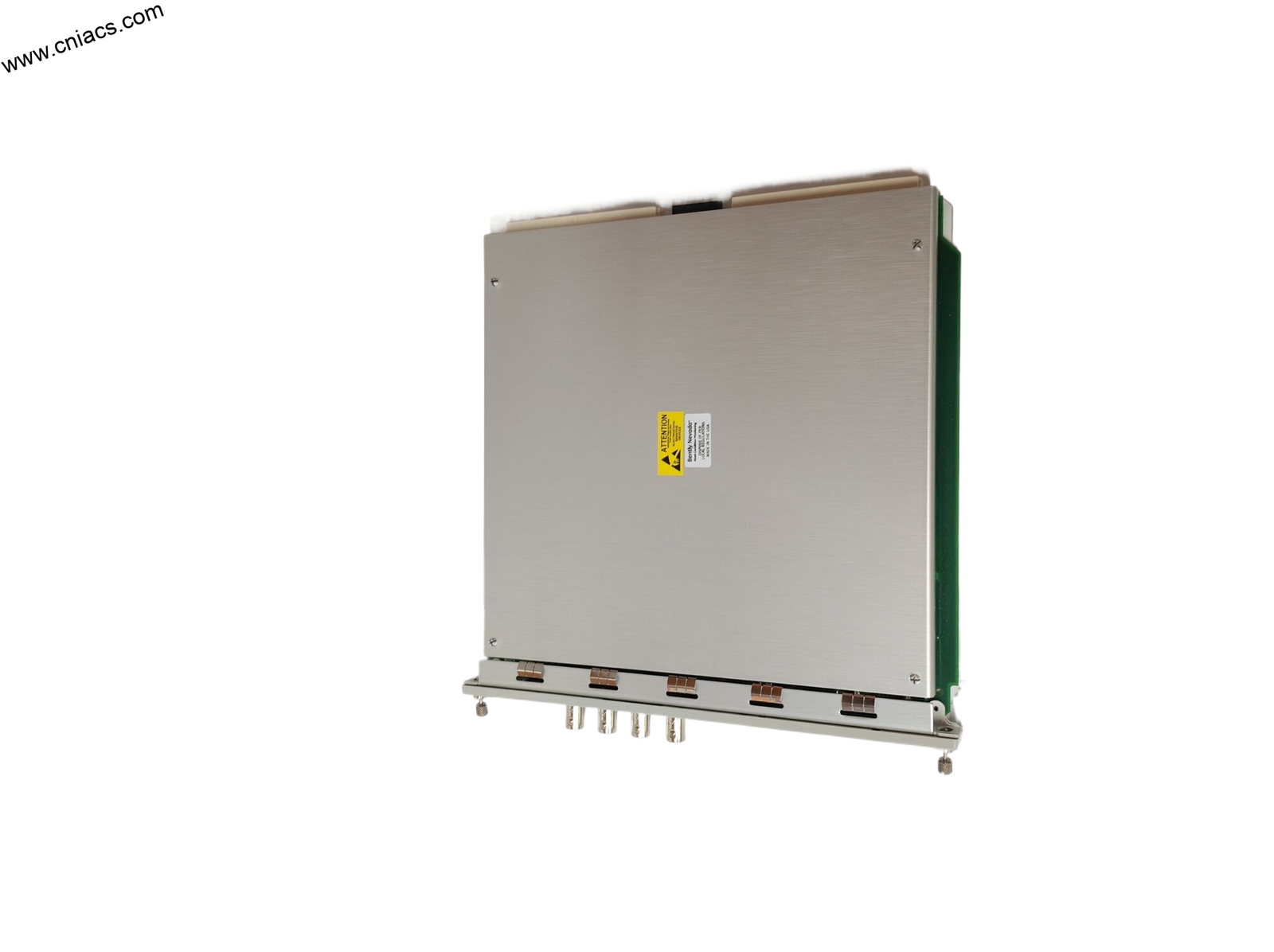

BENTLY Nevada 136711-01 Industrial Control Module Extension Cable, Optimized for Precision Automation

Introducing the BENTLY Nevada 136711-01: an advanced solution in the realm of machinery monitoring and automation. As part of the renowned BENTLY automation products family, this model stands out with its innovative features and exceptional performance, tailored to meet the rigorous demands of various industrial applications.

