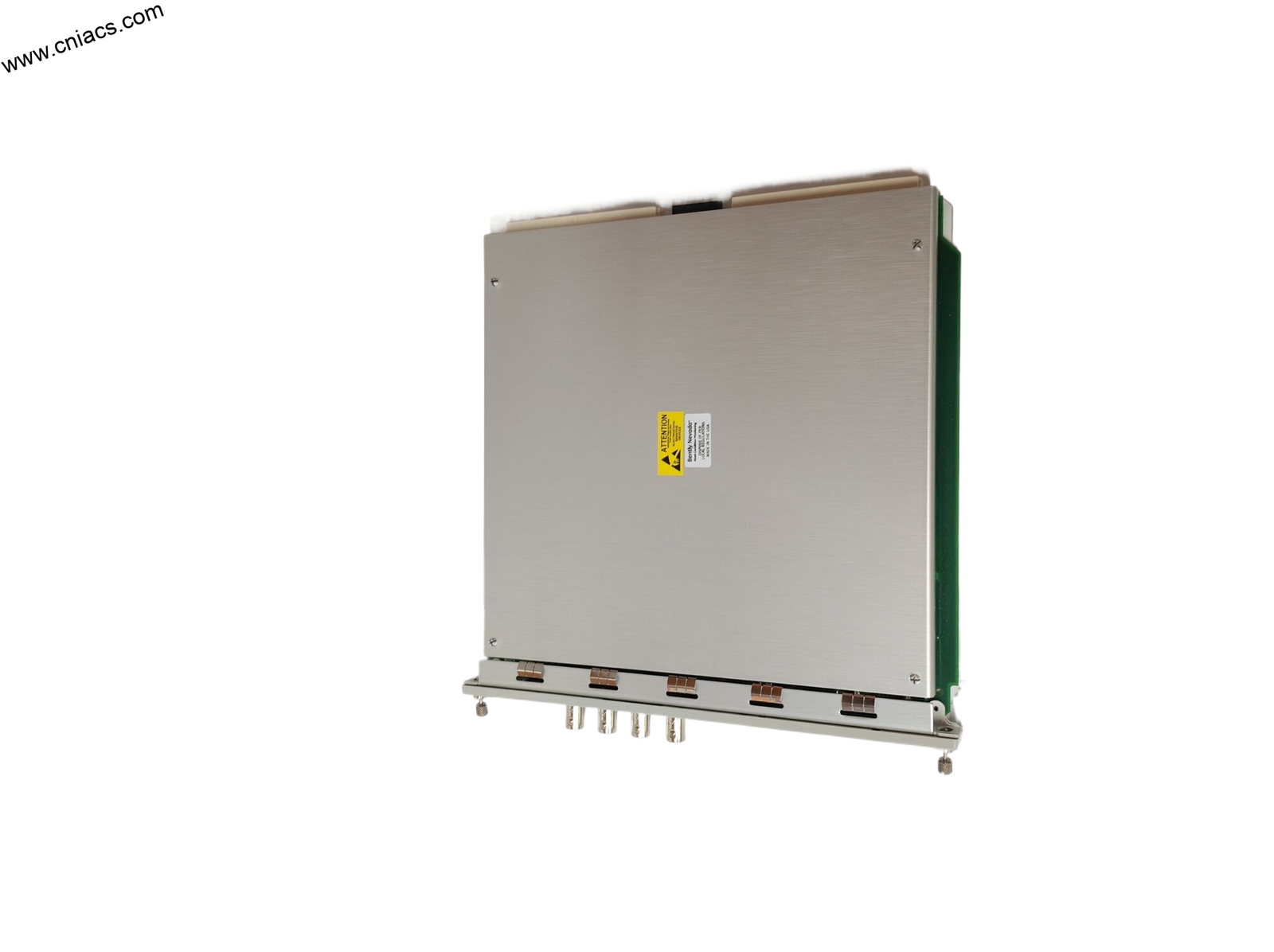

BENTLY Nevada 330102-00-16-10-02-00 Advanced 3300 XL Proximity Probe, 8 mm

Introducing the BENTLY Nevada 330102-00-16-10-02-00, a premium solution in the realm of monitoring and diagnostic tools designed for industrial applications. Engineered to enhance operational efficiency and reliability, this model stands out among BENTLY's extensive lineup of automation products, catering to industries such as oil and gas, power generation, and manufacturing.

