring without extensive training.

4. **Versatile Communication Protocols**: Supporting multiple communication protocols, the BENTLY Nevada seamlessly integrates with existing systems, enhancing interoperability with other BENTLY automation products and third-party devices.

5. **Scalability**: The system’s modular design allows for easy expansion as your monitoring needs grow. Whether you’re monitoring a single machine or an entire plant, the BENTLY Nevada can be tailored to fit your requirements.

6. **Advanced Analytics**: The built-in analytics tools provide actionable insights, helping to predict equipment failures and optimize maintenance schedules. This predictive capability significantly reduces downtime and maintenance costs.

Usage Scenarios

The BENTLY Nevada is exceptionally versatile and can be utilized across various industries. Here are some common usage scenarios:

1. **Oil and Gas**: In the oil and gas sector, the BENTLY Nevada is instrumental in monitoring pumps, compressors, and turbines. Its reliable data helps prevent catastrophic failures, ensuring continuous operation in critical environments.

2. **Power Generation**: This model is widely used in power plants for monitoring rotating machinery. Its ability to detect anomalies early on facilitates proactive maintenance

The above parameters are for reference only. Please contact our technical team for precise selection.

The BENTLY Nevada model stands at the forefront of industrial condition monitoring solutions, embodying the innovation and reliability that BENTLY is renowned for. Designed for a wide range of applications, the BENTLY Nevada series delivers unparalleled performance, ensuring your machinery operates at peak efficiency. This comprehensive product description delves into its key technical features, usage scenarios, comparisons with other models, and references related models to help you understand why the BENTLY Nevada is the ideal choice for your automation needs.

Key Technical Features

The BENTLY Nevada is equipped with advanced technology that makes it a leader in condition monitoring. Some of its key technical features include:

1. **High-Performance Sensors**: The BENTLY Nevada employs precision sensors capable of capturing real-time vibration, displacement, and temperature data. These sensors provide accurate insights into equipment health, allowing for timely interventions.

2. **Robust Data Acquisition**: With a high-speed data acquisition system, the BENTLY Nevada can collect and analyze large volumes of data swiftly. This feature is critical for industries where rapid decision-making is essential.

3. **User-Friendly Interface**: The interface is designed for ease of use. Operators can navigate through the system effortlessly, allowing for quick adjustments and real-time monitoring without extensive training.

4. **Versatile Communication Protocols**: Supporting multiple communication protocols, the BENTLY Nevada seamlessly integrates with existing systems, enhancing interoperability with other BENTLY automation products and third-party devices.

5. **Scalability**: The system’s modular design allows for easy expansion as your monitoring needs grow. Whether you’re monitoring a single machine or an entire plant, the BENTLY Nevada can be tailored to fit your requirements.

6. **Advanced Analytics**: The built-in analytics tools provide actionable insights, helping to predict equipment failures and optimize maintenance schedules. This predictive capability significantly reduces downtime and maintenance costs.

Usage Scenarios

The BENTLY Nevada is exceptionally versatile and can be utilized across various industries. Here are some common usage scenarios:

1. **Oil and Gas**: In the oil and gas sector, the BENTLY Nevada is instrumental in monitoring pumps, compressors, and turbines. Its reliable data helps prevent catastrophic failures, ensuring continuous operation in critical environments.

2. **Power Generation**: This model is widely used in power plants for monitoring rotating machinery. Its ability to detect anomalies early on facilitates proactive maintenance

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.jpg?v=1739237723)

There are no reviews yet.