Key Technical Features

The BENTLY Nevada 136711-01 is engineered for precision and reliability. This model integrates advanced sensing technology, which allows for real-time monitoring of machinery vibrations, temperature, and other critical parameters. Equipped with high-quality sensors, it ensures accurate data collection, enabling predictive maintenance and reducing unexpected downtimes.

Key technical features include:

1. **Real-time Data Monitoring**: The BENTLY Nevada 136711-01 provides continuous data capture, allowing operators to monitor machine health in real-time. This feature is crucial for early detection of potential issues.

2. **Robust Design**: Built to withstand harsh environments, the BENTLY Nevada 136711-01 boasts a durable casing that protects internal components from dust, moisture, and temperature fluctuations.

3. **Compatibility**: This model seamlessly integrates with existing BENTLY systems, including the BENTLY 3500 series and other automation products. This ensures a cohesive operational framework for enhanced monitoring capabilities.

4. **User-Friendly Interface**: The intuitive interface simplifies operation and data interpretation, making it accessible for technicians and engineers alike.

5. **Scalability**: The system can be expanded to accommodate additional sensors and components, making it suitable for both small and large-scale applications.

Usage Scenarios

The BENTLY Nevada 136711-01 is designed for a wide array of industrial applications where machinery reliability is paramount. Here are some common usage scenarios:

1. **Power Generation**: In power plants, the 136711-01 monitors turbines and generators, ensuring they operate within safe parameters and preventing costly outages.

2. **Oil and Gas**: The model is ideal for upstream and downstream operations, providing critical data on pumps and compressors to enhance operational efficiency.

3. **Manufacturing**: In manufacturing settings, the BENTLY Nevada 136711-01 helps maintain equipment such as conveyors and motors, improving production uptime.

4. **Mining**: It is used to monitor heavy equipment in mining operations, where machinery reliability is essential for productivity and safety.

5. **Marine Applications**: The model can be employed in marine engines and propulsion systems, ensuring optimal performance and minimizing

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY Nevada 136711-01 is engineered for precision and reliability. This model integrates advanced sensing technology, which allows for real-time monitoring of machinery vibrations, temperature, and other critical parameters. Equipped with high-quality sensors, it ensures accurate data collection, enabling predictive maintenance and reducing unexpected downtimes.

Key technical features include:

1. **Real-time Data Monitoring**: The BENTLY Nevada 136711-01 provides continuous data capture, allowing operators to monitor machine health in real-time. This feature is crucial for early detection of potential issues.

2. **Robust Design**: Built to withstand harsh environments, the BENTLY Nevada 136711-01 boasts a durable casing that protects internal components from dust, moisture, and temperature fluctuations.

3. **Compatibility**: This model seamlessly integrates with existing BENTLY systems, including the BENTLY 3500 series and other automation products. This ensures a cohesive operational framework for enhanced monitoring capabilities.

4. **User-Friendly Interface**: The intuitive interface simplifies operation and data interpretation, making it accessible for technicians and engineers alike.

5. **Scalability**: The system can be expanded to accommodate additional sensors and components, making it suitable for both small and large-scale applications.

Usage Scenarios

The BENTLY Nevada 136711-01 is designed for a wide array of industrial applications where machinery reliability is paramount. Here are some common usage scenarios:

1. **Power Generation**: In power plants, the 136711-01 monitors turbines and generators, ensuring they operate within safe parameters and preventing costly outages.

2. **Oil and Gas**: The model is ideal for upstream and downstream operations, providing critical data on pumps and compressors to enhance operational efficiency.

3. **Manufacturing**: In manufacturing settings, the BENTLY Nevada 136711-01 helps maintain equipment such as conveyors and motors, improving production uptime.

4. **Mining**: It is used to monitor heavy equipment in mining operations, where machinery reliability is essential for productivity and safety.

5. **Marine Applications**: The model can be employed in marine engines and propulsion systems, ensuring optimal performance and minimizing

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.png?v=1739321142)

There are no reviews yet.