**Key Technical Features**

The BENTLY Nevada 330102-00-16-10-02-00 boasts an array of advanced technical features that make it a vital component for any modern industrial setup. Key highlights include:

– **Precision Measurement**: This model offers high-accuracy vibration measurement, ensuring that your machinery operates within optimal parameters. It can detect minute changes in vibration patterns, allowing for early identification of potential mechanical issues.

– **Robust Connectivity**: Equipped with various communication interfaces, the BENTLY 330102-00-16-10-02-00 integrates seamlessly with existing systems. It supports both analog and digital outputs, making it versatile enough for diverse applications.

– **Durability**: Designed for harsh industrial environments, the unit features a rugged construction that withstands extreme temperatures, humidity, and vibration. This durability ensures long-term operation without the need for frequent maintenance.

– **Real-Time Monitoring**: With the ability to provide real-time data, the BENTLY Nevada 330102-00-16-10-02-00 allows operators to make informed decisions quickly, enhancing the overall safety and efficiency of operations.

– **User-Friendly Interface**: The device is designed with an intuitive interface that simplifies setup and operation, allowing personnel to access critical information with ease.

**Usage Scenarios**

The BENTLY Nevada 330102-00-16-10-02-00 is ideal for a variety of industrial applications. Common usage scenarios include:

– **Rotating Equipment Monitoring**: Used extensively in monitoring pumps, compressors, and turbines, the model helps prevent unexpected downtime by providing early warning signals for equipment failures.

– **Condition-Based Maintenance**: By integrating this model into your maintenance strategy, you can shift from traditional time-based maintenance to condition-based maintenance, optimizing resource allocation and reducing costs.

– **Data Analysis and Reporting**: This model allows for comprehensive data collection and analysis, enabling operators to generate detailed reports that can inform future maintenance schedules and operational adjustments.

– **Integration with Distributed Control Systems (DCS)**: The BENTLY Nevada 330102

The above parameters are for reference only. Please contact our technical team for precise selection.

**Key Technical Features**

The BENTLY Nevada 330102-00-16-10-02-00 boasts an array of advanced technical features that make it a vital component for any modern industrial setup. Key highlights include:

– **Precision Measurement**: This model offers high-accuracy vibration measurement, ensuring that your machinery operates within optimal parameters. It can detect minute changes in vibration patterns, allowing for early identification of potential mechanical issues.

– **Robust Connectivity**: Equipped with various communication interfaces, the BENTLY 330102-00-16-10-02-00 integrates seamlessly with existing systems. It supports both analog and digital outputs, making it versatile enough for diverse applications.

– **Durability**: Designed for harsh industrial environments, the unit features a rugged construction that withstands extreme temperatures, humidity, and vibration. This durability ensures long-term operation without the need for frequent maintenance.

– **Real-Time Monitoring**: With the ability to provide real-time data, the BENTLY Nevada 330102-00-16-10-02-00 allows operators to make informed decisions quickly, enhancing the overall safety and efficiency of operations.

– **User-Friendly Interface**: The device is designed with an intuitive interface that simplifies setup and operation, allowing personnel to access critical information with ease.

**Usage Scenarios**

The BENTLY Nevada 330102-00-16-10-02-00 is ideal for a variety of industrial applications. Common usage scenarios include:

– **Rotating Equipment Monitoring**: Used extensively in monitoring pumps, compressors, and turbines, the model helps prevent unexpected downtime by providing early warning signals for equipment failures.

– **Condition-Based Maintenance**: By integrating this model into your maintenance strategy, you can shift from traditional time-based maintenance to condition-based maintenance, optimizing resource allocation and reducing costs.

– **Data Analysis and Reporting**: This model allows for comprehensive data collection and analysis, enabling operators to generate detailed reports that can inform future maintenance schedules and operational adjustments.

– **Integration with Distributed Control Systems (DCS)**: The BENTLY Nevada 330102

The above parameters are for reference only. Please contact our technical team for precise selection.

-300x300.jpg?v=1739320885)

There are no reviews yet.