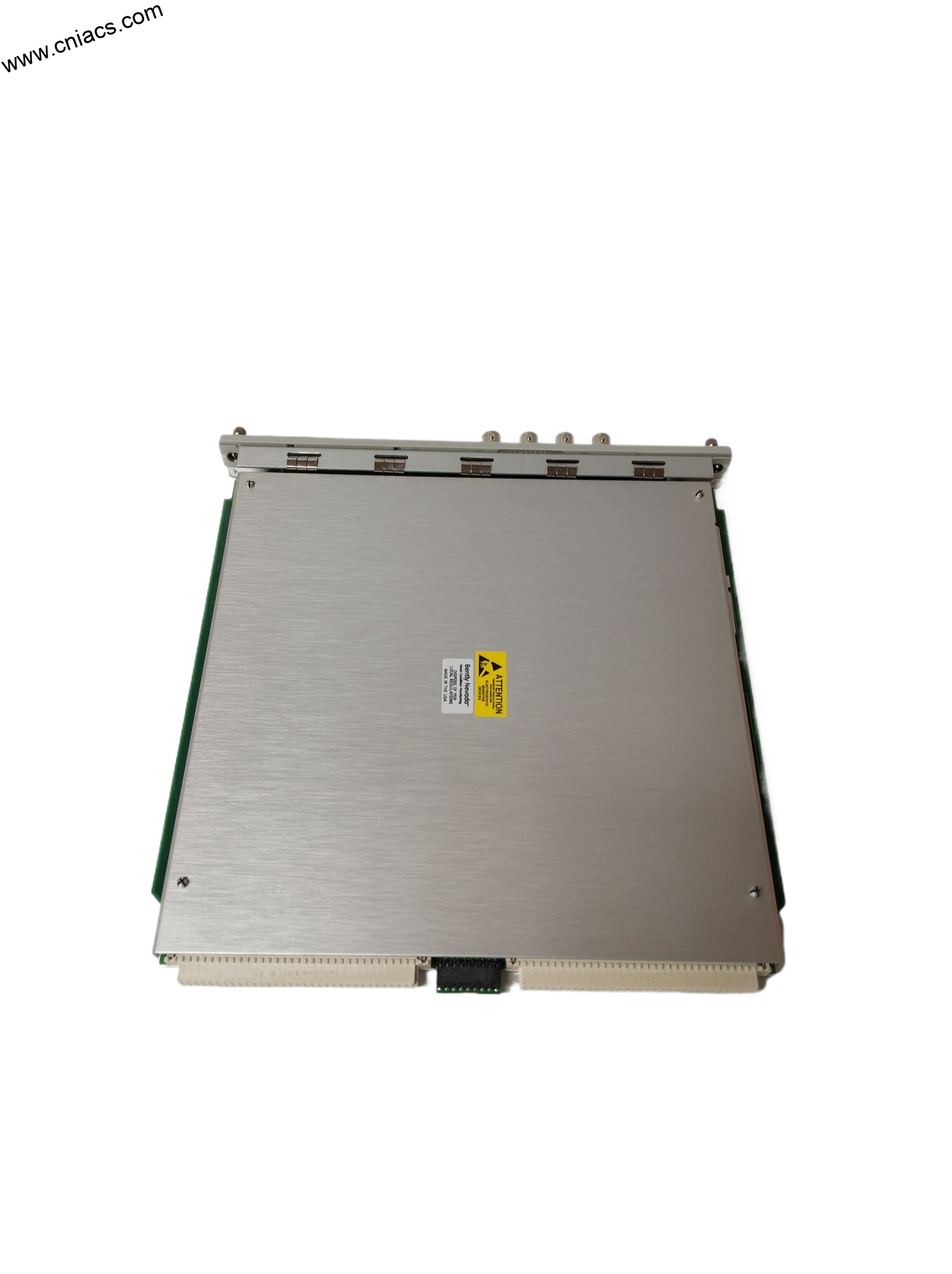

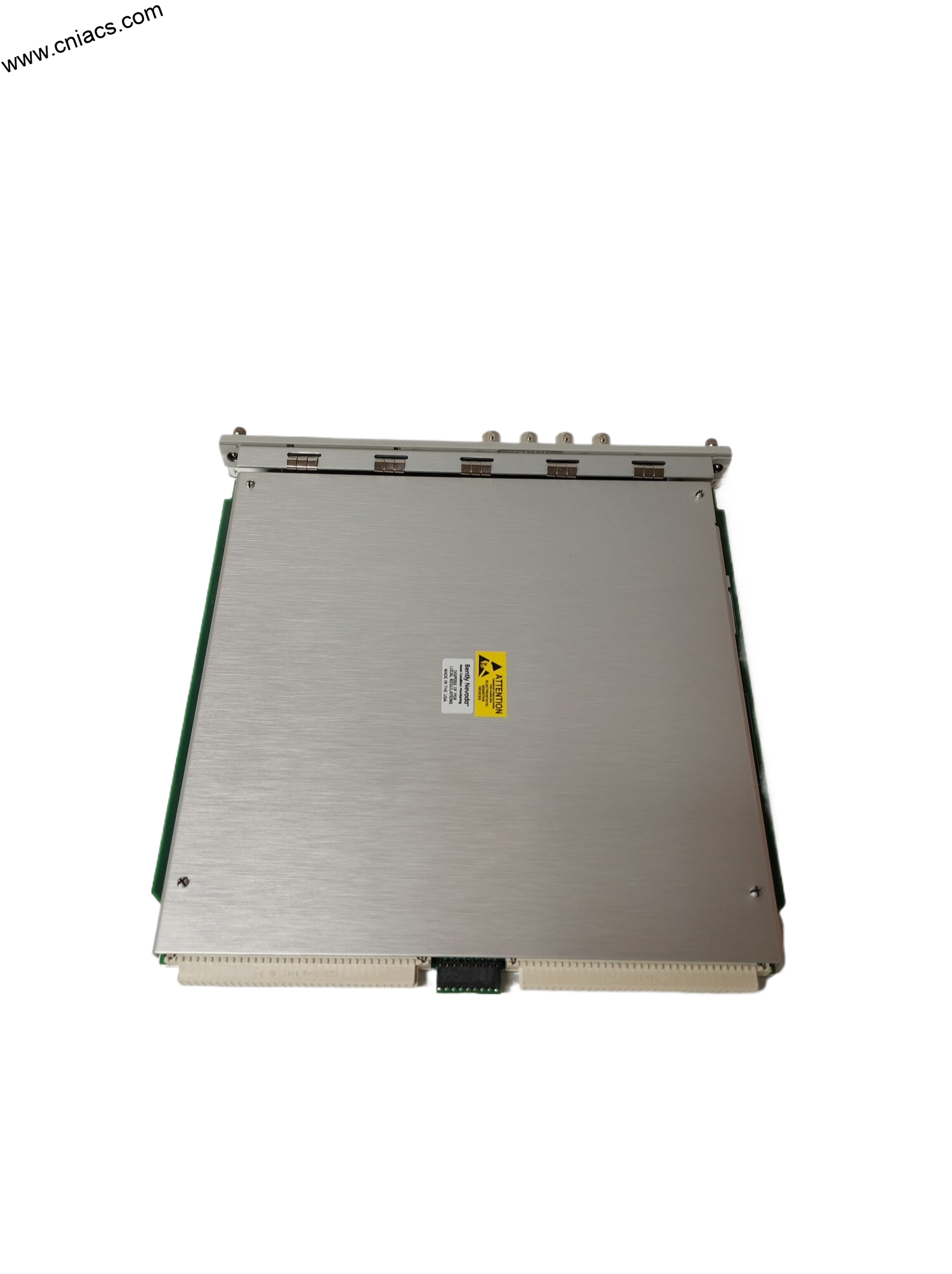

BENTLY Nevada 330101-36-80-10-02-00 Proximity Probes

Introducing the BENTLY Nevada: The Pinnacle of Condition Monitoring Solutions

BENTLY has established itself as a leader in the field of condition monitoring and machine health assessment, and the BENTLY Nevada model exemplifies this commitment to excellence. Designed for demanding industrial environments, the BENTLY Nevada integrates advanced technology with user-friendly functionality to deliver unparalleled performance in monitoring and managing rotating machinery.

