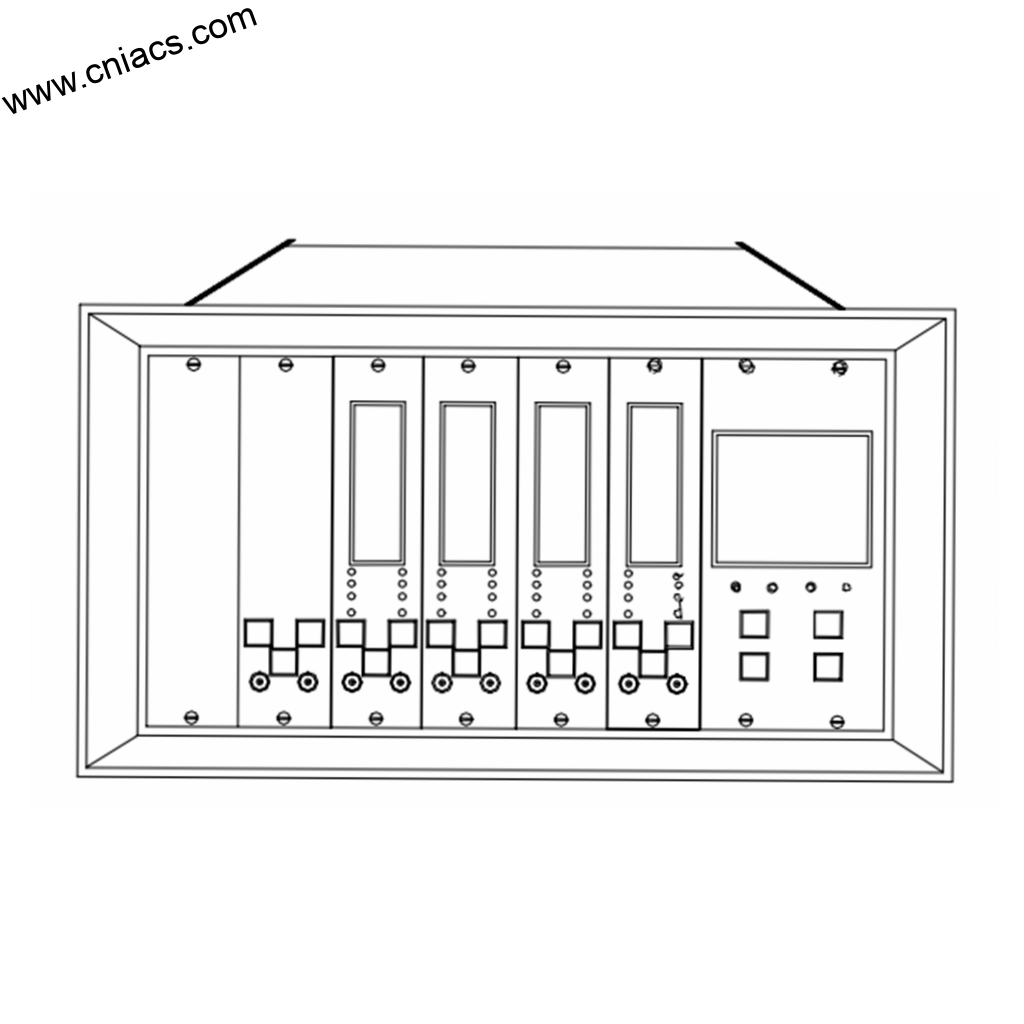

BENTLY Nevada 330106-05-30-10-02-00 Industrial-grade XL 8 mm Reverse Mount Probes for Enhanced Process Monitoring

Introducing the BENTLY Nevada 330106-05-30-10-02-00: a pinnacle of precision and reliability in the realm of industrial automation. Designed for optimal performance in monitoring and protection, this state-of-the-art product exemplifies BENTLY’s commitment to excellence in automation technology.

Key Technical Features

The BENTLY Nevada 330106-05-30-10-02-00 is engineered with advanced features that ensure superior performance and accuracy. At its core, it boasts a high-resolution monitoring system capable of real-time data acquisition, which is essential for predictive maintenance and operational efficiency. This model supports a wide range of sensors, allowing for comprehensive monitoring of vibration, temperature, and other critical parameters.

With a robust communication interface, the 330106-05-30-10-02-00 seamlessly integrates into existing BENTLY automation products and third-party systems, making it extremely versatile. It incorporates advanced algorithms for data analysis, helping to identify potential issues before they escalate into costly failures. Moreover, the model is designed for harsh industrial environments, ensuring durability and reliability even under the most demanding conditions.

Usage Scenarios

The BENTLY Nevada 330106-05-30-10-02-00 is ideal for various applications across multiple industries, including oil and gas, power generation, and manufacturing. In the oil and gas sector, it excels in monitoring rotating machinery such as compressors and turbines, where early detection of mechanical faults can prevent catastrophic failures and downtime.

In power generation, the model plays a crucial role in ensuring the reliability of critical assets, offering continuous monitoring of generator performance and providing insights that enhance operational efficiency. In manufacturing, its capacity to monitor production machinery helps optimize output while minimizing maintenance costs.

The BENTLY Nevada 330106-05-30-10-02-00 is also useful in applications involving condition-based maintenance strategies, allowing organizations to shift from reactive to proactive maintenance. This transition not only enhances equipment longevity but also significantly reduces operational costs.

Comparison with Other Models

When comparing the BENTLY Nevada 330106-05-30-10-02-00 with other models within the BENTLY product line, such as the BENTLY 3500/20 125744-02 and BENTLY 3500/45 176449-04, users will notice distinct advantages in its enhanced data acquisition capabilities and communication features. While the 3500 series is well-regarded for

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY Nevada 330106-05-30-10-02-00 is engineered with advanced features that ensure superior performance and accuracy. At its core, it boasts a high-resolution monitoring system capable of real-time data acquisition, which is essential for predictive maintenance and operational efficiency. This model supports a wide range of sensors, allowing for comprehensive monitoring of vibration, temperature, and other critical parameters.

With a robust communication interface, the 330106-05-30-10-02-00 seamlessly integrates into existing BENTLY automation products and third-party systems, making it extremely versatile. It incorporates advanced algorithms for data analysis, helping to identify potential issues before they escalate into costly failures. Moreover, the model is designed for harsh industrial environments, ensuring durability and reliability even under the most demanding conditions.

Usage Scenarios

The BENTLY Nevada 330106-05-30-10-02-00 is ideal for various applications across multiple industries, including oil and gas, power generation, and manufacturing. In the oil and gas sector, it excels in monitoring rotating machinery such as compressors and turbines, where early detection of mechanical faults can prevent catastrophic failures and downtime.

In power generation, the model plays a crucial role in ensuring the reliability of critical assets, offering continuous monitoring of generator performance and providing insights that enhance operational efficiency. In manufacturing, its capacity to monitor production machinery helps optimize output while minimizing maintenance costs.

The BENTLY Nevada 330106-05-30-10-02-00 is also useful in applications involving condition-based maintenance strategies, allowing organizations to shift from reactive to proactive maintenance. This transition not only enhances equipment longevity but also significantly reduces operational costs.

Comparison with Other Models

When comparing the BENTLY Nevada 330106-05-30-10-02-00 with other models within the BENTLY product line, such as the BENTLY 3500/20 125744-02 and BENTLY 3500/45 176449-04, users will notice distinct advantages in its enhanced data acquisition capabilities and communication features. While the 3500 series is well-regarded for

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.