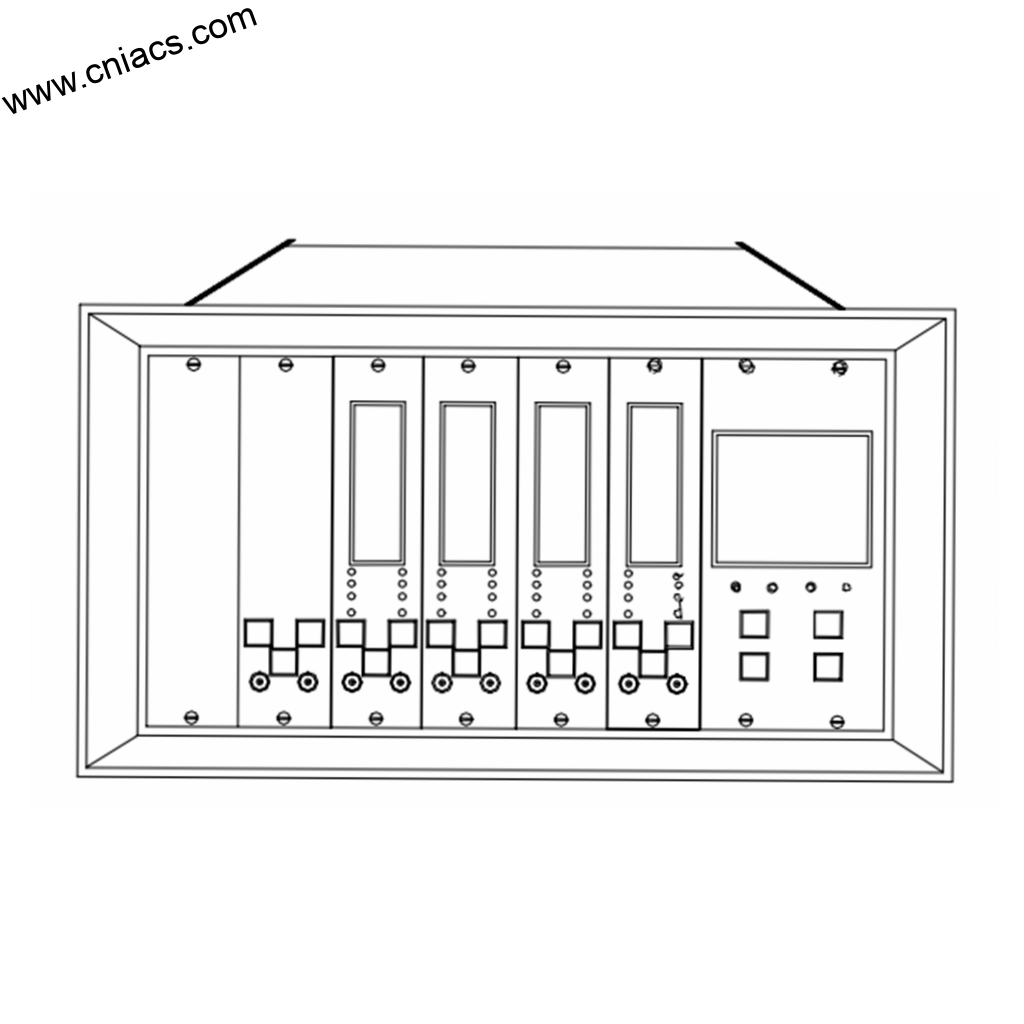

BENTLY Nevada 1900/65A, 172323-01 General Purpose Equipment Monitor

Introducing the BENTLY Nevada 1900/65A, 172323-01 – a cutting-edge solution in the realm of industrial automation and condition monitoring. Renowned for its precision and reliability, the BENTLY Nevada 1900/65A is designed to provide comprehensive monitoring capabilities for critical machinery, ensuring optimal performance and longevity.

Key Technical Features

The BENTLY Nevada 1900/65A, 172323-01 stands out with its robust set of features tailored for industrial applications. At the core of its functionality is its advanced vibration monitoring technology, enabling the detection of even the slightest deviations from normal operating conditions. This model is equipped with high-resolution sensors that provide real-time data on vibration, temperature, and other critical parameters essential for diagnosing machine health.

With its user-friendly interface and intuitive software, the BENTLY Nevada 1900/65A simplifies data interpretation and enables users to make informed decisions about maintenance schedules. The device supports various communication protocols, ensuring seamless integration with existing BENTLY automation products and other industrial control systems. Furthermore, the model boasts exceptional durability, designed to withstand the harsh environments typically found in manufacturing and processing facilities.

Usage Scenarios

The versatility of the BENTLY Nevada 1900/65A, 172323-01 makes it ideal for a wide range of applications across various industries. In power generation plants, it is instrumental in monitoring turbines and generators, providing critical insights that can prevent costly downtime. Similarly, in oil and gas refineries, the device monitors pumps, compressors, and other rotating equipment, enabling operators to maintain peak performance and avoid catastrophic failures.

In the manufacturing sector, the BENTLY Nevada 1900/65A is employed for monitoring conveyor systems and other machinery, enhancing operational efficiency and reducing maintenance costs. Its ability to provide predictive maintenance insights empowers facilities to transition from reactive to proactive maintenance strategies, ultimately leading to improved productivity and reduced operational risks.

Comparison with Other Models

When comparing the BENTLY Nevada 1900/65A, 172323-01 to other models within the BENTLY lineup, it becomes evident that its unique features position it as a premier choice for many applications. For instance, the BENTLY 3500/20 125744-02 and BENTLY 3500/40M models offer solid performance, but the 1900/65A excels in its real-time data capabilities and advanced diagnostics.

While models like the BENTLY

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY Nevada 1900/65A, 172323-01 stands out with its robust set of features tailored for industrial applications. At the core of its functionality is its advanced vibration monitoring technology, enabling the detection of even the slightest deviations from normal operating conditions. This model is equipped with high-resolution sensors that provide real-time data on vibration, temperature, and other critical parameters essential for diagnosing machine health.

With its user-friendly interface and intuitive software, the BENTLY Nevada 1900/65A simplifies data interpretation and enables users to make informed decisions about maintenance schedules. The device supports various communication protocols, ensuring seamless integration with existing BENTLY automation products and other industrial control systems. Furthermore, the model boasts exceptional durability, designed to withstand the harsh environments typically found in manufacturing and processing facilities.

Usage Scenarios

The versatility of the BENTLY Nevada 1900/65A, 172323-01 makes it ideal for a wide range of applications across various industries. In power generation plants, it is instrumental in monitoring turbines and generators, providing critical insights that can prevent costly downtime. Similarly, in oil and gas refineries, the device monitors pumps, compressors, and other rotating equipment, enabling operators to maintain peak performance and avoid catastrophic failures.

In the manufacturing sector, the BENTLY Nevada 1900/65A is employed for monitoring conveyor systems and other machinery, enhancing operational efficiency and reducing maintenance costs. Its ability to provide predictive maintenance insights empowers facilities to transition from reactive to proactive maintenance strategies, ultimately leading to improved productivity and reduced operational risks.

Comparison with Other Models

When comparing the BENTLY Nevada 1900/65A, 172323-01 to other models within the BENTLY lineup, it becomes evident that its unique features position it as a premier choice for many applications. For instance, the BENTLY 3500/20 125744-02 and BENTLY 3500/40M models offer solid performance, but the 1900/65A excels in its real-time data capabilities and advanced diagnostics.

While models like the BENTLY

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.png?v=1739321142)

There are no reviews yet.