Key Technical Features

The BENTLY Nevada is equipped with state-of-the-art features that enhance its reliability and efficiency. Key technical specifications include:

1. Advanced Vibration Monitoring: The BENTLY Nevada utilizes high-sensitivity sensors to accurately measure vibration levels and detect anomalies in real-time. This capability allows for early diagnosis of potential faults, minimizing downtime and maintenance costs.

2. Comprehensive Data Logging: With the ability to log and store vast amounts of data, the BENTLY Nevada enables users to analyze trends over time. This feature is crucial for predictive maintenance strategies, allowing operators to make informed decisions based on historical performance data.

3. User-Friendly Interface: The intuitive interface of the BENTLY Nevada simplifies navigation and data interpretation, making it accessible for both seasoned professionals and newcomers to the field of condition monitoring.

4. Scalability: The modular design of the BENTLY Nevada allows for easy integration with existing systems and the flexibility to expand as operational needs evolve. This adaptability ensures that businesses can grow without the constraints of outdated technology.

5. Multi-Channel Capabilities: The BENTLY Nevada supports multiple channels, allowing for simultaneous monitoring of various machines. This multi-channel functionality is essential for operations with complex machinery setups and diverse monitoring needs.

6. Robust Construction: Built to withstand harsh environments, the BENTLY Nevada features durable materials that resist corrosion, dust, and moisture. This ensures long-lasting performance in demanding industrial settings.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for a wide range of applications across various industries. Here are some typical usage scenarios:

1. Power Generation: In power plants, the BENTLY Nevada is used to monitor the health of turbines, generators, and transformers, ensuring efficient operations and preventing unexpected failures that could lead to costly outages.

2. Oil and Gas: In the oil and gas sector, the BENTLY Nevada monitors critical equipment such as pumps, compressors, and drilling rigs, helping to ensure safe and efficient extraction processes.

3. Manufacturing: Manufacturing facilities utilize the BENTLY Nevada to monitor machinery such as motors,

The above parameters are for reference only. Please contact our technical team for precise selection.

BENTLY has established itself as a leader in the field of condition monitoring and machine health assessment, and the BENTLY Nevada model exemplifies this commitment to excellence. Designed for demanding industrial environments, the BENTLY Nevada integrates advanced technology with user-friendly functionality to deliver unparalleled performance in monitoring and managing rotating machinery.

Key Technical Features

The BENTLY Nevada is equipped with state-of-the-art features that enhance its reliability and efficiency. Key technical specifications include:

1. Advanced Vibration Monitoring: The BENTLY Nevada utilizes high-sensitivity sensors to accurately measure vibration levels and detect anomalies in real-time. This capability allows for early diagnosis of potential faults, minimizing downtime and maintenance costs.

2. Comprehensive Data Logging: With the ability to log and store vast amounts of data, the BENTLY Nevada enables users to analyze trends over time. This feature is crucial for predictive maintenance strategies, allowing operators to make informed decisions based on historical performance data.

3. User-Friendly Interface: The intuitive interface of the BENTLY Nevada simplifies navigation and data interpretation, making it accessible for both seasoned professionals and newcomers to the field of condition monitoring.

4. Scalability: The modular design of the BENTLY Nevada allows for easy integration with existing systems and the flexibility to expand as operational needs evolve. This adaptability ensures that businesses can grow without the constraints of outdated technology.

5. Multi-Channel Capabilities: The BENTLY Nevada supports multiple channels, allowing for simultaneous monitoring of various machines. This multi-channel functionality is essential for operations with complex machinery setups and diverse monitoring needs.

6. Robust Construction: Built to withstand harsh environments, the BENTLY Nevada features durable materials that resist corrosion, dust, and moisture. This ensures long-lasting performance in demanding industrial settings.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for a wide range of applications across various industries. Here are some typical usage scenarios:

1. Power Generation: In power plants, the BENTLY Nevada is used to monitor the health of turbines, generators, and transformers, ensuring efficient operations and preventing unexpected failures that could lead to costly outages.

2. Oil and Gas: In the oil and gas sector, the BENTLY Nevada monitors critical equipment such as pumps, compressors, and drilling rigs, helping to ensure safe and efficient extraction processes.

3. Manufacturing: Manufacturing facilities utilize the BENTLY Nevada to monitor machinery such as motors,

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.png?v=1739321142)

There are no reviews yet.